This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4334011 Threaded Plug, manufactured by Cummins, is a component used in the maintenance and operation of commercial trucks. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts designed to enhance the performance and reliability of heavy-duty trucks. This Cummins part plays a significant role in ensuring the proper functioning of truck systems 1.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings or passages in various systems. They are commonly employed in fluid systems to prevent leaks and maintain system integrity. By screwing into a threaded hole, these plugs create a secure seal, blocking the passage of fluids or gases. Their design allows for easy installation and removal, making them versatile for various applications 2.

Purpose of the 4334011 Threaded Plug

The 4334011 Threaded Plug is specifically designed for use in truck systems where sealing is required. It is applied in areas where fluid passages need to be blocked, such as in engine compartments or hydraulic systems. This plug interacts with the truck’s systems by providing a reliable seal, which is vital for maintaining system pressure and preventing leaks 3.

Key Features

The 4334011 Threaded Plug boasts several key features that enhance its functionality. It is made from durable materials, ensuring longevity and resistance to wear. The plug features a specific thread type that matches the threading in the components it is designed to seal. Additionally, its design may include unique elements that improve its sealing capabilities and ease of installation 4.

Benefits

The use of the 4334011 Threaded Plug offers several benefits. It contributes to improved system integrity by providing a secure seal that prevents fluid leaks. This, in turn, helps maintain system pressure and efficiency. The plug’s reliable performance also enhances the overall reliability of the vehicle, reducing the likelihood of system failures due to leaks 5.

Installation Process

Installing the 4334011 Threaded Plug requires careful attention to ensure a secure fit. The process involves cleaning the threaded hole to remove any debris, applying a suitable sealant if necessary, and screwing the plug into place using the appropriate tools. It is important to follow best practices, such as using a torque wrench to achieve the correct tightening specification, to ensure the plug is properly installed 6.

Troubleshooting Common Issues

Common issues with threaded plugs include leaks and difficulty in removal. If a leak is detected, it may be necessary to remove the plug, inspect the threading for damage, and reapply sealant before reinstalling. Difficulty in removal can often be addressed by using penetrating oil and allowing it to sit for a period before attempting removal again 7.

Maintenance Tips

Regular maintenance of the 4334011 Threaded Plug is important to ensure its continued effectiveness. This includes periodic inspection for signs of wear or damage, such as corrosion or thread damage, which may indicate the need for replacement. Following manufacturer guidelines for inspection intervals can help maintain the plug’s performance and longevity 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial vehicle industry. The company’s extensive product range includes engines, powertrains, and components designed to meet the demanding requirements of commercial trucks and other heavy-duty applications 9.

Threaded Plug 4334011 in Cummins Engines

The Threaded Plug 4334011, manufactured by Cummins, is a critical component in various engine models. This part is designed to ensure proper sealing and functionality within the engine’s system.

QSK19 CM2350 K114

In the QSK19 CM2350 K114 engine, the Threaded Plug 4334011 is utilized to secure and seal specific points within the engine. Its placement is crucial for maintaining the integrity of the engine’s internal systems, ensuring that there are no leaks or pressure losses.

QSK19 CM850 MCRS

Similarly, in the QSK19 CM850 MCRS engine, the Threaded Plug 4334011 serves the same fundamental purpose. It is integral to the engine’s design, providing a reliable seal that is essential for the engine’s performance and longevity.

Grouping of Engines

Both the QSK19 CM2350 K114 and QSK19 CM850 MCRS engines benefit from the use of the Threaded Plug 4334011. This part is designed to fit seamlessly into these engines, ensuring that they operate efficiently and reliably. The threaded design allows for easy installation and removal, making maintenance and repairs more straightforward.

The use of this part across these engines highlights its versatility and importance in Cummins’ engine lineup.

Role of Part 4334011 Threaded Plug in Engine Systems

The 4334011 Threaded Plug is an essential component in various engine systems, particularly those involving filtration and lubrication. Its primary function is to seal and secure specific points within these systems, ensuring the integrity and efficiency of the engine’s operation.

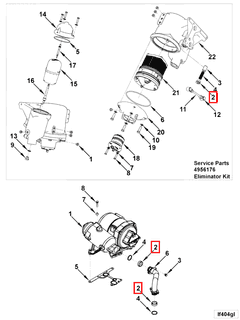

Integration with Filters

In filtration systems, the 4334011 Threaded Plug is often used to seal openings in the Filter. This sealing is vital for maintaining the pressure differential required for effective filtration. By preventing any bypass of unfiltered contaminants, the plug ensures that the Filter performs its role in removing impurities from the engine’s lubricating oil.

Role in Lubricating Oil Systems

Within Lubricating Oil systems, the 4334011 Threaded Plug is employed to seal ports and passages. This is particularly important in maintaining the correct flow and pressure of the Lubricating Oil throughout the engine. Proper sealing helps in preventing oil leaks and ensures that the oil reaches all necessary components for effective lubrication.

Application in Filter Kits

In Filter Kits, which often include multiple filtration components, the 4334011 Threaded Plug plays a role in ensuring the kit’s components are securely assembled. This is essential for the overall performance of the filtration system, as it ensures that each part of the kit functions as intended without any risk of oil leakage or contamination.

Function in Lubricating Oil Filter Heads

The Lubricating Oil Filter Head is another area where the 4334011 Threaded Plug is utilized. Here, it seals the connections between the filter head and the engine’s oil passages. This sealing is important for maintaining the efficiency of the filtration process and ensuring that the Lubricating Oil is clean and free from contaminants before it is circulated through the engine.

Conclusion

In summary, the 4334011 Threaded Plug is a key component in maintaining the efficiency and reliability of engine systems, particularly in areas related to filtration and lubrication. Its role in sealing and securing various components ensures the optimal performance of these systems.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Cummins Inc. (2014). Owners Manual for F2.8 CM2620 F136B. Bulletin Number 5504619.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Cummins Inc. (2014). Owners Manual for F2.8 CM2620 F136B. Bulletin Number 5504619.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Cummins Inc. (2014). Owners Manual for F2.8 CM2620 F136B. Bulletin Number 5504619.

↩ -

Cummins Inc. (2014). Owners Manual for F2.8 CM2620 F136B. Bulletin Number 5504619.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.