This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

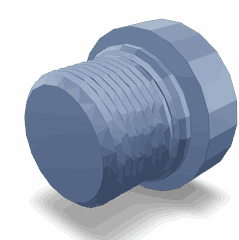

The Cummins Threaded Plug 4893464 is a component designed for use in commercial trucks. Its primary role is to provide a secure seal in various applications within the truck’s system. This plug is integral to maintaining the integrity of the truck’s fluid systems, ensuring that fluids remain contained within their designated pathways without leakage 1.

Purpose and Function

The Threaded Plug 4893464 serves to seal openings in the truck’s system, preventing the escape of fluids and contaminants. It operates by being screwed into place, creating a tight seal that is crucial for the proper functionality of the truck’s systems. This plug is often used in applications where access to certain areas is needed for maintenance or inspection, and then securely sealed afterward 2.

Key Features

The Cummins Threaded Plug 4893464 is constructed from high-quality materials that offer resistance to corrosion and wear. Its threading specifications are designed to ensure a snug fit, reducing the likelihood of leaks. The design of the plug includes features that enhance its performance and durability, such as a robust construction that can withstand the pressures and temperatures encountered in commercial truck operations 3.

Benefits

Using the Cummins Threaded Plug 4893464 offers several advantages. It provides an improved seal compared to other sealing methods, which helps in maintaining the efficiency of the truck’s systems. Its resistance to corrosion ensures longevity, even in harsh operating conditions. Additionally, the durable construction of the plug contributes to its reliability over time.

Installation Process

To install the Threaded Plug 4893464, first, ensure the area where the plug will be installed is clean and free of debris. Use the appropriate tools to screw the plug into place, ensuring it is tightened to the manufacturer’s specifications to achieve a secure fit. It is important to follow best practices during installation to prevent damage to the plug or the surrounding area.

Common Issues and Troubleshooting

Common issues with the Threaded Plug 4893464 may include leaks or damage to the plug. If a leak is detected, it may be necessary to remove the plug and inspect it for damage or improper installation. Troubleshooting may involve cleaning the area, replacing the plug if necessary, or adjusting the installation technique to ensure a better seal.

Maintenance Tips

Regular maintenance of the Threaded Plug 4893464 is important to ensure continued optimal performance. This includes periodic inspection for signs of wear or damage and cleaning the plug and its surrounding area to prevent buildup that could affect its sealing capability. Following manufacturer guidelines for inspection intervals and maintenance procedures will help in preserving the integrity of the plug.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the Threaded Plug 4893464, which is designed to meet the demanding requirements of commercial truck operations.

Threaded Plug 4893464 in Cummins Engines

The Threaded Plug 4893464, manufactured by Cummins, is a critical component in various Cummins engine models. This part is designed to provide a secure and leak-proof seal for threaded openings, ensuring the integrity of the engine’s systems.

ISBE CM800 Engines

In the ISBE CM800 engine series, the Threaded Plug 4893464 is utilized in several key areas. It is commonly found in the fuel system, where it ensures that fuel lines and connections remain sealed, preventing any fuel leaks that could compromise engine performance or safety. Additionally, this plug is used in the coolant system, where it helps maintain the necessary pressure and prevents coolant from escaping, which is vital for the engine’s cooling efficiency.

Grouping of Engines

The Threaded Plug 4893464 is not limited to the ISBE CM800 series but is also compatible with other Cummins engine models. Its design allows it to fit seamlessly in various engine configurations, ensuring that it can be used across different applications without modification. This versatility makes it a valuable component for maintaining the reliability and efficiency of Cummins engines in diverse settings.

Role of Part 4893464 Threaded Plug in Engine Systems

In the intricate network of an engine system, the part 4893464 Threaded Plug assumes a significant role, particularly in the context of the fuel filter and its associated components. This component is instrumental in ensuring the integrity and efficiency of the fuel filtration process.

Integration with Fuel Filter Components

The Threaded Plug is often situated at strategic points within the fuel filter assembly. Its primary function is to seal and secure various connections, preventing any potential leaks that could compromise the fuel system’s performance.

Fuel Filter and Fuel Filter Head

When installed in the fuel filter or the fuel filter head, the Threaded Plug ensures a tight seal, maintaining the pressure within the system. This is essential for the efficient operation of the fuel filter, which relies on consistent pressure to effectively remove impurities from the fuel.

Fuel Filter Bracket Head

In the fuel filter bracket head, the Threaded Plug plays a role in securing the filter in place. This not only aids in the structural stability of the filter but also ensures that the filtration process is uninterrupted and efficient.

Location-Specific Functions

The location of the Threaded Plug within the engine system is carefully chosen to maximize its effectiveness. Whether it’s sealing the connection between the fuel filter and the fuel lines or securing the fuel filter head, its placement is critical for the overall functionality of the fuel system.

Ensuring System Integrity

By effectively sealing these connections, the Threaded Plug contributes to the overall integrity of the fuel system. It prevents fuel leaks, maintains system pressure, and ensures that the fuel reaching the engine is clean and free from contaminants.

Conclusion

The Cummins Threaded Plug 4893464 is a vital component in the maintenance and operation of commercial truck systems. Its role in sealing and securing various connections within the engine and fuel systems ensures the integrity and efficiency of these systems. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, contributing to the overall performance and reliability of the vehicle.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.