This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5338087 Threaded Spacer is a component manufactured by Cummins, a well-established name in the commercial truck industry. This spacer is designed for use in commercial trucks, where it contributes to the efficient operation of various systems. Cummins is renowned for its high-quality parts and comprehensive product range, making the 5338087 Threaded Spacer a reliable choice for truck maintenance and performance enhancement.

Basic Concepts of Threaded Spacers

Threaded spacers are mechanical components used to maintain proper spacing and alignment between parts in a system. They are commonly employed in various mechanical systems to ensure that components are correctly positioned relative to each other. By providing the necessary distance between parts, threaded spacers help to prevent issues such as misalignment, which can lead to decreased performance or damage to the system. They are typically made from durable materials to withstand the stresses and environmental conditions encountered in their applications 1.

Purpose of the 5338087 Threaded Spacer

This Cummins part plays a specific role in the operation of a truck. It is designed to ensure proper spacing and alignment within the engine or other systems, which is vital for the optimal functioning of these components. By maintaining the correct distance between parts, this spacer helps to ensure that the system operates smoothly and efficiently. Its application in commercial trucks underscores the importance of precise component alignment in achieving reliable performance.

Key Features

The 5338087 Threaded Spacer boasts several key features that contribute to its effectiveness. It is constructed from high-quality materials, ensuring durability and resistance to wear. The spacer features a specific thread type that allows for secure attachment to other components, facilitating easy installation and removal when necessary. Its dimensions are carefully designed to provide the exact spacing required for its application, enhancing the performance and reliability of the truck’s systems.

Benefits

Using the 5338087 Threaded Spacer offers several benefits. It contributes to improved performance by ensuring that components are properly aligned and spaced. This precise alignment can lead to enhanced efficiency and reduced wear on the system. The spacer’s durable construction and reliable design also contribute to the overall durability and reliability of the truck, making it a valuable component for maintaining optimal operation.

Installation Process

Installing the 5338087 Threaded Spacer requires careful attention to detail to ensure proper function. The process involves cleaning the installation area to remove any debris or contaminants that could affect performance. The spacer is then positioned between the components it is designed to separate, and secured in place using the appropriate tools. It is important to follow the manufacturer’s guidelines for torque specifications to ensure that the spacer is properly tightened without over-tightening, which could damage the component or the system.

Troubleshooting Common Issues

Common issues with threaded spacers can include misalignment, wear, or damage to the spacer itself. These problems can often be identified through regular inspection and maintenance. If a spacer is found to be misaligned or damaged, it should be replaced to prevent further issues. Ensuring that the spacer is correctly installed and maintained can help to avoid these common problems.

Maintenance Tips

Regular maintenance of the 5338087 Threaded Spacer is important for ensuring its longevity and optimal performance. This includes regular inspection for signs of wear or damage, and replacement if necessary. Keeping the spacer and its installation area clean can also help to prevent issues such as corrosion or contamination, which can affect performance. Following the manufacturer’s guidelines for maintenance and replacement can help to ensure that the spacer continues to function effectively.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s extensive product range and commitment to innovation and customer satisfaction have made it a preferred choice for truck manufacturers and operators worldwide.

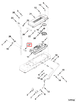

Threaded Spacer Part 5338087 in Cummins Engines

The Threaded Spacer part 5338087, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to ensure proper alignment and spacing between various engine components, contributing to the overall efficiency and longevity of the engine.

B6.7 CM2350

In the B6.7 CM2350 engine, the 5338087 Threaded Spacer plays a vital role in maintaining the structural integrity of the engine. It is typically used in areas where precise spacing is necessary to prevent misalignment, which could lead to increased wear and potential engine failure.

B135B

Similarly, in the B135B engine, the 5338087 Threaded Spacer is essential for ensuring that components are correctly positioned. This part is often utilized in the assembly of the engine block, where it helps to secure various parts in their designated locations, thereby maintaining the engine’s operational efficiency.

Grouping of Engines

Both the B6.7 CM2350 and B135B engines benefit from the use of the 5338087 Threaded Spacer. While these engines may have different specifications and applications, the threaded spacer serves a common purpose across both models. It ensures that the engine components are held together securely and accurately, which is crucial for the smooth operation of the engine.

By using the 5338087 Threaded Spacer, Cummins ensures that these engines can perform reliably under various conditions, maintaining their efficiency and durability over time.

Conclusion

The 5338087 Threaded Spacer is integral to the proper arrangement and function of several engine components. In the context of the crankcase breather plumbing, this threaded spacer ensures that the breather tube is correctly positioned and maintained at the optimal distance from the crankcase. This precise spacing is essential for the efficient operation of the breather system, which is responsible for venting pressure and contaminants from the crankcase.

The breather, an important component in maintaining engine health, relies on the threaded spacer to keep the breather tube aligned and secure. This alignment prevents any potential leaks or misalignments that could disrupt the breather’s function. The crankcase, which houses the engine’s moving parts, benefits from the stable and consistent pressure management provided by the properly spaced breather tube.

In summary, the 5338087 Threaded Spacer plays a significant role in the effective integration and operation of the crankcase breather plumbing, breather, and crankcase components within the engine system.

-

Richard Stone, Introduction to Internal Combustion Engines, Fourth Edition, Macmillan, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.