This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

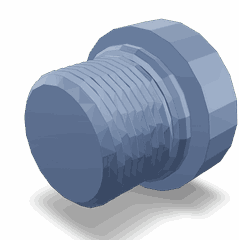

The Cummins 5259558 Threaded Plug is a component designed for use in commercial truck operations. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems. They consist of a threaded section that screws into a corresponding threaded hole, creating a secure seal. In automotive and industrial applications, threaded plugs are utilized to prevent fluid leaks, protect against contaminants, and maintain system integrity. They are commonly found in engine blocks, transmission systems, and hydraulic circuits 1.

Purpose of the Cummins 5259558 Threaded Plug

The Cummins 5259558 Threaded Plug is specifically designed to seal openings within a truck’s engine or other systems. Its primary function is to prevent the escape of fluids or gases, ensuring that the system operates efficiently. By maintaining a secure seal, the plug contributes to the overall performance and longevity of the truck’s components 2.

Key Features

The Cummins 5259558 Threaded Plug is engineered with several key features that enhance its performance and durability. It is typically made from high-quality materials that resist corrosion and wear. The plug features a specific thread type that ensures a tight fit within the designated opening. Its design specifications are tailored to withstand the harsh conditions often encountered in commercial truck operations.

Benefits

Using the Cummins 5259558 Threaded Plug offers several advantages. It provides improved sealing capabilities, which help prevent leaks and maintain system pressure. The plug’s resistance to corrosion ensures longevity, even in challenging environments. Additionally, its durable construction contributes to the overall reliability of the truck’s systems 3.

Installation Process

Proper installation of the Cummins 5259558 Threaded Plug is crucial for ensuring a secure fit and optimal performance. The process involves cleaning the threaded hole to remove any debris, applying a thread sealant if necessary, and screwing the plug into place using the appropriate tools. It is important to follow manufacturer guidelines to achieve the correct torque specifications and ensure a leak-free seal.

Common Applications

The Cummins 5259558 Threaded Plug is commonly used in various systems within commercial trucks. It can be found in engine blocks to seal openings where fluids or gases may escape. Additionally, it is utilized in transmission systems and hydraulic circuits to maintain system integrity and prevent leaks.

Troubleshooting and Maintenance

Identifying common issues related to threaded plugs, such as leaks or damage, is important for maintaining the plug’s performance. Regular inspection and maintenance can help prolong the life of the plug and ensure optimal system operation. If a leak is detected, the plug may need to be replaced or resealed to restore system integrity.

Safety Considerations

When handling and installing the Cummins 5259558 Threaded Plug, it is important to observe safety guidelines to prevent injuries or equipment damage. This includes wearing appropriate personal protective equipment, using the correct tools for installation, and following manufacturer recommendations for torque specifications. Additionally, ensuring that the plug is properly seated and sealed is crucial for safe and efficient operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck and engine industry. The company offers a wide range of products and services designed to meet the needs of customers in various industries, including transportation, construction, and agriculture.

Compatibility with Cummins Engines

The Threaded Plug 5259558, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral for sealing and securing certain components within the engine, ensuring optimal performance and reliability. Below is a detailed breakdown of the engines with which this threaded plug is compatible:

B4.5 CM2350 B129B

This engine variant utilizes the threaded plug for securing specific components, ensuring that the engine operates smoothly and efficiently.

F3.8 CM2350 F120B, F3.8 CM2620 F137B, F3.8 F102, F4.5 CM2620 F139B

These engines share a commonality in their use of the threaded plug for various sealing and securing applications. The threaded plug is crucial in maintaining the integrity of the engine’s internal components.

ISB4.5 CM2350 B104, ISF3.8 CM2220 AN, ISF3.8 CM2220 F103, ISF3.8 CM2350 F109, ISF4.5 CM2220 F123

These engines also rely on the threaded plug for essential sealing and securing functions. The plug’s design ensures that the engine’s components remain tightly sealed, preventing leaks and maintaining performance.

ISX12 G CM2180 EJ, QSF3.8 CM2350 F107

The threaded plug is equally important in these engines, providing the necessary sealing and securing for optimal engine operation. Its design ensures that the engine’s components are held firmly in place, contributing to the engine’s overall reliability and efficiency.

By using the threaded plug 5259558 in these engines, Cummins ensures that the engines maintain their performance and reliability, providing a seamless and efficient operation.

Role of Part 5259558 Threaded Plug in Engine Systems

The part 5259558 Threaded Plug is an essential component in various engine systems, facilitating the secure sealing of openings and passages. In the Air Control Valve system, this threaded plug ensures that the valve housing remains sealed, preventing any unwanted air leaks that could disrupt the air-fuel mixture and affect engine performance.

Within the Air Intake Manifold, the threaded plug is used to seal off unused ports or passages, maintaining the integrity of the intake system and ensuring optimal airflow to the engine cylinders.

In the Cooler systems, such as the Engine Oil Cooler and Lubricating Oil Cooler Module, the threaded plug plays a significant role in sealing connections and passages. This ensures that the cooling fluid circulates efficiently without any leaks, which is vital for maintaining the engine’s operating temperature within safe limits.

The Fuel Control Module and Fuel Control systems also benefit from the use of the threaded plug. It seals off any unnecessary openings in the module, ensuring that the fuel delivery system operates efficiently and without leaks, which is important for both performance and safety.

In the Lubricating Oil Cooler Module, the threaded plug is used to seal connections and passages, ensuring that the lubrication system remains intact and functions correctly. This is important for reducing friction and wear within the engine components.

The Plumbing system within the engine also utilizes the threaded plug to seal various connections and passages. This ensures that fluids, whether they be coolant, oil, or fuel, are directed correctly throughout the engine without any leaks.

Lastly, in the Compressor Coolant system, the threaded plug is used to seal off any unused or unnecessary passages, ensuring that the coolant circulates efficiently through the compressor, which is essential for maintaining its performance and longevity.

Conclusion

The Cummins 5259558 Threaded Plug is a vital component in maintaining the efficiency and reliability of commercial truck engines. Its role in sealing various systems ensures that the engine operates smoothly, prevents leaks, and maintains optimal performance. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010

↩ -

Introduction to Internal Combustion Engines, Fourth Edition, Richard Stone, Macmillan, 2012

↩ -

Transmissions and Drivetrain Design, Michael Hilgers, Springer Vieweg, 2022

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.