This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

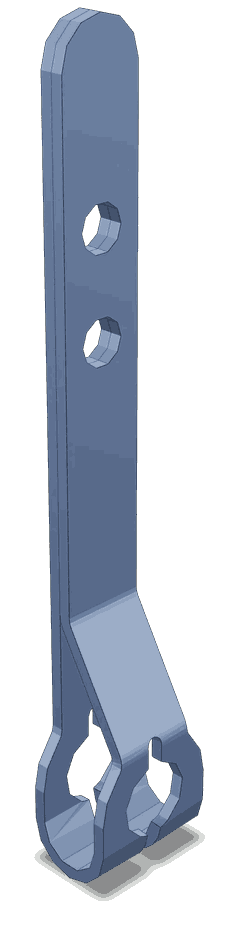

The Cummins 101645 Throttle Lever is a component designed for use in commercial trucks equipped with Cummins engines. Its purpose is to provide a means for the driver to control the engine’s speed and power output, which is essential for the efficient operation of the vehicle. By modulating the throttle, drivers can adjust the engine’s performance to suit various driving conditions and load requirements.

Basic Concepts of Throttle Levers

A throttle lever is a mechanical or electronic device used in engine systems to regulate the amount of fuel and air entering the engine. This control directly influences the engine’s speed and power output. In traditional mechanical systems, the throttle lever is connected to the carburetor or fuel injection system via a cable or linkage. In modern electronic systems, the throttle lever sends signals to the engine control unit (ECU), which then adjusts the fuel delivery and ignition timing accordingly 1. The significance of the throttle lever lies in its ability to allow the driver precise control over the engine’s performance, ensuring optimal operation under varying conditions.

Purpose and Role of the Cummins 101645 Throttle Lever

The Cummins 101645 Throttle Lever plays a specific role in the operation of a truck by interfacing with the engine control system to modulate fuel delivery and engine performance. When the driver moves the throttle lever, it sends a signal to the ECU, which adjusts the fuel injection rate and timing to match the desired engine speed and load 2. This interaction allows for smooth acceleration, deceleration, and maintenance of cruising speeds, contributing to the overall drivability and efficiency of the truck.

Key Features

The Cummins 101645 Throttle Lever is characterized by its robust design and the use of high-quality materials, ensuring durability and reliability in demanding commercial truck applications. Its design includes a precise mechanism for accurate throttle position sensing, which is crucial for the ECU to make the correct adjustments to the engine’s operation. Additionally, the lever is ergonomically designed for ease of use, reducing driver fatigue during long hours of operation.

Benefits of Using the Cummins 101645 Throttle Lever

Utilizing the Cummins 101645 Throttle Lever offers several advantages. It provides improved engine control, allowing for more precise modulation of engine speed and power. This can lead to enhanced driver comfort, as the truck responds more smoothly to throttle inputs. Furthermore, optimal engine control can contribute to potential increases in fuel efficiency and overall performance, making it a valuable component for fleet operators looking to maximize their vehicles’ efficiency and productivity 3.

Installation and Integration

Proper installation and integration of the Cummins 101645 Throttle Lever within a truck’s engine system are crucial for ensuring its effective operation. Installation typically involves connecting the lever to the existing throttle linkage or electronic control system, following the manufacturer’s guidelines to ensure compatibility and proper function. Adjustments may be necessary to calibrate the throttle response to the specific engine and driving conditions, ensuring that the lever operates within the desired range of motion and sensitivity.

Troubleshooting and Maintenance

To maintain the Cummins 101645 Throttle Lever’s longevity and optimal performance, regular maintenance is recommended. This includes checking for any signs of wear or damage to the lever and its connections, ensuring that all linkages are secure and free from obstruction. Troubleshooting common issues may involve adjusting the throttle position sensor or checking the electronic connections for proper signal transmission. Signs of wear or failure, such as inconsistent engine performance or difficulty in modulating throttle, may indicate the need for replacement or repair.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines for on-highway and off-highway applications, as well as components and systems designed to enhance vehicle performance and efficiency. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice among fleet operators and vehicle manufacturers worldwide.

Cummins Throttle Lever (Part 101645) Compatibility

The Cummins Throttle Lever, identified by the part number 101645, is a critical component designed to manage the engine’s power output by controlling the throttle. This part is engineered to ensure smooth and precise operation, enhancing the overall performance and reliability of the engine systems it is integrated with.

K19 Engine Series

The K19 engine series is one of the platforms where the Throttle Lever 101645 is utilized. This series is known for its robust design and efficiency, making it suitable for various industrial and commercial applications. The Throttle Lever in this context plays a pivotal role in maintaining the engine’s operational integrity by providing a direct link between the operator’s commands and the engine’s throttle mechanism.

The compatibility of the Throttle Lever 101645 with the K19 engine series ensures that users can expect consistent performance and ease of use. This part is designed to fit seamlessly into the engine’s architecture, allowing for straightforward installation and operation. The precision engineering of the Throttle Lever ensures that it can withstand the rigors of continuous use in demanding environments, contributing to the longevity and dependability of the K19 engines.

Role of Part 101645 Throttle Lever in Engine Systems

The Throttle Lever, identified as part 101645, is an integral component in the orchestration of engine performance. It is meticulously designed to modulate the airflow into the engine, thereby directly influencing the power output and efficiency of the engine system.

When the Throttle Lever is actuated, it adjusts the position of the throttle plate within the throttle body. This action controls the volume of air that is allowed to pass through to the engine’s intake manifold. The precise regulation of airflow is essential for maintaining the correct air-fuel mixture, which is vital for optimal combustion.

In conjunction with the Fuel Pump, the Throttle Lever ensures that the engine receives the appropriate amount of fuel corresponding to the airflow. The Fuel Pump delivers fuel from the tank to the engine, and its operation is often synchronized with the throttle position to maintain the desired air-fuel ratio.

The interaction between the Throttle Lever and other components such as the Throttle Position Sensor (TPS) and the Engine Control Unit (ECU) is also significant. The TPS monitors the position of the throttle and sends this data to the ECU, which then adjusts the fuel delivery and ignition timing accordingly.

Moreover, the Throttle Lever is often linked to the accelerator pedal through a series of mechanical or electronic connections. This linkage ensures that the driver’s input is accurately translated into engine response, providing a seamless driving experience.

Conclusion

In summary, the Cummins 101645 Throttle Lever is a pivotal element in the engine’s control system, working in harmony with the Fuel Pump and other related components to deliver a responsive and efficient engine performance. Its robust design, precise operation, and compatibility with the K19 engine series make it an indispensable part for operators seeking to maintain optimal engine operation.

-

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.