This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

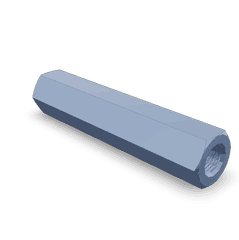

The 4978624 Threaded Spacer by Cummins is a component designed to enhance the operation of commercial trucks. This spacer plays a role in maintaining proper spacing and alignment within various truck systems, contributing to the overall efficiency and reliability of the vehicle.

Basic Concepts of Threaded Spacers

Threaded spacers are mechanical components used to create and maintain specific distances between parts in an assembly. They function by providing a threaded interface that allows for secure attachment and adjustment. These spacers are commonly used in various mechanical systems to ensure components are properly aligned and spaced, which is vital for the optimal performance and longevity of the machinery 1.

Purpose of the 4978624 Threaded Spacer

The 4978624 Threaded Spacer is specifically designed to play a role in the operation of commercial trucks by ensuring precise spacing and alignment within the engine or other critical systems. This spacer helps in maintaining the correct clearances between components, which is important for the efficient functioning of the truck’s mechanical systems.

Key Features

The 4978624 Threaded Spacer boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The spacer features a specific thread type that allows for secure and reliable attachment. Its dimensions are precisely engineered to fit within the designated applications, and it may include unique design elements that further improve its functionality.

Benefits

The 4978624 Threaded Spacer offers several benefits, including improved performance and durability. By ensuring proper spacing and alignment, it helps in reducing wear and tear on adjacent components. This can lead to enhanced efficiency and reliability of the truck’s systems. Additionally, the durable construction of the spacer contributes to its longevity, providing cost-saving advantages over time.

Installation Process

Installing the 4978624 Threaded Spacer requires careful attention to detail to ensure proper fitting. The process involves cleaning the installation area to remove any debris, applying a suitable lubricant to the threads, and using the appropriate tools to securely fasten the spacer in place. It is important to follow the manufacturer’s guidelines to ensure the spacer is correctly installed and functions as intended.

Troubleshooting Common Issues

Common issues with threaded spacers can include improper fitting, thread damage, or misalignment. To address these problems, it is important to inspect the spacer and the surrounding components for any signs of wear or damage. Ensuring the threads are clean and lubricated can help prevent issues during installation. If misalignment is detected, re-evaluating the installation process and making necessary adjustments can resolve the problem.

Maintenance Tips

Regular maintenance of the 4978624 Threaded Spacer is important to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the spacer to remove any buildup, and ensuring it remains securely fastened. Following these maintenance practices can help prevent issues and ensure the spacer continues to function effectively.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. With a rich history of innovation and a diverse product range, Cummins has established a strong reputation for reliability and performance. The company’s commitment to excellence is reflected in its products, including the 4978624 Threaded Spacer, which is designed to meet the demanding requirements of commercial truck applications.

Threaded Spacer 4978624 in Cummins Engines

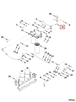

The Threaded Spacer 4978624, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the assembly and functionality of the engines, ensuring proper spacing and alignment between various engine parts.

QSK19 and CM850 Engines

In the QSK19 and CM850 engines, the Threaded Spacer 4978624 is used to maintain the correct distance between the cylinder head and the engine block. This precise spacing is crucial for the engine’s performance and longevity, as it ensures that the cylinder head is properly sealed and aligned with the block. The threaded design allows for easy installation and adjustment, making it a reliable choice for these high-performance engines.

MCRS Engines

For the MCRS engines, the Threaded Spacer 4978624 serves a similar purpose, maintaining the necessary gap between the engine block and other critical components. This part is essential in ensuring that the engine operates smoothly and efficiently, as it helps to prevent misalignment and potential damage to the engine’s internal parts.

Grouping of Engines

The Threaded Spacer 4978624 is compatible with the QSK19, CM850, and MCRS engines, making it a versatile component in Cummins’ engine lineup. Its use across these models highlights its importance in maintaining the structural integrity and performance of the engines.

Role of Part 4978624 Threaded Spacer in Engine Systems

In the context of engine systems, the part 4978624 Threaded Spacer is instrumental in maintaining the precise alignment and spacing between various components. This ensures optimal performance and longevity of the engine.

Fuel System Integration

Within the fuel system, the Threaded Spacer is often positioned between the fuel filter and the fuel pump. Its role here is to maintain the correct distance and alignment, which is essential for the efficient flow of fuel. Proper spacing ensures that the fuel filter can effectively remove contaminants without restricting the fuel flow to the pump. This, in turn, allows the fuel pump to deliver a consistent and clean fuel supply to the engine, enhancing combustion efficiency and overall engine performance 2.

Filter Assembly Application

In filter assemblies, the Threaded Spacer is used to secure the filter elements in place. It ensures that the filter media is held at the correct distance from the housing, allowing for maximum filtration efficiency. This is particularly important in high-performance engines where even the smallest particles can cause significant damage. The spacer helps in maintaining the structural integrity of the filter assembly, ensuring that it functions as intended under various operating conditions.

General Engine System Usage

Across various engine systems, the Threaded Spacer serves as a vital component in maintaining the structural integrity and functional alignment of different parts. Whether it is used in the fuel system or filter assemblies, its role in ensuring precise spacing and alignment cannot be overstated. This contributes to the smooth operation of the engine, reducing wear and tear on components, and promoting efficient performance 3.

Conclusion

The 4978624 Threaded Spacer by Cummins is a critical component in the operation of commercial trucks, particularly within Cummins’ engine models such as the QSK19, CM850, and MCRS. Its role in maintaining precise spacing and alignment between various engine components ensures optimal performance and longevity. The spacer’s durable construction and precise engineering make it a reliable choice for high-performance engines, contributing to the overall efficiency and reliability of the vehicle.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

Vehicle Dynamics: Theory and Application, Reza N. Jazar, Springer, 2017

↩ -

Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Wiley-ISTE, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.