3089567

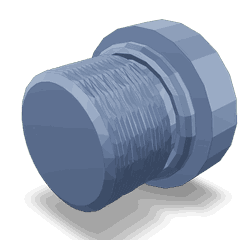

Threaded Plug

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Threaded Plug 3089567 is a component designed for use in commercial truck operations. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems, such as engines, fuel systems, and hydraulic systems. They function by creating a secure, leak-proof seal when screwed into place. Their applications range from preventing fluid leaks to protecting sensitive components from contaminants. In automotive components, threaded plugs are vital for maintaining system integrity and ensuring optimal performance 1.

Purpose of Cummins Threaded Plug 3089567

The Cummins Threaded Plug 3089567 is specifically designed to seal openings within the truck’s engine or other systems. Its primary role is to prevent fluid leaks and protect internal components from external contaminants. By ensuring a tight seal, it contributes to the efficient operation of the engine and helps maintain system pressure and performance 4.

Key Features

The Cummins Threaded Plug 3089567 is constructed from high-quality materials, ensuring durability and resistance to wear. Its threading specifications are designed to provide a secure fit, minimizing the risk of leaks. The plug’s design characteristics, including its shape and size, are tailored to meet the specific requirements of Cummins engines, enhancing its performance and longevity 2.

Benefits

Using the Cummins Threaded Plug 3089567 offers several advantages. It improves system integrity by providing a reliable seal, preventing fluid leaks that could lead to engine damage or decreased performance. Additionally, it contributes to overall engine efficiency by maintaining system pressure and protecting internal components from contaminants 3.

Installation Process

Proper installation of the Cummins Threaded Plug 3089567 is crucial for its effective performance. The process involves cleaning the installation site to remove any debris, applying a thread sealant if recommended, and screwing the plug into place using the appropriate tools. It is important to follow manufacturer guidelines to ensure a secure fit and optimal performance 4.

Troubleshooting Common Issues

Common issues with threaded plugs include leaks and difficulty in removal. Leaks may occur due to improper installation, damage to the plug, or wear over time. Troubleshooting steps include inspecting the plug for damage, ensuring it is properly installed, and replacing it if necessary. Difficulty in removal may require the use of specialized tools or techniques to avoid damaging the plug or surrounding components 4.

Maintenance Tips

Regular maintenance of the Cummins Threaded Plug 3089567 is important for its longevity and reliable performance. This includes periodic inspection for signs of wear or damage, ensuring it remains securely installed, and replacing it according to manufacturer guidelines or when signs of deterioration are observed. Adhering to these practices helps maintain system integrity and engine efficiency 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Compatibility with Cummins Engines

The threaded plug part number 3089567, manufactured by Cummins, is designed to fit a variety of Cummins engines. This plug is commonly used in applications where a threaded connection is required, such as for oil or coolant lines. Here is a breakdown of the engines with which this part is compatible:

B4.5 and B6.7 Series Engines

- B4.5 CM2350 B129B

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

- B6.7S

B5.9 Series Engines

- B5.9 G

- B5.9 GAS PLUS CM556

F3.8 and F4.5 Series Engines

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

C8.3 Series Engine

- C8.3 G

D4.0 Series Engine

- D4.0 CM2620 D103B

ISB Series Engines

- ISB (Chrysler)

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB4.5 CM2350 B104

- ISB5.9 CM2880 B110

This threaded plug is engineered to ensure a secure and leak-proof connection, making it a critical component in maintaining the integrity of the engine’s fluid systems.

Role of Part 3089567 Threaded Plug in Engine Systems

The Part 3089567 Threaded Plug is integral to maintaining the integrity and efficiency of various engine systems. It is strategically employed in several components to ensure optimal performance and prevent leaks.

Air Assembly Cleaner

In the air assembly cleaner, the threaded plug secures the connection points, ensuring that the air intake system remains sealed. This prevents any unfiltered air from entering the system, which could otherwise compromise engine performance.

Alternator Mounting

For the alternator mounting, the threaded plug is used to seal off any unnecessary openings. This helps in maintaining a stable and secure mounting for the alternator, ensuring consistent power generation.

Engine Oil Cooler and Torque Converter Oil Cooler

In both the engine oil cooler and torque converter oil cooler, the threaded plug plays a significant role in sealing the cooler passages. This ensures that the cooling fluid circulates efficiently without any leaks, maintaining the optimal temperature of the engine oil and torque converter oil.

Crankcase Breather Mounting

The crankcase breather mounting utilizes the threaded plug to seal the breather system. This prevents any contaminants from entering the crankcase while allowing pressure to be released, maintaining a balanced environment within the engine.

Exhaust Assembly Manifold

In the exhaust assembly manifold, the threaded plug is used to seal off any unused ports. This ensures that the exhaust flow remains directed and efficient, reducing the risk of backpressure and improving overall engine performance.

Full Flow Oil Filter and Lubricating Oil Filter

For the full flow oil filter and lubricating oil filter, the threaded plug is employed to seal the filter housing. This ensures that the oil filtration process is effective, preventing any bypass of contaminants and maintaining clean oil circulation.

Fuel Pump Adapter and Gear Fuel Pump

In the fuel pump adapter and gear fuel pump, the threaded plug seals the fuel passages. This ensures that the fuel delivery system remains pressurized and leak-free, contributing to consistent fuel supply and engine operation.

Lubricating Oil Module Assembly and Lubricating Oil Pressure Assembly

The threaded plug is vital in the lubricating oil module assembly and lubricating oil pressure assembly for sealing various components. This ensures that the lubrication system operates under the correct pressure, providing adequate lubrication to engine parts and reducing wear.

Auxiliary Cooling, Cabin Heater, and Engine Coolant Plumbing

In the auxiliary cooling, cabin heater, and engine coolant plumbing systems, the threaded plug seals the connections and passages. This ensures efficient coolant flow, maintaining the desired temperature for both the engine and the cabin.

Turbocharger

In the turbocharger, the threaded plug is used to seal various inlets and outlets. This ensures that the turbocharger operates efficiently without any leaks, contributing to improved engine performance and boost pressure.

Fuel System Primer

For the fuel system primer, the threaded plug seals the priming system, ensuring that the fuel lines are properly pressurized before engine start-up. This facilitates easier starting and consistent fuel delivery.

Thermostat (Top Level Assembly) Housing

In the thermostat (top level assembly) housing, the threaded plug seals the thermostat housing. This ensures that the coolant flow is regulated effectively, maintaining the engine at the optimal operating temperature.

Conclusion

The Cummins Threaded Plug 3089567 plays a crucial role in maintaining the integrity and efficiency of various engine systems. Its proper installation, maintenance, and understanding of its role are essential for ensuring optimal engine performance and reliability.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ ↩ ↩ ↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 3679139 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.