This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

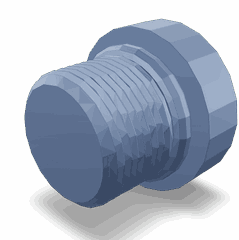

The Cummins 4314451 Threaded Plug is a critical component in commercial truck maintenance, designed to seal openings in engine components. This ensures system integrity and prevents fluid leaks, thereby maintaining the operational efficiency of trucks 2.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems, including engines and hydraulic systems. They prevent the escape of fluids or gases by threading into a port and creating a tight seal. The design allows for easy installation and removal, making them versatile for sealing applications 1.

Purpose of the Cummins 4314451 Threaded Plug

This Cummins part is designed to seal unused ports or openings in engine components. It helps maintain pressure and fluid levels within the engine, ensuring optimal performance. The plug also prevents contaminants from entering the system through unsealed openings, contributing to the engine’s reliability and longevity 2.

Key Features

The Cummins 4314451 Threaded Plug is made from high-quality metal alloys, ensuring resistance to corrosion and wear. It features a specific thread size that matches the ports it is designed to seal, providing a secure fit. The tapered thread profile enhances sealing effectiveness by compressing the plug against the port walls as it is tightened 1.

Benefits

Using this part offers several benefits. It improves system integrity by effectively sealing openings, preventing fluid leaks that could lead to engine damage. The plug’s durable construction ensures enhanced durability under operating conditions, reducing the need for frequent replacements. Its reliable sealing capability contributes to the overall efficiency and performance of the truck’s engine 2.

Installation Process

Installing the Cummins 4314451 Threaded Plug involves cleaning the port, threading the plug into the port using a torque wrench until snug, and checking for leaks by pressurizing the system. It is important to avoid over-tightening to prevent damage to the threads 1.

Troubleshooting Common Issues

Common issues with threaded plugs include leaks and difficulty in removal. If a leak is detected, the plug should be removed and inspected for damage or improper seating. Re-cleaning the port and ensuring the plug is properly threaded can often resolve this issue. Difficulty in removal may be due to corrosion or over-tightening. Applying a penetrating oil and using a plug extractor tool can help in safely removing the plug without causing damage 1.

Maintenance Tips

Regular maintenance of threaded plugs involves periodic inspection for signs of wear or corrosion. Cleaning the plug and port during maintenance intervals can prevent buildup that may affect sealing effectiveness. If the plug shows signs of damage or if leaks are detected, it should be replaced to ensure ongoing performance and system integrity 2.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of engine and powertrain solutions. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance components. The Cummins 4314451 Threaded Plug is part of their extensive product line, designed to meet the demanding requirements of commercial truck applications 1.

Role of Part 4314451 Threaded Plug in Engine Systems

This part serves an integral function in various engine systems, particularly in the context of the pump and raw water components.

Integration with the Pump

In pump systems, the threaded plug is often utilized to seal off specific ports or passages that are not in use during a particular operation. This ensures that the pump operates efficiently by preventing fluid leakage and maintaining system pressure. The plug’s secure fit helps in directing the flow of fluids through the intended pathways, thereby enhancing the overall performance and reliability of the pump 2.

Application in Raw Water Systems

Within raw water systems, the threaded plug plays a significant role in maintaining the integrity of the water passages. It is commonly used to block off sections of the raw water system that may not be required for certain operational conditions. This can include sealing off coolant passages or water jackets when the engine is not in use or during maintenance procedures. The plug ensures that no contaminants enter the system through these blocked passages, preserving the purity of the raw water and protecting the engine components from potential damage 1.

Operational Benefits

The use of the threaded plug in these systems offers several operational benefits. It allows for greater flexibility in system configuration, enabling engineers and mechanics to adapt the engine setup to different operational requirements. Additionally, the plug contributes to the longevity of the engine components by preventing unnecessary wear and tear on parts that are not in active use 2.

Conclusion

The Cummins 4314451 Threaded Plug is a versatile component that enhances the functionality and efficiency of both pump and raw water systems within engine operations. Its durable construction, reliable sealing capability, and ease of installation make it an essential part for maintaining the integrity and performance of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.