This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

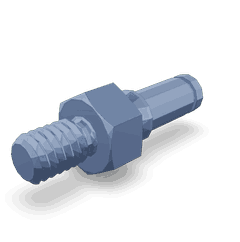

The Throttle Lever Pivot Pin, identified by part number 3284543, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industries. This pin is integral to the operation of heavy-duty trucks, facilitating the precise control of engine speed through the throttle control system.

Basic Concepts

Understanding the Throttle Lever Pivot Pin begins with recognizing its role within the throttle control system. This pin serves as a pivotal point for the throttle lever, allowing it to move smoothly and accurately in response to driver input. It interacts with other components such as the throttle linkage and the accelerator pedal, ensuring that the engine’s speed is adjusted as needed for various driving conditions 1.

Purpose and Function

The Throttle Lever Pivot Pin plays a role in the operation of a truck by enabling the movement of the throttle lever. This movement is important for controlling the amount of air entering the engine, which directly affects engine speed. By providing a stable pivot point, the pin ensures that the throttle lever can be moved with precision, allowing for fine adjustments to engine performance 2.

Key Features

Several key features contribute to the effectiveness of the Throttle Lever Pivot Pin. Its material composition, typically a durable metal alloy, ensures it can withstand the rigors of heavy-duty truck operation. The design of the pin is engineered to offer smooth rotation and minimal friction, which is vital for maintaining precise throttle control. Additionally, any unique attributes, such as corrosion-resistant coatings, enhance its performance and longevity 3.

Benefits

The advantages of using the Throttle Lever Pivot Pin include improved throttle response, which allows for more immediate and accurate adjustments to engine speed. Its enhanced durability ensures reliable performance under various operating conditions, reducing the likelihood of failure or wear. These benefits contribute to the overall efficiency and reliability of the truck’s engine control system.

Installation and Maintenance

Proper installation of the Throttle Lever Pivot Pin is crucial for ensuring optimal performance. It should be securely fitted into its designated position within the throttle control system, following the manufacturer’s guidelines. Regular maintenance, such as checking for signs of wear or corrosion and ensuring that all connections are tight, will help maintain the pin’s functionality and extend its service life.

Troubleshooting

Common issues with the Throttle Lever Pivot Pin may include difficulty in moving the throttle lever, which could indicate wear or corrosion on the pin. Potential causes might be exposure to harsh environmental conditions or lack of maintenance. Troubleshooting steps should involve inspecting the pin for any visible damage, cleaning or lubricating it if necessary, and replacing it if significant wear is detected.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a strong reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. Their product offerings are designed to meet the demanding requirements of various applications, ensuring optimal performance and durability.

Throttle Lever Pivot Pin (Part 3284543) in Cummins Engines

The Throttle Lever Pivot Pin, identified as part number 3284543, is a component in the operation of Cummins engines, including the 6B5.9 series. This part is integral to the throttle mechanism, ensuring smooth and precise control over the engine’s throttle.

In the 6B5.9 engine, the Throttle Lever Pivot Pin connects the throttle lever to the throttle linkage, allowing for the transfer of motion from the operator’s input to the engine’s throttle butterfly valve. This pin must be precisely manufactured to maintain the alignment and functionality of the throttle system, ensuring that the engine responds accurately to the driver’s commands.

The design and placement of the Throttle Lever Pivot Pin in Cummins engines are standardized across various models, including but not limited to the 6B5.9. This standardization facilitates ease of maintenance and repair, as the same part can often be used across different engine models within the Cummins lineup.

For technicians and mechanics, understanding the role of the Throttle Lever Pivot Pin is important for diagnosing and resolving issues related to throttle response and engine performance. Proper installation and maintenance of this part are important for the longevity and efficiency of the engine.

Role of Part 3284543 Throttle Lever Pivot Pin in Engine Systems

The Throttle Lever Pivot Pin is a component that facilitates the smooth operation of the throttle lever within engine systems. This pin acts as a fulcrum, allowing the throttle lever to pivot and control the flow of fuel or air into the engine.

When the throttle lever is manipulated, either manually by the operator or automatically by the engine control system, the pivot pin ensures that the movement is precise and consistent. This precision is vital for maintaining the desired engine performance and ensuring that the engine responds accurately to the throttle inputs.

The pivot pin interfaces directly with the throttle lever and is typically secured in place by other components such as brackets or housings. Its role is to provide a stable yet flexible connection point that can withstand the mechanical stresses induced during engine operation.

Conclusion

In summary, the Throttle Lever Pivot Pin (part number 3284543) is integral to the functionality of the throttle system, enabling efficient and reliable control over the engine’s power output. Its design, material composition, and precise manufacturing ensure that it can withstand the rigors of heavy-duty truck operation, providing smooth and accurate throttle control. Proper installation, maintenance, and understanding of this part are crucial for ensuring the optimal performance and longevity of Cummins engines.

-

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.