This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

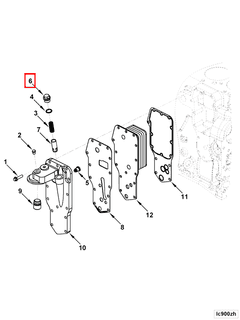

The Cummins 5273979 Threaded Plug is a component designed for use in commercial truck systems. Its primary role is to provide a secure seal in various applications, ensuring the integrity and efficiency of the system it is part of. This plug is integral to maintaining the operational standards of commercial trucks by preventing leaks and protecting internal components from contaminants.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in pipes, engine blocks, and other equipment. They function by being screwed into a threaded hole, creating a tight seal that prevents fluid or gas leakage. In automotive and industrial systems, threaded plugs are commonly employed to cap off unused ports, seal system boundaries, and protect sensitive components from environmental factors 1.

Purpose of the Cummins 5273979 Threaded Plug

The Cummins 5273979 Threaded Plug serves a specific role in the operation of commercial trucks. It is designed to seal and protect various components within the truck’s system. By fitting securely into threaded holes, it prevents the escape of fluids or gases and shields internal parts from dirt, moisture, and other contaminants. This function is vital for maintaining the efficiency and longevity of the truck’s components 2.

Key Features

The Cummins 5273979 Threaded Plug is characterized by several key features that enhance its performance and durability. It is made from high-quality materials that resist corrosion and wear, ensuring a long service life. The plug features a specific thread type that matches the requirements of its application, allowing for a secure fit. Its design is tailored to meet the demands of commercial truck systems, providing reliable sealing under various operating conditions 3.

Benefits

Using the Cummins 5273979 Threaded Plug offers several benefits. It contributes to improved system integrity by ensuring that fluids and gases remain contained within their designated pathways. This enhances the safety and efficiency of the truck’s operation. Additionally, by protecting internal components from contaminants, the plug helps prolong the life of these parts, reducing the need for frequent maintenance or replacement.

Installation Process

Installing the Cummins 5273979 Threaded Plug requires careful attention to ensure a correct fit. The process involves cleaning the threaded hole to remove any debris, applying a compatible sealant to the threads if necessary, and screwing the plug into place using the appropriate tools. It is important to follow manufacturer guidelines to avoid over-tightening, which could damage the plug or the surrounding components.

Common Applications

The Cummins 5273979 Threaded Plug finds applications in various parts of commercial truck systems. It is commonly used in engine blocks to seal off unused ports, in transmission housings to prevent fluid leaks, and in hydraulic systems to maintain pressure and prevent contamination. Its versatility makes it a valuable component across different truck models and engine types.

Troubleshooting and Maintenance

Identifying common issues with threaded plugs, such as leaks or corrosion, is important for maintaining system efficiency. Regular inspections can help detect these problems early. Maintenance practices, such as cleaning the plug and its surrounding area, applying fresh sealant when necessary, and ensuring it is properly tightened, can ensure the longevity and proper function of the plug.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications, from commercial trucks to industrial equipment.

Threaded Plug 5273979 Compatibility with Cummins Engines

The Cummins-manufactured Threaded Plug part number 5273979 is designed to fit seamlessly into various Cummins engine models. This part is integral for maintaining the integrity and functionality of the engine’s systems. Here is a detailed look at its compatibility across different engine types:

-

4B3.9 and 6B5.9 Engines: The 5273979 threaded plug is compatible with both the 4B3.9 and 6B5.9 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The threaded plug ensures that the engine’s fluid systems remain sealed and operational, preventing leaks and maintaining pressure.

-

B5.6 CM2670 B152B and B6.7 CM2670 B153B Engines: The threaded plug 5273979 fits perfectly with the B5.6 CM2670 B152B and B6.7 CM2670 B153B engines. These engines are part of the Cummins B Series, which is renowned for its efficiency and power. The plug’s design ensures that the engine’s internal components are protected from contaminants, thereby extending the engine’s lifespan.

-

ISB5.9 CM2880 B140 and ISB5.9 CM2880 B149 Engines: The 5273979 threaded plug is also compatible with the ISB5.9 CM2880 B140 and ISB5.9 CM2880 B149 engines. These engines are part of the Cummins ISB Series, which is widely used in both on-highway and off-highway applications. The threaded plug’s precision fit guarantees that the engine’s fluid systems are maintained without any compromise, ensuring optimal performance and reliability.

Role of Part 5273979 Threaded Plug in Engine Systems

The part 5273979 Threaded Plug is integral to the functionality and maintenance of several key components within engine systems.

In the cooler, the threaded plug ensures that the cooling system remains sealed, preventing any coolant leaks that could lead to engine overheating. It maintains the integrity of the cooling passages, allowing for efficient heat dissipation.

Within the engine oil system, the threaded plug plays a significant role in maintaining the pressure and flow of engine oil. It is often used in oil galleries and passages to seal off areas where oil should not escape, ensuring that the oil circulates properly to lubricate moving parts.

In the engine oil cooler, the threaded plug is used to seal connections and passages. This ensures that the oil cooler operates efficiently by maintaining a consistent flow of oil through the cooling fins, which is essential for dissipating heat from the oil.

The lubricating oil filter head also benefits from the use of the threaded plug. It ensures that the filter head remains sealed, preventing any bypass of unfiltered oil into the engine. This is important for maintaining the cleanliness of the engine oil, which in turn protects engine components from wear and damage.

Overall, the threaded plug is a small but essential component that contributes to the reliable operation of these engine systems by ensuring seals are maintained, pressures are consistent, and flows are controlled.

Conclusion

The Cummins 5273979 Threaded Plug is a critical component in the maintenance and operation of commercial truck systems. Its role in sealing and protecting various engine components ensures the efficiency, safety, and longevity of the truck’s systems. Proper installation, regular maintenance, and understanding its compatibility with different Cummins engine models are essential for maximizing the benefits of this Cummins part.

-

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Livesey, Andrew. The Repair of Vehicle Bodies. Elevier, 2000.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.