This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

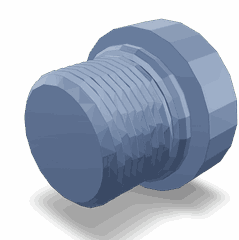

The Cummins 4332471 Threaded Plug is a component designed for use in commercial trucks, specifically within Cummins engine systems. Its purpose is to seal openings in the engine block or other components, preventing the escape of fluids and gases. This part plays a role in maintaining the integrity of the engine’s systems, ensuring efficient operation and longevity of the truck.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal threaded holes in various systems. They function by being screwed into place, creating a tight seal that prevents the leakage of fluids or gases. In automotive and industrial settings, threaded plugs are utilized in engines, hydraulic systems, and other machinery where sealing is necessary to maintain system efficiency and safety 1.

Purpose of the 4332471 Threaded Plug

The Cummins 4332471 Threaded Plug serves a specific function within the truck’s engine or related systems. It is designed to seal openings where fluids or gases need to be contained. By doing so, it helps maintain the pressure and integrity of the system, ensuring that the engine operates efficiently and without leaks.

Key Features

This Cummins part is constructed with specific features that enhance its performance and durability. It is made from materials that resist corrosion and wear, ensuring longevity in harsh operating conditions. The plug features a precise thread type that matches the specifications of Cummins engines, allowing for a secure fit. Its design includes features that facilitate easy installation and removal, while also ensuring a reliable seal.

Benefits

Using the Cummins 4332471 Threaded Plug offers several advantages. It contributes to improved system integrity by effectively sealing openings, which helps prevent fluid leaks. This, in turn, enhances the overall performance of the truck by maintaining the efficiency of the engine and related systems. The plug’s durable construction also ensures long-term reliability, reducing the need for frequent replacements.

Installation Process

Proper installation of the 4332471 Threaded Plug involves several steps to ensure a secure fit. Begin by cleaning the threaded hole to remove any debris or old sealant. Apply a compatible thread sealant to the plug’s threads to enhance the seal. Using the appropriate tools, screw the plug into the hole until it is snug, taking care not to overtighten, which could damage the threads. Verify the seal by checking for any signs of leakage after the engine has been operated.

Troubleshooting Common Issues

Common issues with threaded plugs include leaks and corrosion. If a leak is detected, the plug may need to be removed and re-installed with fresh sealant, or replaced if damaged. Corrosion can be addressed by cleaning the affected area and applying a corrosion-resistant coating. Regular inspections can help identify these issues early, allowing for timely maintenance.

Maintenance Tips

To ensure the longevity and optimal performance of the 4332471 Threaded Plug, regular maintenance is recommended. Inspect the plug during routine engine checks for signs of wear or damage. Cleaning the plug and its surrounding area can prevent the buildup of debris that may affect its sealing capability. Following the manufacturer’s guidelines for inspection intervals and maintenance procedures will help maintain the plug’s effectiveness.

Safety Considerations

When handling and installing the 4332471 Threaded Plug, it is important to observe safety practices to prevent accidents and ensure proper functionality. Use the correct tools and follow the recommended procedures for installation and removal. Wear appropriate personal protective equipment (PPE) to protect against injuries from sharp edges or hot engine components. Ensure the engine is cool before beginning any maintenance or installation work.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance and reliability of commercial vehicles. The Cummins 4332471 Threaded Plug is part of this extensive lineup, reflecting the company’s commitment to quality and durability in its products.

Threaded Plug 4332471 in Cummins Engines

The Threaded Plug 4332471, manufactured by Cummins, is a component in several of their engine models. This part is designed to ensure proper sealing and functionality in various engine systems. Below is a detailed description of how this threaded plug fits into the specified Cummins engines.

QSK60 CM500 and QSK60 CM850 MCRS

In the QSK60 CM500 and QSK60 CM850 MCRS engines, the Threaded Plug 4332471 is utilized in the fuel system. It is essential for maintaining the integrity of the fuel lines and preventing leaks. This plug is typically found in areas where fuel lines connect to the engine’s fuel injection system, ensuring that the fuel flow remains uninterrupted and secure.

QSK95 CM2350 K111 and QSK95 CM2350 K113

For the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the Threaded Plug 4332471 serves a similar purpose but is also used in the engine’s cooling system. This plug is crucial for sealing coolant passages and preventing coolant leaks. It is often installed in the coolant lines or radiator connections, ensuring that the coolant circulates efficiently within the engine without any leaks.

In both sets of engines, the threaded plug is designed to withstand high pressures and temperatures, making it a reliable component in the overall engine assembly. Its robust construction ensures longevity and consistent performance, contributing to the overall efficiency and reliability of the engines.

Role of Part 4332471 Threaded Plug in Engine Systems

The 4332471 Threaded Plug is a component in various engine systems, contributing to the efficient operation and maintenance of these systems.

In the filter system, the threaded plug is often used to seal openings or passages within the filter housing. This ensures that the filtration process remains uncontaminated and that the filter media is effectively contained. It plays a part in maintaining the integrity of the filtration process, which is vital for the longevity and performance of the engine.

Within the lubricating oil system, the threaded plug is utilized to seal off access points or to cap off passages that are not in use. This helps in maintaining the pressure and flow of lubricating oil throughout the engine, ensuring that all moving parts are adequately lubricated. It also aids in preventing leaks, which could lead to a reduction in oil levels and subsequent engine damage.

In the lubricating oil filter head and lubricating oil filter kit, the threaded plug is instrumental in securing components and ensuring that the filter head is properly sealed. This is important for the effective operation of the filter, as it ensures that oil passes through the filter media without bypassing it, thus maintaining the quality of the oil and the efficiency of the lubrication system.

For the pump system, particularly in the context of the water pump and water pump kit, the threaded plug is used to seal off coolant passages or to plug unused ports. This ensures that the coolant system remains pressurized and that the flow of coolant is directed as intended, which is essential for the effective cooling of the engine and the prevention of overheating.

In summary, the 4332471 Threaded Plug, while a small component, plays a role in the sealing and operational integrity of various engine systems. Its application across different components underscores its versatility and importance in maintaining the performance and reliability of engine systems.

Conclusion

The Cummins 4332471 Threaded Plug is a vital component in the maintenance and operation of Cummins engine systems. Its design and features ensure effective sealing of openings, contributing to the overall efficiency and reliability of the engine. Proper installation, regular maintenance, and adherence to safety practices are essential for maximizing the performance and longevity of this part.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.