This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

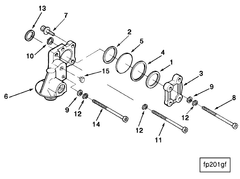

The Throttle Control Bracket (Part #3063503) by Cummins is a component designed to facilitate the operation of commercial trucks. This part plays a role in the truck’s engine system by providing a secure mounting point for the throttle linkage, ensuring precise control over the engine’s throttle. Its significance lies in maintaining the efficiency and reliability of the truck’s engine performance 3.

Purpose and Function

The Throttle Control Bracket serves to connect and support the throttle linkage within the truck’s engine system. By securing the throttle linkage, it allows for the smooth and accurate transmission of driver inputs from the accelerator pedal to the engine’s throttle mechanism. This connection is vital for modulating the engine’s power output in response to driving conditions, thereby contributing to the overall control and performance of the vehicle 4.

Key Features

The Throttle Control Bracket is characterized by its robust design and high-quality materials, which contribute to its durability and precision engineering. Crafted to withstand the rigors of commercial truck operation, it is compatible with Cummins engines, ensuring a precise fit and function. The bracket’s design incorporates features that enhance its stability and reliability, supporting consistent throttle operation 1.

Benefits

Incorporating the Throttle Control Bracket into a truck’s engine system offers several advantages. It contributes to improved throttle response, allowing for more precise control over the engine’s power delivery. This enhancement leads to better overall engine performance and efficiency. Additionally, the bracket’s reliable operation under various driving conditions ensures consistent vehicle performance, supporting the demands of commercial trucking 2.

Installation and Compatibility

Proper installation of the Throttle Control Bracket is crucial for its effective function. The process involves securing the bracket to the engine in accordance with manufacturer guidelines, using the appropriate tools and taking necessary precautions to ensure a secure fit. Compatibility with specific Cummins engine models is ensured through precise engineering, allowing for straightforward integration into the engine system 3.

Maintenance and Troubleshooting

Routine maintenance of the Throttle Control Bracket is recommended to ensure its optimal performance. This includes regular inspections for signs of wear or damage and cleaning as necessary. Common issues may include linkage misalignment or bracket loosening, which can be addressed through readjustment or tightening according to manufacturer recommendations. Proactive maintenance helps prevent potential problems and ensures the bracket continues to function effectively 4.

Safety Considerations

When working with the Throttle Control Bracket, it is important to observe safety guidelines and precautions. This includes proper handling of the component to avoid damage, regular inspection for any signs of wear or malfunction, and adherence to manufacturer recommendations for installation and maintenance. Ensuring the bracket is in good condition and correctly installed contributes to the safe and reliable operation of the vehicle 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. Its product portfolio is designed to meet the diverse needs of customers worldwide, supporting efficient and sustainable transportation solutions 2.

Throttle Control Bracket (Part 3063503) in Cummins Engines

The Throttle Control Bracket, identified by the part number 3063503, is a critical component in the operation of various Cummins engines. This part is designed to secure and position the throttle mechanism, ensuring precise control over the engine’s power output.

In the context of Cummins engines, the Throttle Control Bracket is integral to maintaining the alignment and functionality of the throttle linkage. This bracket is engineered to withstand the rigors of engine operation, providing a stable mounting point for the throttle components.

For the N14 MECHANICAL engine, the Throttle Control Bracket plays a pivotal role in the engine’s throttle system. It ensures that the throttle linkage operates smoothly and efficiently, which is crucial for the engine’s performance and longevity.

The design of the Throttle Control Bracket is such that it can be adapted to fit various configurations of Cummins engines. This adaptability makes it a versatile component, suitable for use in different engine models and applications.

In summary, the Throttle Control Bracket (Part 3063503) is a fundamental part in Cummins engines, ensuring the proper functioning of the throttle system. Its design and placement are critical for maintaining the engine’s performance and reliability 3.

Role of Part 3063503 Throttle Control Bracket in Engine Systems

The Throttle Control Bracket, identified by part number 3063503, is integral to the operation of several key engine components. It serves as a mounting point and support structure for the throttle control mechanism, ensuring precise and reliable modulation of the engine’s air intake.

Integration with Fuel System Components

-

Fuel Filter Head and Damper: The Throttle Control Bracket indirectly influences the performance of the fuel filter head and damper by maintaining consistent engine operation. Stable engine performance ensures that the fuel filter head can effectively remove contaminants from the fuel, while the damper smooths out fuel flow variations, contributing to a steady supply of clean fuel to the engine 4.

-

Fuel Pump: Efficient throttle control, facilitated by the bracket, allows the fuel pump to operate under optimal conditions. Consistent engine RPMs and load conditions mean the fuel pump can deliver fuel at the required pressure and volume, enhancing overall engine efficiency and performance 1.

Coordination with Pace Control and Pump Mechanisms

-

Pace Control: The throttle control system, supported by the bracket, works in tandem with the pace control system to manage the engine’s speed and power output. Accurate throttle positioning ensures that the pace control system can effectively regulate engine RPM, leading to smoother acceleration and deceleration 2.

-

Pump: In systems where additional pumps (such as auxiliary fuel or lubrication pumps) are employed, the stability provided by the Throttle Control Bracket ensures that these pumps operate within their designed parameters. This stability is vital for maintaining the correct pressure and flow rates necessary for the engine’s auxiliary systems 3.

Overall Engine Performance

The Throttle Control Bracket plays a supporting yet significant role in the interplay between these components. By ensuring that the throttle control mechanism is securely mounted and operates smoothly, it contributes to the engine’s overall reliability, efficiency, and performance. This, in turn, allows the fuel system components to function optimally, leading to enhanced engine operation and longevity 4.

Conclusion

The Throttle Control Bracket (Part #3063503) by Cummins is a vital component in the engine systems of commercial trucks, ensuring precise control over the engine’s throttle. Its robust design, compatibility with Cummins engines, and role in maintaining engine performance and reliability make it an essential part for the efficient operation of commercial vehicles. Proper installation, maintenance, and adherence to safety guidelines are crucial for maximizing the benefits of this part.

-

Reif, Konrad. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ ↩ ↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ ↩ ↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ ↩ ↩ ↩ -

Reif, Konrad (Ed.). (2014). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.