This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

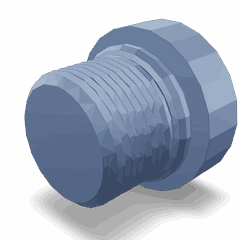

The Cummins 4947074 Threaded Plug is a component designed for use in commercial trucks. It serves a specific function within the truck’s systems, contributing to the overall maintenance and operational efficiency of the vehicle. Understanding its purpose and significance can aid in the proper upkeep and performance of commercial trucks.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems, including automotive applications. They function by being screwed into place, creating a secure seal that prevents fluids or gases from escaping. These plugs are utilized in a range of applications, from engine compartments to fuel systems, providing a reliable method for sealing and protecting internal components 1.

Purpose of the Cummins 4947074 Threaded Plug

The Cummins 4947074 Threaded Plug plays a role in sealing specific openings within a truck’s engine or other systems. Its function is to ensure that fluids or gases remain contained within their designated pathways, preventing leaks that could lead to system inefficiencies or failures. By maintaining the integrity of these seals, the plug contributes to the smooth operation of the truck 4.

Key Features

The Cummins 4947074 Threaded Plug is characterized by several key features that enhance its performance and durability. These include its material composition, which is selected for resistance to corrosion and wear, and its thread type, which ensures a secure fit. The design specifications of the plug are tailored to meet the demands of its application, providing reliable sealing under various operating conditions 2.

Benefits of Using the Cummins 4947074 Threaded Plug

Utilizing the Cummins 4947074 Threaded Plug offers several advantages. It provides improved sealing capabilities, which help maintain system integrity and efficiency. The plug’s resistance to corrosion ensures longevity, even in harsh operating environments. Additionally, its compatibility with Cummins engines ensures that it meets the stringent requirements for performance and reliability in commercial truck applications 3.

Installation Process

Proper installation of the Cummins 4947074 Threaded Plug involves several steps to ensure a secure fit. The process includes preparing the installation site, using the appropriate tools to screw the plug into place, and verifying that the seal is intact. Precautions should be taken to avoid over-tightening, which could damage the plug or the surrounding components 1.

Common Issues and Troubleshooting

Threaded plugs, including the Cummins 4947074, may encounter issues such as leaks or damage over time. Common problems can often be traced to improper installation, wear and tear, or exposure to corrosive substances. Troubleshooting these issues may involve inspecting the plug and its seating, cleaning or replacing the plug as necessary, and ensuring that all components are compatible and correctly installed 4.

Maintenance Tips

To prolong the life of the Cummins 4947074 Threaded Plug, regular maintenance practices are recommended. This includes periodic inspections to check for signs of wear or damage, cleaning the plug and its seating to remove any debris or contaminants, and replacing the plug according to manufacturer guidelines or when signs of failure are detected. Adhering to these practices can help maintain the plug’s effectiveness and the overall performance of the truck 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its product offerings, including the Cummins 4947074 Threaded Plug, which is designed to meet the high standards of performance and reliability expected in commercial truck applications 3.

Cummins Engine Threaded Plug 4947074 Compatibility

The Cummins Threaded Plug 4947074 is a versatile component designed to fit a range of Cummins engines. This plug is integral to various engine models, ensuring secure sealing and efficient operation. Below is a detailed breakdown of the engines compatible with this threaded plug:

B4.5 Series

- B4.5 CM2350 B129B

- ISB4.5 CM2350 B104

D4.0 Series

- D4.0 CM2620 D103B

F3.8 Series

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

F4.5 Series

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

- ISF4.5 CM2220 F123

QSF2.8 Series

- QSF2.8 CM2880 F104

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F108

- QSF2.8 CM2880 F114

QSF3.8 Series

- QSF3.8 CM2350 F107

- QSF3.8 CM2880 F112

F3.8 Series (Additional)

- F3.8 CM2620 F137B

- F3.8 F102

This threaded plug is engineered to meet the specific requirements of these engines, ensuring compatibility and reliability across various models. Its design allows for seamless integration, providing a secure fit that is essential for maintaining engine performance and integrity 3.

Role of Part 4947074 Threaded Plug in Engine Systems

The part 4947074 Threaded Plug is a component in various engine systems, ensuring the integrity and functionality of several critical parts.

In the housing of an engine, the Threaded Plug is utilized to seal openings, preventing the escape of fluids or gases. This is particularly important in maintaining the pressure and efficiency of the system.

When integrated with the thermostat, the Threaded Plug helps in sealing the thermostat housing, ensuring that the coolant flow is regulated effectively. This regulation is vital for maintaining optimal engine temperature and preventing overheating.

In the lubricating oil pump system, the Threaded Plug is employed to seal ports and passages. This ensures that the lubricating oil is delivered consistently to all moving parts, reducing friction and wear.

For plumbing applications within the engine, the Threaded Plug is used to cap off unused lines or to seal connections, ensuring that the fluid dynamics within the system remain undisturbed.

In the cabin heater system, the Threaded Plug plays a role in sealing the heater core and associated passages. This ensures that hot coolant is effectively circulated to provide warmth to the cabin without any leaks.

Similarly, in the broader pump systems, whether for fuel, coolant, or other fluids, the Threaded Plug is used to seal inlets and outlets, maintaining the pressure and flow necessary for efficient operation.

Lastly, within the thermostat housing assembly, the Threaded Plug is crucial for sealing the housing, ensuring that the thermostat can function correctly in regulating the flow of coolant based on engine temperature.

Overall, the part 4947074 Threaded Plug is a versatile component that enhances the reliability and performance of various engine systems by providing effective seals and preventing fluid or gas leakage 4.

Conclusion

The Cummins 4947074 Threaded Plug is a critical component in the maintenance and operation of commercial trucks. Its role in sealing various engine systems ensures the integrity and efficiency of the vehicle. Understanding its features, benefits, and proper installation and maintenance practices can significantly contribute to the longevity and performance of commercial trucks. Cummins’ commitment to quality and innovation is evident in the design and functionality of this part, making it a reliable choice for commercial truck applications.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ ↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ ↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 4383695.

↩ ↩ ↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.