This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3003310 Throttle Lever is a component designed for use in commercial trucks. It plays a role in the operation of these vehicles by allowing the driver to control the engine’s speed and power output. This part is integral to the efficient and safe operation of the truck, ensuring that the engine performs optimally under various driving conditions.

Basic Concepts of Throttle Levers

A throttle lever is a mechanical device that modulates the amount of fuel and air entering an engine, thereby controlling its speed and power output. Within an engine system, the throttle lever is connected to the throttle body or carburetor, which regulates the airflow into the engine. By adjusting the position of the throttle lever, the driver can increase or decrease the engine’s RPM, which in turn affects the vehicle’s acceleration and cruising speed 1.

Purpose of the 3003310 Throttle Lever

The Cummins 3003310 Throttle Lever is specifically designed to interface with the engine control system of commercial trucks. Its role is to provide precise modulation of engine performance, allowing the driver to adjust the throttle setting according to the load, terrain, and driving conditions. This part ensures that the engine operates within its optimal range, enhancing both performance and fuel efficiency.

Key Features

The Cummins 3003310 Throttle Lever is characterized by its robust design and high-quality materials. It is engineered to withstand the rigors of commercial truck operation, featuring a durable construction that ensures longevity and reliability. The lever’s ergonomic design enhances the driver’s control and comfort, while its precise calibration allows for accurate throttle adjustments.

Benefits of Using the 3003310 Throttle Lever

Utilizing the Cummins 3003310 Throttle Lever offers several advantages. It provides improved engine control, allowing for more precise adjustments to engine speed and power. This can lead to an enhanced driver experience, as the lever’s smooth operation and responsive design make it easier to manage the truck’s performance. Additionally, the lever’s design contributes to potential increases in fuel efficiency and overall engine performance, making it a valuable component for commercial truck operators 2.

Installation and Integration

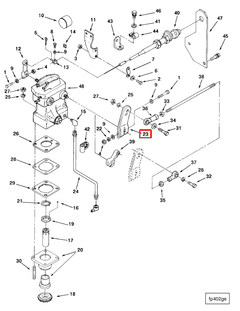

Proper installation of the Cummins 3003310 Throttle Lever is crucial for ensuring optimal performance. The installation process involves connecting the lever to the engine’s throttle body or carburetor and securing it in place. It may also require adjustments or calibrations to align the lever with the engine control system, ensuring that throttle adjustments are accurately reflected in engine performance.

Troubleshooting Common Issues

Common issues with the Cummins 3003310 Throttle Lever may include unresponsiveness, difficulty in adjusting the throttle, or unusual noises during operation. Diagnostic steps to address these problems may involve checking the lever’s connection to the throttle body, inspecting for wear or damage, and ensuring that the lever is properly calibrated. Solutions may range from simple adjustments to replacement of worn components.

Maintenance Tips

Routine maintenance of the Cummins 3003310 Throttle Lever is important for prolonging its lifespan and ensuring reliable operation. Maintenance practices should include regular cleaning to remove dirt and debris, lubrication of moving parts to reduce friction, and periodic inspection for signs of wear or damage. Following these maintenance tips can help prevent issues and ensure the lever continues to function effectively.

Safety Considerations

When working with the Cummins 3003310 Throttle Lever, it is important to observe safety protocols to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, ensuring the truck is parked on a level surface before beginning any work, and following all manufacturer guidelines for installation, maintenance, and troubleshooting. Adhering to these safety considerations helps protect both the technician and the vehicle.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial vehicle operators 3.

Throttle Lever Compatibility with Cummins Engines

The Cummins part number 3003310, a Throttle Lever, is designed to fit seamlessly with several of Cummins’ engine models. This throttle lever is a critical component that ensures smooth and precise control over the engine’s power output. Below is a detailed look at how this part integrates with various Cummins engines.

K19, K38, K50 Engines

The K19, K38, and K50 engines are part of Cummins’ K Series line, known for their robust design and reliability. The throttle lever 3003310 is engineered to fit these engines perfectly, providing a reliable means of controlling the engine’s throttle. This compatibility ensures that operators can maintain consistent engine performance and responsiveness, crucial for various applications ranging from construction to transportation.

N14 MECHANICAL Engine

The N14 MECHANICAL engine is another robust model in Cummins’ lineup, often used in heavy-duty applications. The throttle lever 3003310 is specifically designed to interface with the N14 MECHANICAL engine, ensuring that the throttle control mechanism operates smoothly and efficiently. This compatibility is essential for maintaining the engine’s performance and longevity in demanding environments.

NH/NT 855 Engines

The NH/NT 855 engines are part of Cummins’ NT Series, designed for agricultural and construction machinery. The throttle lever 3003310 is engineered to fit these engines, providing precise control over the engine’s throttle. This ensures that the engine can deliver the necessary power and efficiency required for these demanding applications.

V28 Engine

The V28 engine is a high-performance model in Cummins’ lineup, often used in marine and industrial applications. The throttle lever 3003310 is designed to fit the V28 engine, ensuring that the throttle control mechanism operates smoothly and efficiently. This compatibility is crucial for maintaining the engine’s performance and reliability in various demanding environments.

By ensuring that the throttle lever 3003310 fits seamlessly with these engines, Cummins maintains a high standard of quality and reliability, providing operators with the confidence that their engines will perform optimally under any conditions.

Role of Part 3003310 Throttle Lever in Engine Systems

The 3003310 Throttle Lever is an integral component in the orchestration of various engine systems, ensuring precise control and efficient operation. When integrated with the American Bosch Governor or the Barber-Colman Governor, the throttle lever facilitates smooth transitions in engine speed by modulating the fuel supply in response to load changes.

In conjunction with the Coupling and Fuel Pump, the throttle lever ensures that the engine receives the appropriate amount of fuel at any given moment, optimizing performance and fuel efficiency. The interaction with the Fuel Pump & Drive (Wood) and Fuel Pump Woodward systems further enhances this precision, allowing for fine-tuned adjustments that cater to varying operational demands.

When paired with Governor and Drive units or Hydraulic Governors, the throttle lever plays a significant role in maintaining consistent engine speed under fluctuating loads. This is particularly important in systems utilizing Electronic Governors or Fuel Woodward Pumps, where the throttle lever’s adjustments are critical for maintaining optimal engine performance.

In setups involving Non-AFC Auto FP/Gov. Sump or Non-AFC VS FP/Gov. Sump, the throttle lever ensures that the fuel delivery is calibrated to match the engine’s requirements, preventing issues such as overfueling or underfueling. Similarly, with Woodward 2301 Governor or Woodward PSG Governor systems, the throttle lever’s role is to provide the necessary linkage between the governor’s sensing mechanism and the fuel control apparatus, ensuring that the engine operates within its designed parameters.

Overall, the 3003310 Throttle Lever is a key component in the intricate dance of engine management, working in harmony with various governors and fuel systems to deliver reliable and efficient performance.

Conclusion

The Cummins 3003310 Throttle Lever is a critical component for the efficient and safe operation of commercial trucks. Its robust design, precise calibration, and compatibility with various Cummins engines make it an essential part for maintaining optimal engine performance and fuel efficiency. Proper installation, maintenance, and troubleshooting are key to ensuring the longevity and reliability of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.