This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

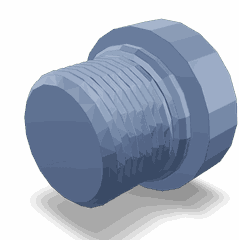

The Cummins 5284000 Threaded Plug is a component designed for use in heavy-duty truck maintenance and operation. It serves a specific function within the truck’s system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is important for maintaining the truck’s performance and longevity.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems. They consist of a threaded body that screws into a corresponding threaded hole, creating a secure seal. In automotive and industrial settings, threaded plugs are employed to prevent leaks, protect internal components from contaminants, and maintain system integrity. They are commonly found in engines, transmissions, and hydraulic systems, among other applications 1.

Purpose of the Cummins 5284000 Threaded Plug

The Cummins 5284000 Threaded Plug plays a role in sealing and protecting various components within a truck’s system. It is specifically designed to fit into designated openings, ensuring that fluids and gases remain contained within their respective systems. By providing a reliable seal, this plug helps maintain the truck’s operational efficiency and prevents potential issues that could arise from leaks or contamination.

Key Features

The Cummins 5284000 Threaded Plug is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The plug features a precise thread type that allows for a secure fit within the corresponding threaded hole. Additionally, its design specifications are tailored to meet the demanding requirements of heavy-duty truck applications, ensuring reliable operation under various conditions 2.

Benefits

Using the Cummins 5284000 Threaded Plug offers several benefits. Its design contributes to improved sealing efficiency, minimizing the risk of leaks and maintaining system integrity. The plug’s resistance to corrosion ensures longevity, even in harsh operating conditions. Furthermore, its durable construction helps withstand the rigors of heavy-duty truck use, providing reliable performance over time.

Installation Process

Proper installation of the Cummins 5284000 Threaded Plug is important to ensure a secure fit and optimal performance. The installation process involves cleaning the threaded hole to remove any debris or contaminants. Using the appropriate tools, the plug is then screwed into the hole until it reaches the desired tightness. It is important to follow manufacturer guidelines to avoid over-tightening, which could damage the plug or the surrounding components 3.

Troubleshooting and Maintenance

Common issues with threaded plugs may include leaks, difficulty in removal, or damage to the threads. Diagnosing problems involves inspecting the plug and the threaded hole for signs of wear, corrosion, or misalignment. Regular maintenance, such as cleaning and inspecting the plug during routine service intervals, can help prolong its lifespan and ensure continued reliable operation.

Safety Considerations

When handling, installing, or maintaining the Cummins 5284000 Threaded Plug, it is important to observe safety guidelines to ensure user safety and component integrity. This includes wearing appropriate personal protective equipment, following manufacturer instructions, and using the correct tools and techniques. Additionally, ensuring that the plug is properly installed and tightened helps prevent accidents and maintains the truck’s operational safety.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history spanning over a century, Cummins is renowned for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range serves various industries, including transportation, construction, and power generation, demonstrating its versatility and expertise in the automotive and industrial sectors.

Threaded Plug 5284000 Compatibility with Cummins Engines

The Threaded Plug 5284000, manufactured by Cummins, is a versatile component designed to fit seamlessly within a range of Cummins engines. This part is engineered to ensure compatibility with the following engine models:

- ISL G CM2180

- ISX12 G CM2180 EJ

- QST30 CM2350 T101

Each of these engines, while distinct in their specifications and applications, shares a commonality in the design and functionality of their components, including the threaded plug. The threaded plug 5284000 is meticulously crafted to meet the stringent requirements of these engines, ensuring optimal performance and reliability. Its design allows for secure and efficient sealing, which is crucial for maintaining the integrity of the engine’s systems.

The compatibility of the threaded plug across these engines underscores its universal design features, making it a reliable choice for maintenance and repair across different engine models. This part’s adaptability highlights Cummins’ commitment to providing high-quality, interchangeable components that enhance engine performance and longevity.

Role of Part 5284000 Threaded Plug in Engine Systems

The part 5284000 Threaded Plug is an essential component in various engine systems, contributing to their efficient operation and maintenance.

In the arrangement of engine components, the threaded plug plays a significant role in sealing and securing connections. It ensures that fluids and gases remain contained within their designated pathways, preventing leaks that could compromise engine performance.

Within the turbocharger system, the threaded plug is used to seal off ports and passages. This sealing is vital for maintaining the turbocharger’s efficiency by ensuring that compressed air is delivered to the engine without any loss of pressure.

The exhaust manifold benefits from the threaded plug by providing a secure seal at various connection points. This helps in maintaining the integrity of the exhaust flow, ensuring that gases are directed efficiently away from the engine.

In the exhaust recirculation cooler kit, the threaded plug is employed to seal the cooler’s inlet and outlet ports. This sealing is important for the proper functioning of the recirculation process, which helps in reducing nitrogen oxide emissions by cooling the recirculated exhaust gases before they are reintroduced into the combustion process.

The manifold system, whether intake or exhaust, utilizes the threaded plug to ensure that all connections are airtight. This is essential for optimal engine performance, as any leaks in the manifold can lead to inefficient air-fuel mixture and reduced power output.

In the exhaust system, the threaded plug is used to seal various joints and connections. This ensures that the exhaust gases are directed through the system without any escape, which is important for both performance and emissions control.

The recirculation system, which is part of the exhaust gas recirculation (EGR) process, relies on the threaded plug to maintain the integrity of the recirculation path. This helps in achieving the desired reduction in emissions by ensuring that the recirculated gases are properly managed.

Lastly, in the broader exhaust system, the threaded plug is crucial for sealing flanges and joints. This ensures that the exhaust system operates efficiently, with minimal loss of exhaust gases, thereby contributing to both performance and emissions standards.

Conclusion

The Cummins 5284000 Threaded Plug is a vital component in the maintenance and operation of heavy-duty trucks. Its role in sealing and protecting various engine systems ensures the efficiency and reliability of the vehicle. With its high-quality construction, precise design, and compatibility across a range of Cummins engines, this part exemplifies Cummins’ commitment to quality and innovation in the automotive and industrial sectors.

-

Hans B. Pacejka, Tyre and Vehicle Dynamics, Butterworth-Heinemann, 2006.

↩ -

SAE International, Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Allan Bonnick and Derek Newbold, A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition, Elsevier Ltd, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.