This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Threaded Plug 3678922 is a specialized component designed for use in commercial trucks. It plays a role in maintaining the integrity and efficiency of the truck’s systems. Understanding its purpose and functionality is key to ensuring proper maintenance and operation of commercial vehicles.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems, including automotive and industrial applications. They function by creating a secure, leak-proof seal when screwed into place. These plugs are important in preventing fluid or gas leaks, maintaining system pressure, and protecting internal components from contaminants 1.

Purpose of Cummins Threaded Plug 3678922

The Cummins Threaded Plug 3678922 is specifically designed to seal openings in truck systems, playing a role in maintaining system pressure and preventing leaks. Its application ensures the integrity of the system it is installed in, contributing to the overall efficiency and reliability of the truck.

Key Features

The Cummins Threaded Plug 3678922 is constructed with high-quality materials, ensuring durability and resistance to wear. It features a specific thread type that allows for a secure fit in designated openings. The design specifications of this plug are tailored to meet the demanding conditions of commercial truck operations, enhancing its performance and longevity 2.

Benefits of Using Cummins Threaded Plug 3678922

Utilizing the Cummins Threaded Plug 3678922 offers several advantages. It contributes to improved system reliability by providing a secure seal. The design of the plug facilitates ease of installation, reducing downtime during maintenance procedures. Additionally, its durability leads to long-term cost savings by minimizing the need for frequent replacements 3.

Installation Process

Installing the Cummins Threaded Plug 3678922 requires following a series of steps to ensure a proper fit and seal. Begin by cleaning the installation site to remove any debris or old sealant. Carefully thread the plug into the opening, ensuring it is snug but not overtightened to avoid damage. Verify the seal by checking for leaks after installation.

Troubleshooting Common Issues

Common issues with threaded plugs include leaks or improper sealing. These problems can often be traced back to incorrect installation or wear and tear on the plug. Troubleshooting involves inspecting the plug and its seating for damage, ensuring the threads are clean and undamaged, and verifying that the plug is correctly installed.

Maintenance Tips

Regular maintenance of the Cummins Threaded Plug 3678922 is important for ensuring its optimal performance and longevity. This includes periodic inspections for signs of wear or damage, cleaning the threads and seating area, and replacing the plug if it shows signs of deterioration. Adhering to these maintenance practices helps prevent system failures and extends the life of the plug.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality components. With a rich history of innovation and reliability, Cummins products are trusted by professionals worldwide. The company’s commitment to quality and performance is evident in each component it produces, including the Cummins Threaded Plug 3678922.

Threaded Plug 3678922 Compatibility with Cummins Engines

The Threaded Plug 3678922, manufactured by Cummins, is designed to fit a variety of Cummins engines. This plug is essential for sealing and securing various components within the engine system. Below is a detailed description of its compatibility with specific Cummins engines:

B Series Engines

- B4.5 RGT

- B5.6 CM2670 B152B

- B5.9 GAS PLUS CM556

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

- B6.7S

G Series Engines

- G5.9

- G5.9 CM558

- G8.3

- G8.3 CM558

F Series Engines

- F2.8 CM2620 F135B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F3.8 F102

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

Other Series Engines

- 15N CM2380 M104B

- 6B5.9

- 6C8.3

- GTA38 G CMEICS G116C

- GTA8.3 CM558

This threaded plug is engineered to ensure a secure fit and reliable performance across these engine models, facilitating proper sealing and preventing leaks. It is important to verify the specific application of the plug within the engine to ensure compatibility and optimal performance.

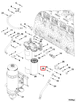

Role of Part 3678922 Threaded Plug in Engine Systems

The part 3678922 Threaded Plug is integral to the functionality and efficiency of various engine systems. It is utilized in several components to ensure proper sealing, pressure maintenance, and fluid management.

In the Accessory Drive Support, the threaded plug secures components and prevents fluid leaks, ensuring the smooth operation of driven accessories.

The Adapter Cross uses the threaded plug to maintain pressure integrity within the system, which is essential for the efficient transfer of fluids or gases.

Within the Aftercooler and Air Manifold Assembly, the threaded plug helps in sealing connections, ensuring optimal cooling and air distribution to the engine.

In the Assembly Aftercooler, it plays a role in maintaining the structural integrity and sealing of the aftercooler, contributing to effective air cooling before it enters the engine.

The Auxiliary Cooling Inlet Connection relies on the threaded plug to ensure a secure and leak-free connection, vital for the auxiliary cooling system’s performance.

For the Cover Plate, the threaded plug is used to seal openings, protecting internal components from contaminants and ensuring system pressure is maintained.

In the Engine Installation Kit, it is employed to seal various connections during the engine installation process, ensuring a secure and leak-free setup.

The Engine Lubricating Primer uses the threaded plug to seal priming ports, ensuring the lubricant is effectively distributed throughout the engine.

In the Exhaust Gas Recirculation Mixer Ejector, it helps in sealing connections, ensuring the recirculated exhaust gas is efficiently mixed with the intake air.

The Filter component utilizes the threaded plug to seal filter housings, preventing contaminants from bypassing the filtration system.

For the Fuel Pump Oil and Fuel Flow Valve, the threaded plug ensures secure connections and sealing, critical for the precise delivery of fuel to the engine.

In the Gear Assembly Housing, it is used to seal various ports and passages, ensuring the gear assembly operates within a controlled environment.

The Long Block incorporates the threaded plug to seal openings and passages, maintaining the integrity of the engine block.

In the Marine Gear Oil Cooler, it ensures secure connections and sealing, vital for the efficient cooling of marine gear oil.

The Oil Filter Cooler Head and Oil Filter Head Plumbing use the threaded plug to seal connections, ensuring the oil filtration and cooling process is effective.

For the Oil Pan Plumbing and Oil Pan Top Level Assembly Adapter, it ensures secure and leak-free connections, maintaining the oil level and pressure within the system.

In the Raw Water Inlet Connection and Raw Water Outlet Connection, the threaded plug is essential for sealing these critical points, ensuring the raw water system operates efficiently.

The Thermostat Housing Plumbing relies on the threaded plug to seal connections, ensuring the thermostat housing functions correctly in regulating engine temperature.

In the Turbocharger Plumbing, it is used to seal various connections, ensuring the turbocharger system operates efficiently and without leaks.

The Upfit Kit incorporates the threaded plug to seal additional components and connections, ensuring the upfit system is secure and functional.

Finally, in the Water Pump Arrangement, the threaded plug is used to seal connections, ensuring the water pump operates efficiently and without leaks.

Conclusion

The Cummins Threaded Plug 3678922 is a critical component in the maintenance and operation of commercial trucks. Its role in sealing various engine systems ensures the efficiency, reliability, and longevity of the truck’s components. Proper installation, maintenance, and understanding of its compatibility with Cummins engines are essential for optimal performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.