This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

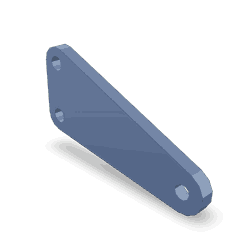

The Throttle Control Bracket 3934196, manufactured by Cummins, is a critical component in the commercial trucking industry. This bracket is essential for the precise control of engine speed and power delivery through its role in the throttle system.

Function and Operation

The Throttle Control Bracket 3934196 connects the throttle linkage to the accelerator pedal within the truck’s engine system. When the driver presses the accelerator pedal, the bracket translates this action into movement of the throttle linkage, which adjusts the throttle valve. This process regulates the amount of air entering the engine, thereby controlling engine speed and power output 1.

Purpose of the Throttle Control Bracket

The primary function of the Throttle Control Bracket is to manage the throttle system, ensuring that the driver has precise control over engine speed and power delivery. By providing a stable and secure connection between the accelerator pedal and the throttle linkage, the bracket contributes to the smooth and responsive operation of the engine 2.

Key Features

The Throttle Control Bracket 3934196 is designed with durability and precision engineering in mind. Crafted from high-quality materials, it is built to withstand the rigors of commercial truck operation. Its design ensures compatibility with Cummins engines, offering a reliable and efficient solution for throttle control 3.

Benefits

The advantages of the Throttle Control Bracket include improved throttle response, which allows for more precise driver control over engine performance. This can lead to an enhanced driving experience and potentially contribute to fuel efficiency and overall engine performance. The bracket’s robust construction and precise engineering also ensure long-term reliability and durability 4.

Installation and Compatibility

Proper installation of the Throttle Control Bracket is crucial for its effective operation. It requires the use of specific tools and adherence to manufacturer guidelines to ensure a secure fit. Compatibility with specific Cummins engine models should be verified to ensure optimal performance and integration within the engine system.

Maintenance and Troubleshooting

Routine maintenance of the Throttle Control Bracket involves regular inspection for signs of wear or damage, ensuring all connections are secure, and cleaning any debris that may affect its operation. Troubleshooting common issues such as throttle sticking or uneven acceleration may involve checking the bracket’s alignment and condition, as well as ensuring the throttle linkage moves freely.

Safety Considerations

When working with the Throttle Control Bracket, it is important to observe safety protocols. This includes ensuring the engine is off and the vehicle is securely parked before beginning any work. Proper handling and secure installation of the bracket are vital to prevent accidents and ensure the component functions correctly.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the commercial trucking industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction.

Compatibility with Cummins Engines

-

4B3.9 Engine Series: The 3934196 throttle control bracket is specifically engineered to fit the 4B3.9 engine series. This engine is known for its robust performance and is commonly used in various industrial and commercial applications. The bracket ensures that the throttle linkage is properly aligned and secured, contributing to smooth engine operation and longevity.

-

6B5.9 Engine Series: Similarly, the 3934196 throttle control bracket is also compatible with the 6B5.9 engine series. This engine is part of Cummins’ lineup of high-performance diesel engines, often utilized in heavy-duty applications. The bracket’s precise fit and robust construction help maintain the integrity of the throttle system, ensuring consistent engine performance and efficiency.

Importance of the Throttle Control Bracket

The throttle control bracket plays a pivotal role in the engine’s throttle system. It ensures that the throttle linkage is correctly positioned, which is vital for the engine’s responsiveness and overall performance. By maintaining the proper alignment of the throttle components, this bracket helps prevent wear and tear, ultimately extending the engine’s lifespan.

Installation and Maintenance

When installing the 3934196 throttle control bracket, it is essential to follow the manufacturer’s guidelines to ensure a proper fit and function. Regular maintenance checks should be conducted to verify that the bracket remains securely fastened and free from any signs of wear or damage. Proper maintenance of this component can prevent potential issues with the engine’s throttle system, ensuring smooth and reliable operation.

Role of the Throttle Control Bracket in Engine Systems

The 3934196 Throttle Control Bracket is an integral component in the orchestration of engine performance, specifically in the management of the throttle system. This bracket serves as the pivotal mounting point for the throttle lever, ensuring its secure and precise attachment to the engine assembly.

When the throttle lever is actuated, either manually by the operator or automatically by the vehicle’s control system, the 3934196 bracket transmits this motion to the throttle plate within the carburetor or the throttle body in fuel-injected systems. This transmission is achieved through a series of linkages and, in some designs, cables that connect the lever to the throttle mechanism.

The stability provided by the 3934196 bracket is essential for maintaining the integrity of the throttle’s operation. It allows for smooth and consistent modulation of the airflow into the engine, which directly influences the engine’s RPM and, consequently, its power output. The bracket’s design must account for the dynamic forces exerted during operation, ensuring that the throttle lever’s movement is translated accurately without undue stress on the connecting components.

In addition to its functional role, the 3934196 bracket also contributes to the overall reliability of the throttle system. By providing a solid foundation for the throttle lever, it helps to prevent wear and tear on the throttle linkage, which can lead to imprecise throttle response or even failure in extreme cases.

The integration of the 3934196 bracket within the engine system is a testament to the meticulous engineering that goes into ensuring every component works in harmony to deliver optimal engine performance. Its role may be understated, but its contribution to the throttle system’s efficiency and durability is undeniable.

Conclusion

The Throttle Control Bracket 3934196 by Cummins is a vital component in the operation of commercial trucks, ensuring precise control over engine speed and power delivery. Its robust design, compatibility with Cummins engines, and role in maintaining the integrity of the throttle system make it an essential part of the engine’s performance and reliability.

-

Maclaurin, Bruce. High Speed Off-Road Vehicles. Wiley, 2018.

↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.