This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

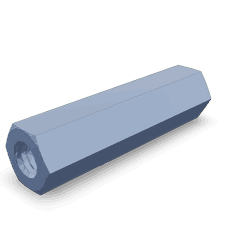

The Cummins 5336282 Threaded Spacer is a specialized component designed for use in heavy-duty truck applications. Its purpose is to provide precise spacing and alignment between various engine components, ensuring optimal performance and longevity. In the context of heavy-duty truck components, this Cummins part plays a significant role by maintaining the correct distance and alignment, which is vital for the efficient operation of the engine and other systems 1.

Basic Concepts of Threaded Spacers

Threaded spacers are mechanical components used to create and maintain specific distances between parts within a system. They function by being screwed into place, providing a stable and adjustable gap. These spacers are commonly utilized in various mechanical systems to ensure proper alignment, reduce vibrations, and prevent component wear. Their applications range from engine assemblies to structural frameworks, making them versatile and essential in many industries 2.

Purpose of the Cummins 5336282 Threaded Spacer

The Cummins 5336282 Threaded Spacer is specifically designed to play a role in the operation of heavy-duty trucks by ensuring the correct spacing between engine components. This precise spacing is crucial for the proper functioning of the engine, as it helps in maintaining alignment, reducing wear, and enhancing overall performance. By integrating this spacer into the engine system, Cummins ensures that the components operate within their designed parameters, leading to improved efficiency and durability 3.

Key Features

The Cummins 5336282 Threaded Spacer boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The thread specifications are designed to provide a secure fit, while the spacer’s design characteristics allow for easy installation and adjustment. These features collectively contribute to the spacer’s ability to maintain precise spacing and alignment over time 4.

Benefits of Using the Cummins 5336282 Threaded Spacer

Utilizing the Cummins 5336282 Threaded Spacer offers several advantages. It improves alignment between engine components, which can lead to enhanced performance and reduced wear. The spacer also contributes to the longevity of associated components by ensuring they operate within their designed parameters. Additionally, the precise spacing provided by the spacer helps in minimizing vibrations, which can further extend the lifespan of the engine and other systems 1.

Installation Considerations

Proper installation of the Cummins 5336282 Threaded Spacer is vital to ensure it functions correctly. Guidelines for installation include using the appropriate tools to avoid damage to the threads. It is also important to follow the manufacturer’s instructions regarding torque specifications to ensure a secure fit. Careful attention to these details during installation will help maintain the spacer’s effectiveness and durability 2.

Troubleshooting Common Issues

Common issues with threaded spacers may include improper alignment, wear, or damage to the threads. To address these problems, it is important to inspect the spacer regularly for signs of wear or damage. If issues are detected, the spacer should be replaced or repaired as necessary. Ensuring that the spacer is correctly installed and maintained can help prevent these common problems 3.

Maintenance Tips

Regular maintenance of the Cummins 5336282 Threaded Spacer is important to ensure optimal performance and longevity. This includes periodic inspection for signs of wear or damage, and cleaning the spacer to remove any debris or contaminants. Following these maintenance tips will help keep the spacer in good condition, ensuring it continues to provide the precise spacing and alignment needed for the efficient operation of the engine and other systems 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industry for producing high-quality, reliable components. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications 1.

Threaded Spacer Part 5336282 in Cummins Engines

The Threaded Spacer part 5336282 is a critical component in several Cummins engine models. This part is essential for maintaining the structural integrity and proper alignment of various engine parts. Here is how it fits into specific Cummins engines:

B4.5 CM2350 B104

In the B4.5 CM2350 B104 engine, the threaded spacer part 5336282 is utilized to ensure that the threaded connections between different engine components are properly spaced and aligned. This helps in maintaining the engine’s overall stability and performance 2.

D4.0 CM2620 D103B and F3.8 CM2620 F137B

For the D4.0 CM2620 D103B and F3.8 CM2620 F137B engines, the threaded spacer part 5336282 serves a similar purpose. It is used in the assembly of engine parts that require precise spacing to function correctly. This includes connections that need to be threaded and secured, ensuring that the engine operates smoothly and efficiently 3.

F4.5 CM2620 F139B

In the F4.5 CM2620 F139B engine, the threaded spacer part 5336282 is integral to the assembly of components that require threaded connections. This part ensures that the engine’s threaded parts are correctly spaced, which is crucial for the engine’s operational integrity 4.

B129B

The B129B engine also utilizes the threaded spacer part 5336282. This part is essential for maintaining the alignment and spacing of threaded connections within the engine, contributing to the engine’s overall performance and durability 1.

By using the threaded spacer part 5336282, Cummins ensures that these engines maintain their structural integrity and operational efficiency. This part is a testament to Cummins’ commitment to quality and precision in engine manufacturing.

Role of Part 5336282 Threaded Spacer in Engine Systems

The 5336282 Threaded Spacer is an essential component in maintaining the structural integrity and proper function of various engine systems. It is particularly significant in the context of the Harness and Electronic Control Module (ECM) Wiring.

Harness Integration

In the assembly of the Harness, the 5336282 Threaded Spacer ensures that wires are correctly spaced and aligned. This spacing is vital for preventing wire chafing and ensuring that the Harness maintains its intended shape and function. The spacer helps in distributing the mechanical stresses evenly across the Harness, which is especially important in high-vibration environments typical of engine compartments 2.

ECM Wiring Configuration

For the ECM Wiring, the 5336282 Threaded Spacer plays a role in maintaining the precise distances between wires and connectors. This is important for the reliable transmission of signals between the ECM and various engine sensors and actuators. Proper spacing ensures that there is no cross-talk between wires, which could lead to erroneous data being sent to or from the ECM. Additionally, it helps in keeping the wiring organized, making it easier to diagnose and service the system when needed 3.

In both applications, the 5336282 Threaded Spacer contributes to the overall reliability and durability of the engine systems by ensuring that components are held in their correct positions and that electrical connections remain secure and unaffected by environmental factors 4.

Conclusion

The Cummins 5336282 Threaded Spacer is a critical component in the maintenance and operation of heavy-duty truck engines. Its role in ensuring precise spacing and alignment between engine components is vital for the efficient and reliable operation of the engine. By understanding the key features, benefits, and proper installation and maintenance of this part, technicians and engineers can ensure the longevity and performance of Cummins engines.

-

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ ↩ ↩ ↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ ↩ ↩ ↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ ↩ ↩ ↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training Theory. Routledge, 2022.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.