This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4314465 Threaded Plug Fitting is a component manufactured by Cummins, a well-established name in the commercial truck industry. This fitting is designed for use in commercial trucks, where it serves a specific function within the vehicle’s system. Understanding its role and application is key to maintaining the efficiency and reliability of truck operations.

Basic Concepts of Threaded Plug Fittings

Threaded plug fittings are mechanical components used to seal openings or passages in various systems. They are characterized by their threaded design, which allows them to be screwed into place, creating a secure seal. These fittings are commonly used in fluid systems to prevent leaks and maintain system integrity. They function by blocking off passages that are not in use or need to be sealed for operational reasons 1.

Purpose of the 4314465 Threaded Plug Fitting

The 4314465 Threaded Plug Fitting plays a role in the operation of a truck by sealing specific openings within the truck’s system. Its primary function is to ensure that fluids or gases do not escape from the system, maintaining the pressure and integrity of the system. This fitting is integral to the truck’s system, ensuring that all components operate within the designed parameters.

Key Features

The 4314465 Threaded Plug Fitting is constructed with specific features that enhance its performance and durability. It is made from materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. The thread type is designed to provide a secure fit, preventing leaks. Additionally, its design specifications are tailored to meet the rigorous demands of commercial truck applications, ensuring reliable performance over time.

Benefits

Using the 4314465 Threaded Plug Fitting offers several advantages. It contributes to improved system integrity by effectively sealing openings, which helps maintain the pressure and functionality of the system. The fitting is designed for ease of installation, reducing downtime during maintenance procedures. Its durable construction ensures long-term reliability, minimizing the need for frequent replacements.

Installation Process

Installing the 4314465 Threaded Plug Fitting requires following a specific procedure to ensure a secure and effective seal. The process involves cleaning the fitting and the opening it will seal to remove any debris. Using the appropriate tools, the fitting is then screwed into place until it reaches the desired tightness. It is important to follow the manufacturer’s guidelines to ensure proper installation 2.

Common Applications

The 4314465 Threaded Plug Fitting is versatile and finds applications in various parts of a truck’s system. It is commonly used in fluid systems where openings need to be sealed to maintain system pressure and prevent leaks. Its application highlights the fitting’s importance in ensuring the efficient operation of the truck.

Troubleshooting and Maintenance

Identifying common issues with threaded plug fittings, such as leaks or loose fittings, is important for maintaining system integrity. Regular inspections and maintenance can help ensure the longevity of the fitting. If a fitting shows signs of wear or damage, it should be replaced following the manufacturer’s guidelines to maintain system reliability.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of commercial applications.

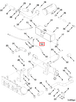

Threaded Plug Fitting 4314465 Compatibility with Cummins Engines

The Threaded Plug Fitting part number 4314465, manufactured by Cummins, is designed to integrate seamlessly with several of their engine models. This fitting is crucial for maintaining the integrity of the engine’s fuel and lubrication systems, ensuring that there are no leaks or disruptions in the flow of essential fluids.

QSK19 CM850 MCRS and QSK60 CM850 MCRS

The QSK19 CM850 MCRS and QSK60 CM850 MCRS engines are part of Cummins’ QSK series, known for their robust performance and reliability in various industrial applications. The 4314465 fitting is specifically engineered to fit these models, providing a secure connection point for threaded plugs. This ensures that the engines can operate efficiently without any risk of fluid leakage, which is critical for maintaining optimal performance and longevity.

QSK50 CM2150 K107

The QSK50 CM2150 K107 engine, another member of the QSK series, also benefits from the use of the 4314465 Threaded Plug Fitting. This engine is designed for heavy-duty applications, and the fitting plays a vital role in its operation by providing a reliable seal for threaded connections. The precision engineering of the 4314465 ensures that it fits perfectly with the QSK50 CM2150 K107, contributing to the engine’s overall durability and efficiency.

Grouping of Engines

While the QSK19 CM850 MCRS and QSK60 CM850 MCRS share similarities in their design and application, the QSK50 CM2150 K107 is tailored for more demanding environments. Despite these differences, the 4314465 fitting is compatible with all three engines, highlighting its versatility and importance in Cummins’ engine lineup. This compatibility ensures that technicians and operators can use the same fitting across multiple engine models, simplifying maintenance and repair processes.

Role of Part 4314465 Threaded Plug Fitting in Engine Systems

In the context of engine systems, the threaded plug fitting, identified as part 4314465, serves a significant function in maintaining the integrity and efficiency of various components.

Integration with the Heat Exchanger

The threaded plug fitting is often utilized in heat exchangers to seal off ports or passages that are not in use. This ensures that the flow of coolant is directed efficiently through the active pathways, optimizing heat transfer and maintaining the desired temperature differential between the engine and the coolant.

Application in the Expansion Tank

In the expansion tank, part 4314465 is employed to cap off openings that are not required for the current operational configuration. This prevents coolant leakage and maintains system pressure, which is essential for the proper functioning of the cooling system.

Role in the Engine Cooling System

Within the broader engine cooling system, the threaded plug fitting helps in isolating sections of the system that may be undergoing maintenance or are not currently in use. This isolation prevents coolant loss and ensures that the active parts of the system can operate without interference.

Function in the Expansion System

The expansion system relies on the threaded plug fitting to manage the volume of coolant as it expands and contracts with temperature changes. By sealing off unnecessary passages, the fitting helps maintain consistent pressure and volume within the system, which is vital for the system’s overall performance.

Contribution to the Expansion Tank

In the expansion tank specifically, the threaded plug fitting is used to seal off bleeder valves or other openings that are not needed during normal operation. This ensures that the tank can effectively manage the excess coolant volume without any unwanted leaks or pressure drops.

By understanding the role of part 4314465 in these various components, engineers and mechanics can better appreciate its importance in maintaining the efficiency and reliability of engine cooling systems.

Conclusion

The 4314465 Threaded Plug Fitting is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its role in sealing openings within various systems ensures the integrity and efficiency of the truck’s operations. Understanding its features, benefits, and proper installation procedures is essential for maintaining system reliability and performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.