This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

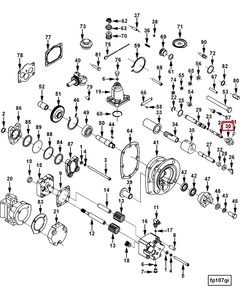

The Throttle Lever Stop, part number 3006342, by Cummins is a component designed to regulate the throttle lever’s movement in commercial trucks. This part ensures that the throttle lever does not exceed its operational limits, thereby maintaining controlled engine speed and performance. Its role is integral to the efficient and safe operation of the vehicle.

Basic Concepts of Throttle Lever Stop

A Throttle Lever Stop is a mechanical device that restricts the movement of the throttle lever. It functions by setting a maximum limit for the throttle’s position, which in turn controls the engine’s speed. This mechanism is vital for preventing over-acceleration and ensuring that the engine operates within safe parameters. The throttle lever stop interacts directly with the throttle linkage and the engine control system to achieve precise speed regulation 1.

Purpose of Throttle Lever Stop 3006342

The Throttle Lever Stop 3006342 is specifically engineered to interact with the throttle linkage and other engine components in commercial trucks. Its primary role is to limit the throttle lever’s travel, ensuring that the engine does not exceed its maximum RPM. This part works in conjunction with the engine’s fuel injection system and other control mechanisms to maintain optimal performance and prevent damage from over-revving 2.

Key Features

The Throttle Lever Stop 3006342 boasts several key features that enhance its functionality. It is constructed from durable materials to withstand the rigors of commercial truck operation. The design includes precise machining to ensure accurate throttle lever positioning. Additionally, it may feature anti-vibration mounts to reduce wear and tear, and a simple yet effective mechanism for easy adjustment and maintenance.

Benefits

The advantages of using the Throttle Lever Stop 3006342 include improved engine performance through consistent speed control, enhanced reliability due to its robust construction, and increased safety by preventing unintended over-acceleration. These benefits contribute to the overall efficiency and longevity of the truck’s engine system 3.

Installation and Integration

Installing the Throttle Lever Stop 3006342 involves several steps to ensure proper integration with the engine system. First, the existing throttle lever stop, if any, should be removed. The new part should then be aligned with the throttle linkage and secured in place using the provided fasteners. It is important to follow the manufacturer’s guidelines to ensure correct installation. Tools such as wrenches and screwdrivers may be required, and it is advisable to consult the vehicle’s service manual for specific procedures.

Troubleshooting Common Issues

Typical problems with the Throttle Lever Stop 3006342 may include improper adjustment, leading to either restricted or excessive throttle movement. Diagnostic steps involve checking the alignment and securement of the part, ensuring it is not damaged, and verifying that it interacts correctly with the throttle linkage. Solutions may range from re-adjusting the stop to replacing damaged components.

Maintenance Tips

Regular maintenance of the Throttle Lever Stop 3006342 is crucial for its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, ensuring that all fasteners are tight, and verifying that the throttle lever moves smoothly within the designated range. Lubricating moving parts can also help reduce friction and wear.

Safety Considerations

When working with the Throttle Lever Stop 3006342, it is important to observe several safety guidelines. Ensure the engine is turned off and the parking brake is engaged before beginning any work. Use appropriate personal protective equipment, such as gloves and safety glasses. Follow all manufacturer recommendations and service manual instructions to prevent accidents and ensure safe operation.

Cummins Overview

Cummins is a well-established company with a rich history in the commercial truck industry. Known for its wide range of high-quality engine and power generation products, Cummins has built a reputation for reliability and performance. The company’s commitment to innovation and customer satisfaction has made it a preferred choice for commercial vehicle operators worldwide.

Throttle Lever Stop for Cummins Engines

The Throttle Lever Stop, part number 3006342, is a critical component in the operation of several Cummins engines. This part is designed to ensure the throttle lever remains within its operational range, preventing over-acceleration and ensuring smooth engine performance. Below is a detailed overview of how this part fits into the listed engines.

