This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5297682 Threaded Insert is a specialized component designed for use in heavy-duty truck applications. Its purpose is to provide a secure and durable connection point for various truck components, ensuring reliable performance under demanding conditions. This part plays a role in maintaining the structural integrity and functionality of heavy-duty trucks, contributing to their overall efficiency and longevity.

Basic Concepts of Threaded Inserts

Threaded inserts are mechanical fasteners used to create strong, permanent threads in materials that might otherwise strip or wear out quickly. They are commonly employed in automotive and industrial settings to enhance the durability and reliability of connections 1. By providing a robust threading solution, these inserts help prevent damage to the base material and ensure that components remain securely fastened, even under high stress or frequent use.

Purpose of the Cummins 5297682 Threaded Insert

The Cummins 5297682 Threaded Insert is specifically designed to enhance the structural integrity and functionality of various components in heavy-duty trucks. It plays a role in ensuring that connections remain secure and durable, even under the extreme conditions often encountered in heavy-duty applications. By providing a reliable threading solution, this insert helps maintain the performance and safety of critical truck components.

Key Features

The Cummins 5297682 Threaded Insert boasts several key features that set it apart from other threaded inserts. It is constructed from high-quality materials, ensuring durability and resistance to wear 2. The design specifications of this insert include precise threading and a robust structure, which contribute to its reliable performance. Additionally, it may feature unique attributes such as corrosion resistance or enhanced load-bearing capabilities, making it well-suited for heavy-duty applications.

Benefits

Using the Cummins 5297682 Threaded Insert offers several benefits, including improved durability, enhanced performance, and potential cost savings over time. Its high-quality construction ensures long-lasting reliability, reducing the need for frequent replacements. The insert’s precise threading and robust design contribute to secure and durable connections, enhancing the overall performance of heavy-duty trucks. Additionally, by providing a reliable solution for threading, it can help prevent damage to components, leading to lower maintenance costs and increased uptime 3.

Installation Process

Proper installation of the Cummins 5297682 Threaded Insert is crucial for ensuring optimal performance and longevity. The process involves several steps, including preparing the installation site, using the appropriate tools to insert the component, and verifying that it is securely fastened. Best practices for installation include ensuring that the base material is clean and free of debris, using the correct torque specifications to avoid over-tightening, and inspecting the insert for proper alignment and seating. Following these guidelines will help ensure that the insert functions as intended and provides the expected benefits.

Troubleshooting and Maintenance

Common issues that may arise with threaded inserts include stripping, loosening, or corrosion. To troubleshoot these problems, it is important to inspect the insert and surrounding components for signs of wear or damage. Regular maintenance practices, such as periodic inspection and cleaning, can help prolong the life of the Cummins 5297682 Threaded Insert. If issues are detected, it may be necessary to replace the insert to ensure continued reliable performance. Adhering to manufacturer recommendations for maintenance and inspection will help maintain the integrity of the insert and the components it supports.

Manufacturer: Cummins

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry. The company is known for its commitment to quality and innovation in manufacturing truck components. With a history of producing reliable and high-performance parts, Cummins has established itself as a trusted name in the industry. Their dedication to excellence is evident in the design and construction of components like the Cummins 5297682 Threaded Insert, which reflects their ongoing commitment to providing durable and efficient solutions for heavy-duty applications.

Threaded Insert 5297682 Compatibility with Cummins Engines

The Cummins Threaded Insert part number 5297682 is designed to fit seamlessly within a variety of Cummins engines, ensuring robust and reliable performance. This part is integral to the assembly and maintenance of these engines, providing a secure connection where threaded fasteners are required.

F4.5 CM2620 F139B

The F4.5 CM2620 F139B engine benefits from the threaded insert 5297682, which is crucial for maintaining the integrity of the engine’s structural components. This part ensures that screws and bolts can be securely fastened without the risk of stripping or loosening over time.

ISF3.8 CM2220 Series

For the ISF3.8 CM2220 engines, which include both the AN and F103 variants, the threaded insert 5297682 plays a vital role in the assembly process. This part is used in areas where high-strength threaded connections are necessary to withstand the stresses of engine operation.

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

QSF2.8 CM2880 Series

The QSF2.8 CM2880 engines, which include the F105 and F114 variants, also utilize the threaded insert 5297682. This part is essential for ensuring that threaded fasteners can be reliably installed in the engine’s components, providing a secure and durable connection.

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

By using the threaded insert 5297682, technicians and engineers can ensure that the engines maintain their structural integrity and operational efficiency. This part is a critical component in the assembly and maintenance of these Cummins engines, providing a reliable solution for threaded connections.

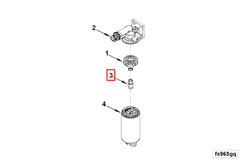

Role of Part 5297682 Threaded Insert in Engine Systems

The 5297682 Threaded Insert is an integral component in the assembly and functionality of several engine systems, particularly those involving fluid management and filtration.

In the fuel filter system, the threaded insert ensures a secure connection between the filter housing and the fuel lines. This connection is essential for maintaining the integrity of the fuel delivery system, preventing leaks, and ensuring consistent fuel flow to the engine.

Within the fuel water separator, the threaded insert plays a similar role. It facilitates a tight seal between the separator housing and the fuel lines, which is vital for the efficient operation of the separator. This component helps in removing water contaminants from the fuel, thereby protecting the engine from potential damage caused by water ingress.

The separator unit, often a part of the fuel system, relies on the threaded insert to maintain a leak-free connection. This is particularly important in high-pressure fuel systems where any leakage can lead to inefficient engine performance or even failure.

Lastly, in the fuel water management system, the threaded insert ensures that the connection between various components remains intact. This is essential for the overall efficiency and reliability of the fuel system, as it prevents any unwanted mixing of fuel and water, which can adversely affect engine operation.

Conclusion

The Cummins 5297682 Threaded Insert is a critical component in the maintenance and operation of heavy-duty trucks and Cummins engines. Its robust design, precise threading, and high-quality construction ensure reliable performance under demanding conditions. Proper installation and maintenance practices are essential for maximizing the benefits of this part, contributing to the overall efficiency and longevity of the vehicles it supports.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.