This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

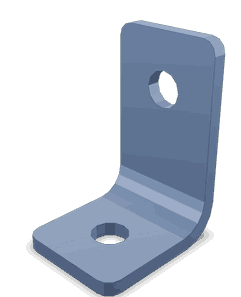

The Throttle Control Bracket Assembly, part number 3395964, by Cummins is a component designed to facilitate the operation of the throttle control system in heavy-duty trucks. This assembly is integral to the precise management of engine speed and power output, contributing to the efficient and reliable performance of the vehicle.

Function and Operation

The Throttle Control Bracket Assembly operates by securely mounting the throttle control mechanism to the engine. It ensures that the throttle linkage remains in proper alignment and allows for smooth and accurate throttle response. The assembly interacts with various engine components, including the throttle actuator and the accelerator pedal, to translate driver inputs into engine speed adjustments. This interaction is crucial for maintaining the desired engine performance under varying load conditions 1.

Key Features

This Cummins part is constructed from durable materials, ensuring longevity and resistance to the harsh conditions encountered in heavy-duty truck operations. Its design incorporates precise engineering to provide a stable and secure mounting point for the throttle control components. Unique characteristics of this assembly include its robust build and the integration of corrosion-resistant coatings, which enhance its durability in demanding environments 2.

Role in Truck Operation

In the operation of a truck, the Throttle Control Bracket Assembly plays a significant role by ensuring that the throttle system functions correctly. It contributes to the overall engine performance by maintaining the integrity of the throttle linkage and facilitating accurate engine speed control. This, in turn, affects the truck’s efficiency, as proper throttle management is key to optimizing fuel consumption and power delivery 3.

Benefits

The advantages of the Throttle Control Bracket Assembly include improved engine control, which leads to better drivability and responsiveness. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. Additionally, the assembly’s design contributes to the overall robustness of the throttle system, enhancing the truck’s performance and longevity 4.

Installation and Compatibility

Proper installation of the Throttle Control Bracket Assembly is vital for its function and the truck’s performance. It is designed to be compatible with specific Cummins engine models, ensuring a precise fit and optimal operation. Installation procedures should follow manufacturer guidelines to maintain the integrity of the throttle system and ensure safe and effective operation.

Maintenance and Troubleshooting

Regular maintenance of the Throttle Control Bracket Assembly involves inspecting for signs of wear or damage and ensuring that all connections are secure. Troubleshooting common issues may include checking for proper alignment of the throttle linkage and verifying that the assembly is free from obstructions. Adhering to a maintenance schedule can prevent potential problems and ensure the continued reliable operation of the throttle system.

Safety Considerations

When working with the Throttle Control Bracket Assembly, it is important to observe safety guidelines to protect mechanics and operators. This includes ensuring that the engine is off and cooled down before beginning any work, using appropriate personal protective equipment, and following all manufacturer-recommended procedures to avoid injury or damage to the component.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company’s product range includes a variety of engines and components designed for heavy-duty applications, reflecting its commitment to performance and reliability.

Throttle Control Bracket Assembly for Cummins Engines

The Throttle Control Bracket Assembly, part number 3395964, is a critical component in the operation of certain Cummins engines. This part is designed to securely mount and position the throttle control mechanism, ensuring precise and reliable engine operation.

Compatibility with Cummins Engines

G5.9 and G8.3 Engines

The Throttle Control Bracket Assembly is specifically engineered to fit the G5.9 and G8.3 Cummins engines. These engines are known for their robust performance and reliability, often used in various industrial and commercial applications. The bracket assembly ensures that the throttle linkage is properly aligned and tensioned, which is essential for maintaining optimal engine performance and efficiency.

Grouping of Engines

The G5.9 and G8.3 engines share several common features, making them suitable for the same throttle control bracket assembly. Both engines are part of the Cummins range that emphasizes durability and power, making them ideal for heavy-duty applications. The bracket assembly’s design accommodates the specific mounting points and configurations of these engines, ensuring a seamless fit and function.

Installation and Functionality

When installed, the Throttle Control Bracket Assembly provides a stable platform for the throttle linkage. This stability is crucial for the smooth operation of the engine’s throttle system. The bracket assembly is typically mounted to the engine block or intake manifold, depending on the specific engine model. Its role is to maintain the correct position of the throttle linkage, which directly affects the engine’s responsiveness and overall performance.

Importance of Proper Installation

Proper installation of the Throttle Control Bracket Assembly is vital for the engine’s performance. Any misalignment or improper tensioning can lead to issues such as throttle lag, inconsistent engine response, and potential mechanical failures. Technicians should follow the manufacturer’s guidelines for installation to ensure that the bracket assembly is correctly positioned and secured.

Maintenance Considerations

Regular maintenance of the Throttle Control Bracket Assembly is essential to ensure its longevity and proper function. Periodic inspections should be conducted to check for any signs of wear, corrosion, or damage. Any issues should be addressed promptly to prevent potential engine performance problems. Lubrication of moving parts, if applicable, can also help maintain the assembly’s smooth operation.

Role of Part 3395964 Throttle Control Bracket Assembly in Engine Systems

The Throttle Control Bracket Assembly, identified as part 3395964, is an integral component in the orchestration of various engine systems. It serves as a pivotal mounting point and support structure for the throttle lever, which is directly manipulated by the operator to control engine speed and power output.

Integration with the Throttle and Governor Systems

In conjunction with the throttle, the bracket assembly allows for precise modulation of air intake, which in turn affects fuel delivery and combustion efficiency. The governor, a device that maintains consistent engine speed under varying loads, interacts with the throttle control bracket assembly to ensure stable operation. The assembly provides a stable base for the governor’s mechanical components, enabling it to adjust the throttle lever position as needed to maintain the desired engine speed.

Interaction with the Fuel Shutoff Valve

The throttle control bracket assembly also plays a role in the operation of the fuel shutoff valve. This valve is essential for stopping fuel flow to the engine, effectively shutting it down. The bracket assembly ensures that the mechanical linkage between the throttle lever and the fuel shutoff valve is secure and operates smoothly. This linkage is vital for the immediate and reliable cessation of engine operation when required.

Mechanical Lever System

The assembly is designed to accommodate the mechanical lever system, which translates the operator’s input into actionable movements within the engine. This system is responsible for the direct control of the throttle valve, which regulates the amount of air entering the engine. The throttle control bracket assembly ensures that this lever system is correctly aligned and tensioned, allowing for responsive and accurate throttle control.

Conclusion

In summary, the Throttle Control Bracket Assembly, part number 3395964, is a foundational component that ensures the proper function and interaction of the throttle, governor, fuel shutoff valve, and mechanical lever system within the engine. Its role in maintaining the structural integrity and operational precision of these systems is essential for the overall performance and reliability of the engine.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Goodnight, Nicholas, and Kirk Van Gelder. Automotive Braking Systems. Jones & Bartlett Learning, 2018.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.