This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

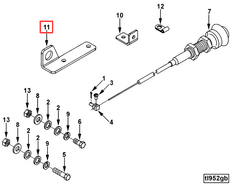

The Throttle Control Bracket 3396169, manufactured by Cummins, is a component designed to facilitate the operation of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems that contribute to the efficiency and reliability of truck engines. This Cummins part is integral to the engine’s operation, ensuring that the throttle system functions correctly and efficiently.

Basic Concepts of Throttle Control Brackets

A Throttle Control Bracket is a mechanical component that plays a role in the engine system by securing and guiding the throttle linkage. This bracket ensures that the throttle valve opens and closes in response to driver input, thereby regulating the amount of air entering the engine. By controlling air intake, the bracket helps manage engine speed and power output. It interacts with other components such as the accelerator pedal, throttle position sensor, and the engine control unit to maintain optimal performance 1.

Purpose and Role in Truck Operation

The 3396169 Throttle Control Bracket is specifically designed to enhance the operation of trucks by providing a stable mount for the throttle linkage. This bracket contributes to engine management by ensuring precise control over the throttle valve. Accurate throttle control is vital for maintaining consistent engine performance, fuel efficiency, and overall drivability. The bracket’s role in securing the throttle linkage helps prevent issues such as throttle sticking or inconsistent engine response 2.

Key Features

The 3396169 Throttle Control Bracket boasts several key features that enhance its functionality. Constructed from durable materials, it is designed to withstand the rigors of commercial truck operation. The bracket features a robust design that ensures a secure fit for the throttle linkage. Additionally, it includes precise mounting points that align with the truck’s throttle system, facilitating easy installation and reliable operation. The design also incorporates features that reduce vibration and wear, contributing to the bracket’s longevity.

Benefits

The 3396169 Throttle Control Bracket offers several benefits to truck operators. By providing a stable and secure mount for the throttle linkage, it contributes to improved engine efficiency and reliability. The precise control over the throttle valve ensures consistent engine performance, which can lead to better fuel economy. Additionally, the durable construction of the bracket enhances its resistance to wear and tear, reducing the need for frequent replacements and maintenance.

Installation Process

Installing the 3396169 Throttle Control Bracket requires careful attention to detail to ensure a secure fit. Begin by disconnecting the throttle linkage from the existing bracket. Position the new bracket in place, ensuring it aligns with the mounting points on the truck’s throttle system. Use the appropriate tools to secure the bracket with the provided fasteners. Double-check the alignment and tightness of the fasteners to ensure the bracket is firmly in place. Reconnect the throttle linkage to the new bracket, making sure all connections are secure. Test the throttle operation to confirm proper installation.

Troubleshooting Common Issues

Common issues with Throttle Control Brackets may include misalignment or wear. If the throttle does not respond correctly, check the alignment of the bracket and ensure it is securely mounted. Worn brackets may need replacement to restore proper function. Regular inspection and maintenance can help identify and address these issues before they lead to significant problems.

Maintenance Tips

To prolong the lifespan of the 3396169 Throttle Control Bracket, routine maintenance is recommended. Inspect the bracket regularly for signs of wear or damage. Clean the bracket and its mounting points to remove any dirt or debris that could affect performance. Ensure all fasteners are tight and the throttle linkage is properly connected. If significant wear is detected, consider replacing the bracket to maintain optimal engine performance.

About Cummins

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. With a history of innovation and reliability, Cummins offers a wide range of products designed to enhance the performance and efficiency of commercial vehicles. The company’s reputation for quality is built on a commitment to engineering excellence and customer satisfaction, making Cummins parts, including the 3396169 Throttle Control Bracket, a trusted choice for truck operators.

Throttle Control Bracket (Part 3396169) Compatibility with Cummins Engines

The Throttle Control Bracket, identified by part number 3396169 and manufactured by Cummins, is a critical component in the engine’s throttle system. This part is designed to ensure the proper alignment and operation of the throttle linkage, which is essential for maintaining engine performance and efficiency.

G8.3 Engine Series

The Throttle Control Bracket (3396169) is specifically engineered to fit within the G8.3 engine series. This series includes various engine models that share common design principles and components, making the bracket a versatile fit across multiple variants. The G8.3 engines are known for their robust construction and reliability, often used in heavy-duty applications where consistent performance is crucial.

The bracket’s design ensures it can withstand the operational stresses and environmental conditions typical of these engines. Its precise fitment is crucial for the smooth operation of the throttle mechanism, which directly impacts the engine’s responsiveness and overall performance.

Installation and Functionality

When installed, the Throttle Control Bracket secures the throttle linkage to the engine, ensuring that the throttle plate opens and closes in response to the driver’s input. This precise control is vital for maintaining the engine’s speed and power output, especially in demanding applications.

Importance of Proper Fitment

The compatibility of the Throttle Control Bracket with the G8.3 engine series underscores the importance of using genuine parts for maintenance and repairs. Proper fitment and installation are essential to avoid issues such as throttle lag, inconsistent power delivery, and potential mechanical failures. Cummins’ design ensures that the bracket integrates seamlessly with the engine’s architecture, providing a reliable and efficient solution for maintaining the throttle system’s integrity.

Role of Part 3396169 Throttle Control Bracket in Engine Systems

The 3396169 throttle control bracket is integral to the efficient operation of engine systems, particularly in the coordination between the throttle lever and the throttle mechanism. This component serves as a pivotal mounting point, ensuring that the throttle lever is securely attached and can transmit motion effectively to the throttle mechanism.

When the operator manipulates the throttle lever, the motion is transferred through the 3396169 throttle control bracket to the throttle mechanism. This transfer is essential for adjusting the engine’s power output, as it controls the amount of air entering the engine, which in turn affects fuel delivery and combustion.

The bracket’s design allows for precise alignment and smooth operation, minimizing any potential for misalignment that could lead to inefficient engine performance or increased wear on connected components. Its robust construction ensures durability under the varying loads and stresses encountered during engine operation.

Conclusion

In summary, the 3396169 throttle control bracket plays a significant role in maintaining the integrity and performance of the throttle system, ensuring that the engine responds accurately and reliably to operator inputs. Its compatibility with Cummins engines, particularly the G8.3 series, highlights the importance of using genuine parts for optimal engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.