This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Threaded Plug 4994692 by Cummins is a specialized component designed for use in commercial truck operations. This plug serves a vital role in maintaining the integrity and functionality of various truck systems by providing secure sealing in designated areas. Understanding its purpose and function is key to appreciating its importance in the maintenance and operation of commercial vehicles.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in automotive systems. They function by being screwed into a threaded hole, creating a tight seal that prevents fluid or gas leakage. These plugs are commonly employed in engine blocks, transmission cases, and other critical areas where sealing is necessary. The materials used in their construction typically include metals such as brass, steel, or aluminum, chosen for their durability and resistance to corrosion. Standard threading types vary, with UNF (Unified National Fine) and UNC (Unified National Coarse) being common in automotive applications 1.

Purpose of Threaded Plug 4994692

The Threaded Plug 4994692 is specifically designed to fit into various components within truck systems, contributing to the sealing and structural integrity of these parts. It is utilized in areas where openings need to be sealed off, such as unused ports or passages within the engine or transmission. By providing a secure seal, this plug helps maintain the pressure and fluid levels necessary for optimal system performance 2.

Key Features

The Threaded Plug 4994692 boasts several key features that enhance its performance and durability. Its design incorporates precise threading to ensure a tight fit and effective sealing. Constructed from high-quality materials, it offers excellent resistance to corrosion and wear, ensuring longevity in demanding commercial truck environments. Additionally, its design may include features such as a tapered seat to improve sealing efficiency or a hex head for easy installation and removal.

Benefits

Utilizing the Threaded Plug 4994692 in truck maintenance and operation offers several advantages. It provides improved system sealing, which is crucial for maintaining the efficiency and reliability of truck systems. The ease of installation, thanks to its threaded design, allows for quick replacement or sealing of openings without the need for specialized tools. Its durability and resistance to corrosion ensure that it can withstand the harsh conditions encountered in commercial truck operations, reducing the need for frequent replacements 3.

Troubleshooting and Maintenance

Identifying common issues with threaded plugs, such as leaks or damage, is important for maintaining system integrity. Regular inspection for signs of wear, corrosion, or loosening can help prevent more serious problems. Maintenance practices should include checking the condition of the plug and its seating area, ensuring there is no damage that could compromise the seal. Replacement should be performed according to manufacturer guidelines to ensure proper fit and function 4.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and aftermarket parts. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and innovation is evident in its extensive product range, designed to meet the demanding requirements of commercial vehicle operations.

Compatibility with Cummins Engines

This Cummins part is designed to fit a variety of Cummins engines, ensuring a secure and reliable seal in different applications. Here is a detailed overview of its compatibility with various engine models:

B Series Engines

- B4.5 CM2350 B135B

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

D Series Engines

- D4.0 CM2620 D103B

F Series Engines

- F2.8 CM2620 F135B

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F3.8 F102

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

ISB Series Engines

- ISB4.5 CM2350 B104

- ISB6.7 G CM2180 B118

ISF Series Engines

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

- ISF4.5 CM2220 F123

QSF Series Engines

- QSF2.8 CM2880 F104

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F108

- QSF2.8 CM2880 F114

- QSF3.8 CM2350 F107

- QSF3.8 CM2880 F112

This threaded plug is engineered to provide a precise fit and reliable sealing for the specified engines, ensuring optimal performance and longevity.

Role of Threaded Plug 4994692 in Engine Systems

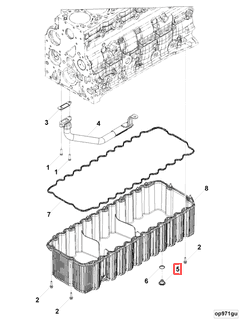

In the context of engine systems, the 4994692 Threaded Plug is instrumental in ensuring the integrity and functionality of various components. When integrated into an oil pan or an oil pan kit, this threaded plug serves as a seal to prevent oil leakage, maintaining the necessary oil levels for engine lubrication.

The pan component, which is typically the lower part of the engine that houses the oil, relies on the threaded plug to create a secure closure. This is essential for preventing oil spillage and contamination, which could otherwise lead to engine damage.

Furthermore, the relationship between the threaded plug and the oil itself is significant. By ensuring a tight seal, the plug helps in maintaining the correct oil pressure within the engine. This is vital for the efficient operation of the engine, as proper oil pressure is necessary for the lubrication of moving parts, reduction of friction, and overall engine performance.

Conclusion

In summary, the 4994692 Threaded Plug plays a key role in the maintenance and operation of engine systems by ensuring the secure containment of oil within the pan, thereby contributing to the engine’s longevity and efficiency.

-

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Hilgers, Michael, and Wilfried Achenbach. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Cummins Inc. Operation and Maintenance Manual for ISM and ISMe Engines. Bulletin Number 3666319.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.