This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

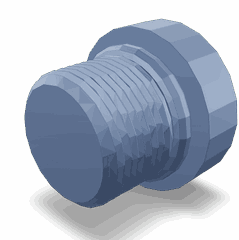

The Cummins 4332468 Threaded Plug is a component designed for use in commercial truck systems. It serves a specific function within the truck’s engine or other systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems. They function by creating a secure, leak-proof connection that prevents the escape of fluids or gases. In automotive systems, threaded plugs are commonly employed in engines, fuel systems, and hydraulic systems to maintain system integrity and prevent contamination 1.

Purpose of the Cummins 4332468 Threaded Plug

The Cummins 4332468 Threaded Plug plays a role in sealing specific openings within a truck’s engine or other systems. Its function is to ensure that fluids or gases remain contained within the system, thereby maintaining operational efficiency and preventing leaks that could lead to system failure or reduced performance.

Key Features

The Cummins 4332468 Threaded Plug is characterized by several key features that enhance its performance and durability. These include its material composition, which is typically designed to withstand high pressures and temperatures, and its thread type, which ensures a secure fit. The design specifications of the plug are tailored to meet the demanding conditions of commercial truck operations.

Benefits

Using the Cummins 4332468 Threaded Plug offers several advantages. It contributes to improved system integrity by providing a reliable seal, enhances performance by preventing leaks, and offers longevity due to its durable construction. These benefits make it a valuable component in maintaining the efficiency and reliability of commercial trucks.

Installation Process

Proper installation of the Cummins 4332468 Threaded Plug involves several steps to ensure a secure fit. The process includes cleaning the installation site, applying the appropriate sealant if required, and using the correct tools to tighten the plug to the specified torque. Following these steps ensures that the plug functions effectively and maintains system integrity.

Common Applications

The Cummins 4332468 Threaded Plug finds typical applications within various truck systems and components. It is commonly used in engine blocks, fuel systems, and hydraulic systems where sealing is critical. Its versatility and reliability make it a preferred choice for these applications.

Troubleshooting and Maintenance

Identifying common issues related to threaded plugs, such as leaks or loose fittings, is important for maintaining system performance. Regular inspection and maintenance can prolong the life of the plug. When replacement is necessary, following the correct procedures ensures that the new plug is installed securely and functions effectively.

Safety Considerations

When working with threaded plugs, observing important safety guidelines and precautions is crucial. This includes proper handling of the plug and tools, adhering to installation practices to prevent over-tightening or under-tightening, and ensuring that the work area is clean and free from contaminants that could affect the plug’s performance.

Cummins Overview

Cummins Inc. is a well-established company with a significant reputation in the commercial truck industry. Founded with a commitment to innovation and quality, Cummins has developed a wide range of components and systems designed to enhance the performance and reliability of commercial vehicles. The company’s expertise and dedication to excellence are reflected in its products, including the Cummins 4332468 Threaded Plug 2.

Compatibility with Cummins Engines

The Threaded Plug 4332468, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is integral to the engine’s operation, ensuring proper sealing and functionality. Here is a detailed look at its compatibility with specific engine models:

QSK60 Series

- QSK60 CM500

- QSK60 CM850 MCRS

The Threaded Plug 4332468 is compatible with both the QSK60 CM500 and QSK60 CM850 MCRS engines. These engines are part of the QSK60 series, known for their robust performance and reliability in various industrial applications. The threaded plug ensures that the engine’s internal components are properly sealed, preventing leaks and maintaining optimal performance.

QSK95 Series

- QSK95 CM2350 K111

- QSK95 CM2350 K113

Similarly, the Threaded Plug 4332468 fits the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. These engines are part of the QSK95 series, which are designed for high-power applications, often found in marine and heavy-duty industrial settings. The threaded plug is crucial in these engines for maintaining the integrity of the engine’s sealing and ensuring that the engine operates efficiently under demanding conditions.

The compatibility of the Threaded Plug 4332468 across these engines underscores its versatility and importance in maintaining the performance and reliability of Cummins engines.

Role in Engine Systems

The Cummins 4332468 Threaded Plug is an essential component in various engine systems, particularly in the management and maintenance of lubricating oil systems. Its primary function is to seal and secure openings within these systems, ensuring the integrity and efficiency of the engine’s lubrication processes.

In the context of the filter system, the Threaded Plug is often used to seal off ports or passages that are not in use. This prevents contaminants from entering the system and ensures that the filtration process remains effective. By securely closing off these areas, the plug helps maintain the cleanliness of the lubricating oil, which is vital for the engine’s performance and longevity.

When it comes to the lubricating oil system, the Threaded Plug plays a significant role in maintaining pressure and preventing leaks. It is commonly installed in bypass valves, pressure relief ports, and other critical points where sealing is necessary. This ensures that the lubricating oil circulates efficiently throughout the engine, reducing friction and wear on moving parts.

In the lubricating oil filter head, the Threaded Plug is used to seal off unused ports or to provide a temporary seal during maintenance procedures. This is particularly important during filter changes or when performing diagnostic checks on the filtration system. The plug ensures that the filter head remains intact and functional, contributing to the overall effectiveness of the filtration process.

Finally, in the lubricating oil filter kit, the Threaded Plug is often included as a versatile component that can be used in various applications within the kit. Whether sealing off ports, providing temporary closures, or ensuring the integrity of the filtration system, the plug is a valuable asset in maintaining the performance and reliability of the engine’s lubricating oil system.

Conclusion

The Cummins 4332468 Threaded Plug is a critical component in the maintenance and operation of commercial truck engines. Its role in sealing and securing various engine systems ensures the efficiency and reliability of the vehicle. Proper installation, regular maintenance, and understanding its applications are key to leveraging the full benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.