K19 and K38 Engines

The K19 and K38 engines are part of Cummins’ line of medium-duty diesel engines. These engines are known for their reliability and efficiency, often used in various commercial applications such as trucks and buses. The Throttle Lever Stop in these engines is essential for maintaining the throttle lever’s position, ensuring that the engine operates within its designed parameters. Proper installation and functionality of this part are crucial for the longevity and performance of the engine.

K50 Engine

The K50 engine is another member of Cummins’ robust engine lineup, designed for heavy-duty applications. This engine is commonly found in large trucks and industrial machinery. The Throttle Lever Stop in the K50 engine serves the same purpose as in the K19 and K38 engines, maintaining the throttle lever’s position and preventing any unintended acceleration. Given the higher power output of the K50 engine, the precision and reliability of the Throttle Lever Stop are even more critical.

NH/NT 855 Engines

The NH/NT 855 engines are part of Cummins’ agricultural engine series, widely used in tractors and other farm equipment. These engines are known for their durability and power, essential for the demanding tasks in agricultural settings. The Throttle Lever Stop in these engines ensures that the throttle lever remains within the operational range, providing consistent and reliable performance. This is particularly important in agricultural applications where the engine is subjected to varying loads and conditions.

Compatibility and Installation

The Throttle Lever Stop, part number 3006342, is designed to fit seamlessly into the listed engines, ensuring compatibility and ease of installation. Cummins engineers have meticulously designed this part to meet the specific requirements of each engine model, ensuring optimal performance and reliability. Proper installation of this part is crucial for maintaining the engine’s performance and preventing potential issues related to throttle control.

Role of Part 3006342 Throttle Lever Stop in Engine Systems

The Throttle Lever Stop, identified by part number 3006342, plays a significant role in ensuring the precise operation of various engine components. Its primary function is to limit the travel of the throttle lever, thereby controlling the amount of fuel delivered to the engine. This is essential for maintaining the desired power output and ensuring efficient engine performance.

In conjunction with the fuel pump and fuel pump housing, the Throttle Lever Stop helps regulate the fuel supply. This is particularly important in systems where the fuel pump is calibrated to specific performance parameters. The stop ensures that the fuel pump does not over-deliver, which could lead to inefficient combustion or even engine damage.

When integrated with the FP & Gov Sump (Fuel Pump & Governor Sump), the Throttle Lever Stop assists in maintaining the correct fuel-air mixture. This is vital for the operation of components like the fuel aftercooler pump and the fuel D B. H. pump, where precise fuel delivery is necessary to achieve optimal cooling and performance.

In systems utilizing the fuel pump AFC-VS (Aftercooler Fuel Control - Variable Speed), the Throttle Lever Stop ensures that the variable speed functionality operates within safe limits. This is important for the fuel pump aftercooler body and the fuel pump housing assembly, where consistent and controlled fuel flow is required to prevent overheating and ensure longevity of the components.

Additionally, the Throttle Lever Stop is instrumental in scenarios where the fuel pump is paired with calibration options such as fuel pump @ cal code or fuel pump and cal. code. These calibrations are designed to fine-tune the engine’s performance under various operating conditions, and the stop ensures that these calibrations are not exceeded.

For engines equipped with the non-AFC VS FP/Gov. Sump, the Throttle Lever Stop provides a mechanical limit that complements the governor’s role in fuel management. This is particularly relevant in maintaining the integrity of the fuel pump body and the fuel pump housing, ensuring they operate within their designed parameters.

In summary, the Throttle Lever Stop (part 3006342) is a key component in the orchestration of fuel delivery and engine performance. It works in tandem with various fuel system components to ensure that the engine operates efficiently and within its specified limits, thereby contributing to the overall reliability and performance of the engine system.

Conclusion

The Throttle Lever Stop, part number 3006342, is a vital component in the operation of Cummins engines, ensuring controlled throttle movement and efficient engine performance. Its robust construction, precise design, and compatibility with various engine models make it an essential part for maintaining the reliability and safety of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.