This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

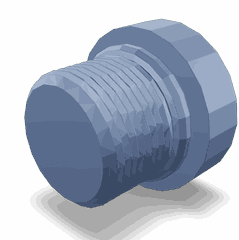

The Cummins 4933177 Threaded Plug is a specialized component designed for use in commercial trucks. It plays a role in maintaining the integrity of various systems within these vehicles, ensuring they operate efficiently and safely. This plug is commonly utilized in the engine and other critical systems, where it helps to seal openings and prevent fluid leaks.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal threaded openings in various systems. They function by being screwed into place, creating a tight seal that prevents the escape of fluids or gases. These plugs are integral to maintaining system pressure and preventing contamination. In mechanical systems, threaded plugs are used in engines, hydraulic systems, and other areas where sealing is necessary 1.

Purpose of the Cummins 4933177 Threaded Plug

This Cummins part is designed to seal openings in the engine or other systems, ensuring that fluids remain contained within their designated pathways. This plug helps maintain system pressure and prevents leaks, which can lead to decreased performance and potential damage to the truck’s components.

Key Features

The 4933177 Threaded Plug boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The plug features a precise thread type that allows for a secure fit, minimizing the risk of loosening over time. Its design characteristics are tailored to withstand the harsh conditions encountered in commercial truck operations.

Benefits

Using the 4933177 Threaded Plug offers several advantages. It contributes to improved system integrity by effectively sealing openings and preventing fluid leaks. This, in turn, enhances operational safety by reducing the risk of system failure due to leaks. Additionally, the plug’s durable construction ensures long-lasting performance, providing reliable protection for the truck’s systems.

Installation Process

Proper installation of the 4933177 Threaded Plug is crucial for ensuring a secure fit and optimal performance. The installation process involves cleaning the threaded opening to remove any debris or contaminants. Using the appropriate tools, the plug is then screwed into place until it reaches the desired tightness. Care should be taken to avoid over-tightening, which can damage the threads.

Common Applications

The 4933177 Threaded Plug finds application in various scenarios and systems within commercial trucks. It is commonly used in the engine to seal openings in the cylinder head, block, or other components. Additionally, it may be employed in hydraulic systems, fuel systems, and other areas where sealing is necessary to maintain system integrity.

Troubleshooting and Maintenance

Identifying common issues related to threaded plugs, such as leaks or loosening, is important for maintaining the truck’s systems. Regular inspection and maintenance can help prolong the lifespan of the plug. If issues arise, the plug may need to be replaced or repaired to ensure continued system integrity and safety.

Safety Considerations

When working with threaded plugs, it is important to observe safety practices to protect oneself and ensure the proper functioning of the truck’s systems. This includes wearing appropriate personal protective equipment (PPE) and following safe handling procedures. Additionally, care should be taken to avoid over-tightening the plug, which can lead to damage and potential system failure.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its high-quality engines and components. With a rich history spanning several decades, Cummins has established itself as a trusted provider of reliable and innovative solutions for commercial vehicles. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of the trucking industry 2.

Threaded Plug 4933177 Compatibility with Cummins Engines

The Cummins part number 4933177, a Threaded Plug, is designed to fit seamlessly with several Cummins engine models. This plug is integral for ensuring the integrity of the engine’s systems, particularly in areas where threaded connections are required.

QSC8.3 CM850 (CM2850) and QSC9 CM2250/QSL9 CM2250

The Threaded Plug 4933177 is compatible with the QSC8.3 CM850 (CM2850) engine. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The plug fits perfectly in the designated areas of this engine, ensuring that all threaded connections are secure and leak-proof.

Similarly, the QSC9 CM2250 and QSL9 CM2250 engines also benefit from the use of this threaded plug. These engines are designed for high-performance applications, and the threaded plug ensures that all connections are tight and secure, preventing any potential leaks or failures.

QSL8.9 CM2150 L141

The QSL8.9 CM2150 L141 engine is another model that is compatible with the Threaded Plug 4933177. This engine is known for its efficiency and power, making it suitable for a variety of demanding applications. The threaded plug fits into the engine’s design, ensuring that all threaded connections are properly sealed and secure.

QSL9 CM850 (CM2850)

Lastly, the QSL9 CM850 (CM2850) engine also utilizes the Threaded Plug 4933177. This engine is designed for heavy-duty use and requires reliable components to maintain its performance. The threaded plug fits into the engine’s design, ensuring that all threaded connections are properly sealed and secure.

By using the Threaded Plug 4933177 in these engines, users can ensure that their engines operate smoothly and efficiently, with all threaded connections properly sealed and secure.

Role of Part 4933177 Threaded Plug in Engine Systems

In engine systems, the 4933177 Threaded Plug is a component that ensures the integrity and functionality of various parts. When integrated with the cover, valve, and valve cover, this threaded plug plays a role in maintaining the engine’s performance and reliability.

Interaction with the Cover

The cover, often used to protect internal engine components from external contaminants, relies on the 4933177 Threaded Plug to create a secure seal. This plug is inserted into designated ports on the cover, preventing any leaks or intrusions that could compromise the engine’s operation. By ensuring a tight fit, the threaded plug helps maintain the cover’s effectiveness in shielding sensitive parts from dirt, moisture, and other debris.

Integration with the Valve

Valves within an engine system regulate the flow of fluids or gases, and the 4933177 Threaded Plug is often used to seal off specific pathways when maintenance or modifications are required. When a valve needs to be isolated from the system, the threaded plug is screwed into place, effectively blocking the flow and allowing technicians to work on other components without interference. This capability is particularly useful during repairs or upgrades, ensuring that the valve’s function remains unaffected by external factors.

Functionality with the Valve Cover

The valve cover, which encases the valve train components, depends on the 4933177 Threaded Plug to maintain a sealed environment. The plug is installed in openings on the valve cover to prevent oil leaks and maintain proper pressure within the engine. This sealing function is vital for the valve cover’s role in protecting the valves, camshaft, and other upper engine components. By ensuring a leak-free system, the threaded plug contributes to the overall efficiency and longevity of the engine.

Conclusion

In summary, the 4933177 Threaded Plug is a versatile component that enhances the functionality and reliability of the cover, valve, and valve cover within engine systems. Its ability to create secure seals and isolate components makes it an indispensable part of maintaining optimal engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.