This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

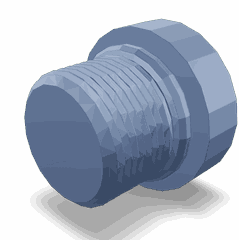

The Cummins 5291831 Threaded Plug is a component designed for use in commercial truck systems. Its primary role is to provide a secure seal in various parts of the truck’s engine and fluid systems, ensuring the integrity and efficiency of these systems.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in pipes, engine blocks, and other equipment. They function by being screwed into a threaded hole, creating a tight seal that prevents fluid or gas leakage. In automotive systems, threaded plugs are commonly used in engine blocks, transmission cases, and fluid reservoirs to maintain system pressure and prevent contamination 1.

Purpose of the Cummins 5291831 Threaded Plug

The Cummins 5291831 Threaded Plug serves a specific role in the operation of a truck by sealing openings in the engine and other fluid systems. This plug helps maintain system pressure, prevent leaks, and protect internal components from contaminants. Its design ensures a reliable seal, contributing to the overall efficiency and longevity of the truck’s systems.

Key Features

The Cummins 5291831 Threaded Plug is constructed from high-quality materials, ensuring durability and resistance to corrosion. It features a specific thread type that matches the requirements of Cummins engines, allowing for a secure fit. The design specifications of this plug enhance its performance, providing a robust seal that can withstand the demanding conditions of commercial truck operations 2.

Benefits

Using the Cummins 5291831 Threaded Plug offers several advantages. It contributes to improved system integrity by providing a reliable seal that prevents leaks and contamination. The plug’s durable construction enhances the longevity of the truck’s systems, reducing the need for frequent replacements. Additionally, its design allows for easy installation, minimizing downtime during maintenance procedures.

Installation Process

Installing the Cummins 5291831 Threaded Plug requires careful attention to ensure a proper seal. Begin by cleaning the threaded hole to remove any debris or old sealant. Apply a compatible thread sealant to the plug’s threads to enhance the seal. Using a torque wrench, screw the plug into the hole until it reaches the specified torque setting, ensuring a secure fit without over-tightening 3.

Troubleshooting Common Issues

Common issues with threaded plugs include leaks and improper sealing. If a leak is detected, first ensure the plug is properly installed and tightened to the correct torque specification. If the problem persists, inspect the plug and the threaded hole for damage or corrosion. In some cases, replacing the plug or repairing the thread may be necessary to achieve a proper seal.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 5291831 Threaded Plug, regular inspections are recommended. Check for signs of wear, corrosion, or damage during routine maintenance checks. If the plug shows signs of deterioration, consider replacing it to prevent potential leaks or system failures. Following the manufacturer’s guidelines for torque settings and installation procedures will also contribute to the plug’s durability.

Compatibility and Usage

The Cummins 5291831 Threaded Plug is designed for use in specific applications within commercial truck fleets. It is compatible with certain Cummins engine models and fluid systems, providing a reliable seal in these applications. Understanding the plug’s compatibility ensures it is used in the correct systems, maintaining the efficiency and safety of the truck’s operations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is evident in its product line, including the Cummins 5291831 Threaded Plug, which is designed to meet the demanding requirements of commercial truck applications.

Threaded Plug 5291831 Compatibility with Cummins Engines

The Threaded Plug 5291831, manufactured by Cummins, is a crucial component designed to fit a variety of Cummins engines. This part is integral to ensuring the integrity and functionality of the engine’s systems. Below is a detailed breakdown of the engines with which this threaded plug is compatible:

B4.5 Series

- B4.5 CM2350 B129B

- ISB4.5 CM2350 B104

D4.0 Series

- D4.0 CM2620 D103B

F3.8 Series

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

- QSF3.8 CM2350 F107

F4.5 Series

- F3.8 F102

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

ISF3.8 Series

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

X12 Series

- X12 CM2670 X121B

X13 Series

- X13 CM2670 X122B

QSF3.8 Series

- QSF3.8 CM2350 F107

- QSF3.8 CM2880 F112

This threaded plug is designed to be versatile, fitting into various engine configurations within the specified series. Its compatibility across multiple engine models underscores its importance in maintaining the operational efficiency and reliability of Cummins engines.

Understanding the Role of Part 5291831 Threaded Plug in Engine Systems

Part 5291831 Threaded Plug is an essential component in various engine systems, serving multiple functions that contribute to the overall efficiency and reliability of the engine. Here’s how it integrates with different components:

Water Inlet and Cooler Systems

In water inlet and cooler systems, the Threaded Plug is often used to seal off unused ports or passages. This ensures that water flows correctly through the system without leaks, maintaining the integrity of the cooling process. It plays a significant role in preventing water ingress into areas where it could cause damage or reduce efficiency.

Engine Oil and Lubricating Oil Cooler Modules

Within engine oil and lubricating oil cooler modules, the Threaded Plug is utilized to block off specific pathways that are not in use. This helps in directing the flow of oil through the cooler more effectively, ensuring that the oil is adequately cooled before it circulates back into the engine. Proper cooling of engine oil is vital for reducing wear and maintaining optimal engine performance.

Oil Cooler and Oil Cooler Housing

In oil cooler and oil cooler housing assemblies, the Threaded Plug is employed to seal off sections of the housing that are not required for the current configuration. This prevents contaminants from entering the system and ensures that the oil cooler operates within its designed parameters. The plug’s sealing capability is key to maintaining the purity and temperature of the oil.

Plumbing and Water Inlet Connection

When it comes to the plumbing and water inlet connection, the Threaded Plug is crucial for maintaining the system’s pressure and flow dynamics. By sealing off unnecessary connections, it helps in directing the water flow to the areas where it is needed most, thus enhancing the cooling efficiency of the engine.

In summary, Part 5291831 Threaded Plug is a versatile component that enhances the functionality and reliability of various engine systems by ensuring proper flow management and sealing integrity.

Conclusion

The Cummins 5291831 Threaded Plug is a vital component in the maintenance and operation of commercial truck engines. Its role in sealing various parts of the engine and fluid systems ensures the integrity and efficiency of these systems. By understanding its features, benefits, and proper installation procedures, users can maximize the performance and longevity of their truck’s systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.