This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

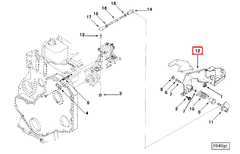

The Throttle Control Bracket 3919921, designed by Cummins, is a component integral to the operation of heavy-duty trucks. This part provides a secure mounting point for the throttle linkage, ensuring the proper transmission of driver inputs from the accelerator pedal to the engine’s throttle mechanism. Its role is significant in maintaining the integrity and efficiency of the throttle system, which is essential for the overall performance and drivability of the vehicle 3.

Function and Operation

The Throttle Control Bracket 3919921 operates as a critical connection point within the truck’s engine system. It interfaces with the throttle linkage and accelerator pedal, translating the driver’s pedal movements into precise adjustments of the engine’s throttle valve. This interaction modulates air intake into the engine, thereby controlling engine speed and power output. The bracket’s design ensures that these adjustments are made smoothly and accurately, contributing to the engine’s responsiveness and efficiency 1.

Key Features

Characterized by its robust design and high-quality materials, the Throttle Control Bracket 3919921 is engineered to withstand the demanding conditions of heavy-duty truck operation. It features a durable construction that enhances its performance and longevity. The bracket’s design includes precise mounting points and alignment features, ensuring a secure and stable connection to the engine and throttle linkage. These attributes contribute to the bracket’s reliability and effectiveness in managing the throttle system 2.

Role in Truck Operation

In the operation of a heavy-duty truck, the Throttle Control Bracket 3919921 plays a role in managing the throttle system by providing a stable and secure mounting solution for the throttle linkage. This ensures that the driver’s inputs via the accelerator pedal are accurately translated into engine throttle adjustments. The bracket’s role is essential in maintaining precise control over engine speed and power delivery, which are vital for the truck’s performance, fuel efficiency, and drivability 3.

Benefits

The Throttle Control Bracket 3919921 offers several advantages, including improved throttle response, which allows for more immediate and precise adjustments to engine speed and power. Its durable construction contributes to enhanced longevity and reliability, reducing the need for frequent replacements or repairs. Additionally, by ensuring accurate throttle control, the bracket plays a role in optimizing engine efficiency, which can lead to better fuel economy and overall performance 1.

Troubleshooting and Maintenance

Common issues with the Throttle Control Bracket 3919921 may include wear and tear, misalignment, or damage due to exposure to harsh operating conditions. Regular inspection and maintenance are recommended to ensure optimal performance and longevity. This includes checking for signs of wear, ensuring proper alignment, and securing all fasteners. Addressing these issues promptly can help prevent more significant problems and ensure the efficient operation of the throttle system 2.

Installation Considerations

When installing the Throttle Control Bracket 3919921, it is important to consider factors such as proper alignment with the engine and throttle linkage, secure fastening to prevent movement or vibration, and compatibility with other engine components. Careful attention to these details during installation can help ensure the bracket functions effectively and contributes to the overall performance and reliability of the truck’s engine system 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry, particularly in the realm of heavy-duty truck components. The company’s commitment to excellence and customer satisfaction is reflected in its extensive product range and the performance of its components, such as the Throttle Control Bracket 3919921 2.

Compatibility with Cummins Engines

The Throttle Control Bracket 3919921 is engineered to be compatible with a range of Cummins engines, including but not limited to the 6B5.9 series. This compatibility ensures that the bracket can be used across multiple engine models, simplifying maintenance and repair processes 2.

Importance in Engine Operation

The proper functioning of the Throttle Control Bracket 3919921 is essential for the overall operation of the engine. It helps in maintaining the correct air-fuel mixture, which is vital for efficient combustion and power output. Additionally, a well-functioning throttle control bracket contributes to the longevity of the engine by preventing undue stress on the throttle linkage and related components 1.

Maintenance Considerations

Regular inspection of the Throttle Control Bracket 3919921 is recommended to ensure it remains in good condition. Over time, wear and tear can occur, which may affect the bracket’s ability to hold the throttle linkage securely. Any signs of damage or excessive wear should be addressed promptly to avoid potential engine performance issues 2.

Role of Throttle Control Bracket in Engine Systems

The throttle control bracket, specifically part 3919921, is integral to the efficient operation of engine systems. It serves as a pivotal mounting point for the throttle linkage, which connects the throttle body to the accelerator pedal. This bracket ensures precise and consistent control over the airflow into the engine, directly influencing the engine’s performance and responsiveness 3.

Conclusion

The Throttle Control Bracket 3919921 by Cummins is a critical component in the engine assembly, ensuring proper positioning and functionality of the throttle mechanism. Its robust design, compatibility with various Cummins engines, and essential role in engine operation make it a vital part of heavy-duty truck systems. Regular maintenance and proper installation are key to ensuring the longevity and efficiency of this Cummins part.

-

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩ ↩ ↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4310840, 2023.

↩ ↩ ↩ ↩ ↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.