This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

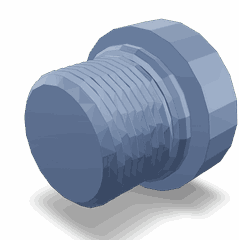

The 4951825 Threaded Plug is a component manufactured by Cummins, a well-established name in the commercial truck industry. This plug serves a specific function within the operational framework of commercial trucks, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Threaded Plugs

A threaded plug is a fastener designed to seal openings in various systems, preventing the escape of fluids or gases. It consists of a cylindrical body with external threads that screw into a corresponding threaded hole. In automotive and industrial applications, threaded plugs are utilized to seal off unused ports, prevent leaks, and maintain system integrity 1.

Purpose of the 4951825 Threaded Plug

The 4951825 Threaded Plug is specifically designed to play a role in sealing applications within a truck’s engine or other systems. It is used to close off openings where a component may have been removed or is not in use, ensuring that the system remains sealed and functions correctly. This plug helps maintain the pressure and fluid levels within the system, contributing to the engine’s overall performance and longevity 2.

Key Features

This Cummins part is constructed from high-quality materials, ensuring durability and resistance to corrosion. It features a precise thread type that allows for a secure fit within the designated openings. Unique design elements, such as a tapered seal or specialized coating, may be incorporated to enhance its sealing capabilities and performance under various operating conditions 3.

Benefits

Utilizing the 4951825 Threaded Plug offers several advantages. Its robust construction ensures longevity, reducing the need for frequent replacements. The plug’s design facilitates ease of installation, allowing for quick and efficient sealing of openings. Additionally, its reliability in sealing applications contributes to the overall efficiency and safety of the truck’s systems.

Installation Process

Installing the 4951825 Threaded Plug requires careful attention to detail to ensure a secure fit. The process involves cleaning the threaded hole to remove any debris, applying a thread sealant if necessary, and screwing the plug into place using the appropriate tools. It is important to follow best practices, such as not over-tightening the plug, to avoid damaging the threads and ensure a proper seal.

Common Applications

The 4951825 Threaded Plug finds its use in various critical areas within a truck, such as the engine block, transmission, and other systems where sealing is required. Its versatility and reliability make it a preferred choice for sealing applications across different truck models and engine types.

Troubleshooting and Maintenance

Identifying common issues with the 4951825 Threaded Plug, such as leaks or corrosion, is important for maintaining system integrity. Regular inspections and maintenance, including checking for proper seating and signs of wear, can help prolong the plug’s lifespan. Addressing issues promptly ensures continued reliability and performance of the truck’s systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name among professionals in the field.

Threaded Plug 4951825 in Cummins Engines

The Threaded Plug 4951825, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the engine’s operation, ensuring that various systems function correctly by providing a secure and leak-proof seal.

QSK45 CM500 and QSK60 CM850 MCRS

In the QSK45 CM500 and QSK60 CM850 MCRS engines, the Threaded Plug 4951825 is used to seal off specific sections of the engine. These engines are known for their robust design and high performance, often used in heavy-duty applications such as marine and industrial settings. The threaded plug ensures that the internal pressure is maintained, preventing any leaks that could compromise engine performance or safety.

QSK95 CM2350 K111

The QSK95 CM2350 K111 engine, part of Cummins’ high-output range, also utilizes the Threaded Plug 4951825. This engine is designed for demanding applications, including power generation and large-scale industrial operations. The threaded plug in this engine plays a crucial role in maintaining the integrity of the fuel and lubrication systems, ensuring that the engine operates at peak efficiency.

Compatibility and Installation

The Threaded Plug 4951825 is designed to fit seamlessly into the specified engine models, providing a reliable and durable solution for sealing purposes. Its threaded design allows for easy installation and removal, making it a convenient choice for maintenance and repairs. The plug’s material and construction are tailored to withstand the harsh conditions and high pressures found within these engines, ensuring longevity and consistent performance.

Understanding the Role of Part 4951825 Threaded Plug in Engine Systems

In the intricate world of engine systems, each component plays a specific role in ensuring optimal performance and efficiency. The part 4951825 Threaded Plug is one such component that, while seemingly minor, contributes significantly to the overall functionality of various engine components.

Integration with the Cylinder Head and Camshaft

The Threaded Plug is often utilized in the cylinder head, where it helps in sealing off unused passages or ports. This sealing is essential for maintaining the integrity of the engine’s airflow and fuel delivery systems. When integrated with the camshaft, the Threaded Plug ensures that the valve train operates within the designed parameters, contributing to consistent engine performance.

Role in the Cylinder Top Level Assembly Head

In the cylinder top level assembly head, the Threaded Plug serves as a barrier to prevent the ingress of contaminants into the engine’s internal components. This is particularly important in high-performance engines where precision and cleanliness are paramount. By sealing off unnecessary openings, the Threaded Plug helps maintain the engine’s performance parts in pristine condition.

Interaction with Injectors and Wiring Retainer Brackets

The Threaded Plug also plays a role in the management of injectors within the engine system. By sealing off specific ports, it ensures that fuel is delivered precisely where needed, enhancing the engine’s efficiency and power output. Additionally, in conjunction with wiring retainer brackets, the Threaded Plug helps in organizing and securing wiring, reducing the risk of electrical issues that could affect engine performance.

Contribution to Overall Engine Performance

Beyond its specific applications, the Threaded Plug contributes to the overall performance of the engine by ensuring that all components work in harmony. Its role in sealing and organizing is fundamental to maintaining the engine’s designed performance levels, making it an indispensable part in the engine’s complex system.

Conclusion

The 4951825 Threaded Plug is a vital component in the maintenance and optimization of commercial truck engines. Its role in sealing various systems ensures the integrity and efficiency of the engine, contributing to the overall performance and longevity of the vehicle. Understanding and properly maintaining this part is essential for professionals in the automotive industry to ensure the reliability and safety of their vehicles.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.