This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

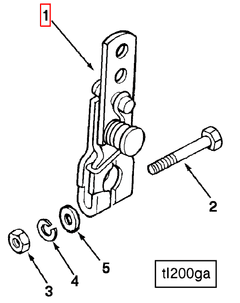

The Cummins 3048295 Throttle Lever is a critical component for commercial trucks, designed to provide precise control over engine speed and power output. Understanding its function and significance can enhance the efficiency and performance of truck operations.

Basic Concepts of Throttle Levers

A throttle lever is a mechanical device used in engine systems to regulate the amount of fuel delivered to the engine. By adjusting the position of the throttle lever, operators can control the engine’s speed and power output, ensuring the engine operates within desired parameters and balancing performance with fuel efficiency 1.

Purpose of the Cummins 3048295 Throttle Lever

The Cummins 3048295 Throttle Lever is engineered to interface with the engine control system of a truck. Its role involves modulating fuel delivery to the engine, which directly affects engine performance. By providing a direct link between the driver and the engine’s fuel system, this throttle lever allows for precise adjustments to engine speed and power, facilitating optimal operation under varying conditions 2.

Key Features

The Cummins 3048295 Throttle Lever is characterized by its robust design and the use of high-quality materials, ensuring durability and reliability in demanding environments. Its design incorporates features that enhance functionality, such as smooth operation and precise control. These characteristics contribute to the lever’s effectiveness in modulating engine performance 3.

Benefits

Utilizing the Cummins 3048295 Throttle Lever offers several advantages. It provides improved engine responsiveness, allowing for quicker adjustments to engine speed and power. This enhances driver control over the vehicle, potentially leading to increases in fuel efficiency and overall performance. The precise modulation of fuel delivery also contributes to more consistent engine operation.

Installation and Integration

Proper installation and integration of the Cummins 3048295 Throttle Lever within a truck’s engine system are essential for optimal performance. This process may involve specific adjustments or calibrations to ensure that the throttle lever operates correctly with the engine control system. Following manufacturer guidelines during installation can help achieve the desired engine performance and responsiveness.

Troubleshooting and Maintenance

Common issues with the Cummins 3048295 Throttle Lever may include difficulties in adjusting engine speed or power output. Troubleshooting these issues often involves checking the mechanical linkage and ensuring that the throttle lever is properly calibrated. Regular maintenance, such as cleaning and inspecting the lever for wear, can help ensure longevity and optimal performance.

Safety Considerations

When handling and working with the Cummins 3048295 Throttle Lever, it is important to observe safety procedures. This includes ensuring that the engine is turned off and the vehicle is securely parked before making any adjustments. Proper handling and the use of appropriate personal protective equipment can prevent accidents or injuries during maintenance or installation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the commercial truck industry, Cummins products are known for their reliability, performance, and innovation. The company’s commitment to quality and customer satisfaction has established it as a trusted name in the field of engine manufacturing.

Throttle Lever Compatibility with Cummins Engines

The Cummins Throttle Lever part number 3048295 is designed to fit a variety of Cummins engines, ensuring smooth and reliable operation across different models. Here is a detailed look at its compatibility:

K-Series Engines

- K19: The throttle lever is engineered to interface seamlessly with the K19 engine, providing precise control over the throttle mechanism.

- K38: Similarly, the K38 engine benefits from the 3048295 throttle lever, which is tailored to match the specific design and operational requirements of this model.

L-Series Engines

- L10 MECHANICAL: The L10 MECHANICAL engine is another model that is compatible with the 3048295 throttle lever. This part ensures that the engine’s throttle response is both accurate and efficient.

M-Series Engines

- M11 CELECT PLUS: The M11 CELECT PLUS engine is designed to work with the 3048295 throttle lever, offering enhanced control and performance features.

- M11 MECHANICAL: The mechanical version of the M11 engine also integrates well with this throttle lever, providing reliable operation and ease of use.

N-Series Engines

- N14 MECHANICAL: The N14 MECHANICAL engine is another model that is compatible with the 3048295 throttle lever, ensuring that the engine’s throttle response is both accurate and efficient.

NH/NT Series Engines

- NH/NT 855: The NH/NT 855 engine is designed to work with the 3048295 throttle lever, ensuring that the engine’s throttle response is both accurate and efficient.

Each of these engines benefits from the precise engineering of the Cummins Throttle Lever part number 3048295, ensuring that the throttle mechanism operates smoothly and reliably.

Role of Part 3048295 Throttle Lever in Engine Systems

The throttle lever, identified by part number 3048295, is a vital component in the orchestration of engine performance. It interfaces directly with the throttle system, allowing for precise control over the engine’s power output.

When the throttle lever is actuated, it adjusts the position of the throttle plate within the carburetor or electronic throttle body. This action regulates the airflow into the engine, which in turn affects the fuel mixture being delivered to the combustion chambers.

In carburetor-equipped engines, the throttle lever’s movement is transmitted to the carburetor’s throttle plate via a series of linkages. This mechanical connection ensures that the airflow is modulated in direct response to the driver’s input, optimizing engine performance across various operating conditions.

For engines with electronic throttle control (ETC) systems, the throttle lever’s movement is detected by a position sensor. This sensor sends signals to the engine control unit (ECU), which then adjusts the throttle plate’s position electronically. This setup allows for more precise control and can incorporate additional inputs from other sensors to enhance performance and efficiency.

The throttle lever also plays a role in the engine’s idle control system. At idle, the lever ensures that the throttle plate is positioned to allow just enough air for the engine to run smoothly without stalling. This is particularly important in maintaining a stable idle speed, especially when the engine is under varying loads, such as when the air conditioning is turned on or off.

In summary, part 3048295 throttle lever is integral to the engine’s ability to respond to driver inputs, maintain stable idle conditions, and optimize performance across a range of operating scenarios. Its interaction with both mechanical and electronic components underscores its importance in the overall engine system.

Conclusion

The Cummins 3048295 Throttle Lever is a crucial component for commercial trucks, offering precise control over engine speed and power output. Its robust design, compatibility with various Cummins engines, and role in enhancing engine performance make it an essential part of the engine system. Proper installation, regular maintenance, and adherence to safety procedures are key to ensuring optimal performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.