This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

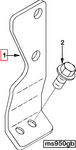

The Throttle Control Bracket 3866360, manufactured by Cummins, is a critical component for the operation of commercial trucks. Cummins, a prominent name in engine manufacturing, produces this bracket to ensure precise throttle control, which is essential for the efficient and responsive performance of truck engines.

Function and Operation

This Cummins part operates within the truck’s engine system by facilitating the connection between the throttle linkage and the accelerator pedal. It allows for the smooth and accurate transmission of driver inputs from the pedal to the throttle, which in turn regulates the amount of air entering the engine. This interaction is vital for maintaining the desired engine speed and power output 1.

Purpose of the Throttle Control Bracket

The primary role of the Throttle Control Bracket is to manage the throttle position, ensuring that the engine responds accurately to driver commands. By maintaining a consistent and smooth operation of the throttle, this bracket contributes to the overall efficiency and responsiveness of the truck’s engine. It helps in achieving a balanced engine performance, which is important for both the truck’s operation and driver satisfaction 2.

Key Features

The Throttle Control Bracket 3866360 is designed with specific features that enhance its performance and durability. It is constructed from high-quality materials to withstand the rigors of commercial truck use. The bracket includes precise mounting points that ensure a secure fit within the engine compartment. Additionally, its design incorporates features that reduce the likelihood of wear and tear, contributing to its longevity 3.

Benefits

The advantages provided by the Throttle Control Bracket include improved throttle response and enhanced engine control. These benefits lead to a more responsive driving experience and can potentially result in fuel efficiency gains. The bracket’s role in maintaining smooth engine operation contributes to the overall performance of the truck and enhances driver satisfaction 4.

Installation and Compatibility

Proper installation of the Throttle Control Bracket is important for its function and the truck’s performance. It requires specific tools and procedures to ensure it is correctly mounted and aligned within the engine system. Compatibility with Cummins engine models and other truck makes is a consideration for ensuring optimal performance and integration within the engine system.

Maintenance and Troubleshooting

Routine maintenance of the Throttle Control Bracket is recommended to ensure its longevity and optimal performance. This includes regular inspections for signs of wear or damage. Troubleshooting common issues such as throttle sticking or uneven acceleration may involve cleaning or adjusting the bracket. Addressing these issues promptly can prevent more significant problems and maintain the efficiency of the truck’s engine.

Cummins Overview

Cummins Inc. is a leader in the engine manufacturing industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance engine components, Cummins has established a strong reputation in the commercial truck sector. The company’s dedication to excellence is reflected in its product offerings, which are designed to meet the demanding requirements of commercial vehicle operations.

Compatibility of 3866360

The Throttle Control Bracket, identified by part number 3866360, is a critical component in the engine’s throttle system. This bracket is designed to securely mount the throttle control mechanism, ensuring precise and reliable operation of the engine’s throttle.

Engine Compatibility

This part is specifically engineered to fit the following Cummins engine models:

- 6B5.9

The Throttle Control Bracket 3866360 is integral to the engine’s throttle linkage, providing a stable mounting point that allows for smooth and controlled throttle operation. The bracket’s design ensures that the throttle mechanism can respond accurately to the operator’s inputs, which is essential for maintaining engine performance and efficiency.

Grouping of Compatible Engines

While the Throttle Control Bracket 3866360 is primarily associated with the 6B5.9 engine, it is also compatible with other Cummins engines within the same family or series that share similar design specifications. This compatibility ensures that the bracket can be used across multiple engine models, providing a versatile solution for engine maintenance and repair.

Installation Considerations

When installing the Throttle Control Bracket 3866360, it is important to follow the manufacturer’s guidelines to ensure proper fitment and function. This includes verifying that the bracket is correctly aligned with the throttle linkage and that all mounting points are secure and properly tightened. Proper installation is crucial for maintaining the integrity of the engine’s throttle system and ensuring optimal performance.

Role of 3866360 in Engine Systems

The Throttle Control Bracket, identified by part number 3866360, is an essential component in the orchestration of engine performance. It serves as a pivotal mounting point for the throttle control system, ensuring precise and reliable operation of the engine’s throttle mechanism.

Integration with the Control System

In the context of engine control systems, the Throttle Control Bracket securely attaches the throttle body to the engine, allowing for smooth and accurate modulation of air intake. This bracket facilitates the connection between the electronic control unit (ECU) and the throttle body, enabling the ECU to adjust the throttle opening based on driving conditions and engine load. The bracket’s sturdy construction ensures that the throttle body remains in the correct position, which is vital for maintaining engine efficiency and responsiveness.

Interaction with the Manual Throttle Lever

When considering manual throttle systems, the Throttle Control Bracket plays a significant role in the mechanical linkage between the driver’s input via the accelerator pedal and the throttle body. The bracket provides a stable base for the manual throttle lever to pivot, translating the driver’s foot movement into precise throttle adjustments. This direct mechanical connection ensures that the throttle responds immediately to the driver’s commands, which is particularly important in applications where fine-tuned control is necessary, such as in racing or high-performance vehicles.

Ensuring System Harmony

The Throttle Control Bracket is designed to work in concert with other engine components, such as the intake manifold and the fuel injection system. By providing a solid mounting point, it helps maintain the alignment and integrity of the throttle system, which is essential for consistent engine performance. The bracket’s role in the system is to offer a reliable interface that allows for the seamless integration of various throttle control mechanisms, whether they are electronic, manual, or a combination of both.

Conclusion

In summary, the Throttle Control Bracket (part 3866360) is a fundamental component that ensures the throttle system operates within the designed parameters, contributing to the overall performance and reliability of the engine.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Asef, P., Padmanaban, S., & Lapthorn, A. (2022). Modern Automotive Electrical Systems. Wiley.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.