This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

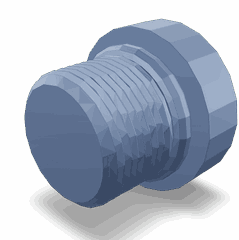

The Cummins Threaded Plug 4931967 is a component designed for use in commercial trucks. Manufactured by Cummins Inc., a leading provider of diesel engines, this threaded plug serves a specific function within various truck systems. Its role is to seal openings, ensuring the integrity and efficiency of the systems it is part of.

Purpose and Function

The Cummins Threaded Plug 4931967 plays a role in the operation of a truck by sealing openings in different systems. This sealing function is vital for maintaining the pressure and fluid levels within these systems, preventing leaks that could lead to inefficiencies or damage. The plug is used in various applications where a secure seal is required to ensure the proper functioning of the truck’s systems.

Key Features

The design of the Cummins Threaded Plug 4931967 includes specific thread types and sizes tailored to fit precisely into the openings it is intended to seal. The material characteristics of the plug are chosen for their durability and resistance to the operating conditions within a truck’s systems. This may include special coatings or treatments to enhance its performance under high temperatures or corrosive environments 1.

Benefits

Using the Cummins Threaded Plug 4931967 offers several advantages. Its design contributes to improved sealing, which is crucial for the efficient operation of the systems it is part of. The plug’s durability ensures it can withstand the rigors of commercial truck use, while its resistance to corrosion and high temperatures makes it suitable for long-term applications in demanding environments 2.

Installation and Usage

Proper installation of the Cummins Threaded Plug 4931967 is key to ensuring its effectiveness. Guidelines for installation include adhering to specified torque values to achieve the correct seal without over-tightening, which could damage the plug or the surrounding components. Preparatory steps may involve cleaning the installation site to remove any debris that could compromise the seal.

Troubleshooting and Maintenance

Common issues with threaded plugs can include leaks or difficulty in removal for maintenance or replacement. Diagnostic steps for identifying problems may involve checking for signs of wear or damage on the plug or the threads it engages with. Maintenance tips to ensure the longevity and proper function of the plug include regular inspection for signs of wear and ensuring it is correctly installed and torqued.

Compatibility and Applications

The Cummins Threaded Plug 4931967 is typically applied within Cummins engines and other systems where a secure seal is required. Its design and specifications make it compatible with a range of applications, ensuring it can be used in various systems across different truck models.

Safety Considerations

When handling and installing the Cummins Threaded Plug 4931967, it is important to observe safety guidelines to prevent injury or damage. This includes using the appropriate tools for installation and removal, ensuring the work area is safe, and following all manufacturer recommendations for use.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its range of diesel engines and components. The company’s history of innovation and quality has earned it a reputation for reliability and performance, making its products, including the Threaded Plug 4931967, a preferred choice for truck manufacturers and fleet operators.

Compatibility with Cummins Engines

The Threaded Plug part number 4931967, manufactured by Cummins, is designed to fit seamlessly within a range of Cummins engines. This part is integral to ensuring the proper sealing and functionality of various engine components.

QSL8.9 CM2150 L141 and QSL9 CM2250

The Threaded Plug 4931967 is compatible with the QSL8.9 CM2150 L141 and QSL9 CM2250 engines. These engines are part of Cummins’ lineup, known for their robust performance and reliability. The threaded plug is used in these engines to secure and seal critical components, ensuring optimal engine operation.

QSL9 CM2350 L102 and QSL9 CM850 (CM2850)

Similarly, the Threaded Plug 4931967 fits the QSL9 CM2350 L102 and QSL9 CM850 (CM2850) engines. These engines are also part of Cummins’ extensive range, designed to meet various industrial and commercial needs. The threaded plug in these engines plays a crucial role in maintaining the integrity of the engine’s sealing and structural components.

By ensuring a secure fit and reliable sealing, the Threaded Plug 4931967 contributes to the overall performance and longevity of these Cummins engines.

Role in Engine Systems

The 4931967 Threaded Plug is a component in various engine systems, particularly in the management and control of oil within the engine. This component is specifically designed to interface with the oil drain plug, ensuring a secure and leak-free connection when draining oil from the oil pan.

When maintaining or servicing an engine, the oil drain plug is unscrewed from the oil pan to allow the old oil to be expelled. The 4931967 Threaded Plug plays a significant role here by providing a reliable seal that prevents oil leakage during normal operation. Its threaded design ensures a tight fit, which is vital for maintaining the integrity of the oil system.

Additionally, the 4931967 Threaded Plug is involved in the process of refilling the oil pan with fresh oil. After the old oil has been drained, the plug is removed, and new oil is poured into the pan. Once the oil level reaches the required mark, the plug is reinserted and tightened to seal the pan, ensuring that the new oil remains contained within the system.

Conclusion

In summary, the Cummins Threaded Plug 4931967 is a key component in the efficient and safe operation of the engine’s oil system, facilitating both the draining and refilling processes while maintaining a secure seal on the oil pan. Its design, durability, and compatibility with various Cummins engines make it an essential part for ensuring the reliability and performance of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.