This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

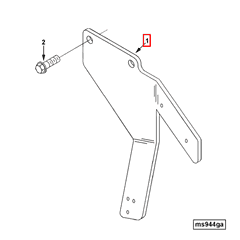

Introduction to Throttle Control Brackets

Throttle control brackets are essential components in the engine systems of commercial trucks, ensuring the smooth and efficient operation of the throttle mechanism. These brackets secure the throttle linkage, maintaining the alignment and functionality necessary for optimal engine performance.

The Role of a Throttle Control Bracket in Truck Engines

A throttle control bracket, such as the Cummins part #4003606, serves several critical functions within the engine:

- Secures Throttle Linkage: It holds the throttle linkage in place, preventing misalignment and ensuring consistent throttle response.

- Maintains Engine Performance: By keeping the throttle components aligned, it helps maintain the engine’s performance and efficiency.

- Reduces Wear and Tear: Proper alignment and secure mounting of the throttle linkage reduce unnecessary wear on the components, extending their lifespan 1.

How a Throttle Control Bracket Works

The throttle control bracket works in conjunction with the throttle pedal and the throttle body. When the driver presses the throttle pedal, the bracket ensures that the throttle linkage moves smoothly and precisely, opening the throttle body to allow more air into the engine. This increased airflow enhances engine power and responsiveness 2.

Importance of the Cummins Throttle Control Bracket

Cummins, a renowned manufacturer of heavy-duty truck engines, designs the throttle control bracket to meet the rigorous demands of commercial truck operations. The Cummins part #4003606 is engineered for durability and reliability, ensuring that it can withstand the harsh conditions and heavy loads typical in commercial trucking 3.

Troubleshooting and Maintenance Tips

Regular maintenance and timely troubleshooting are essential for the longevity and performance of the throttle control bracket:

- Inspection: Regularly inspect the bracket for signs of wear, corrosion, or damage. Check that all bolts and fasteners are tight and secure.

- Cleaning: Keep the bracket clean and free from dirt and debris, which can cause corrosion and affect performance.

- Alignment Check: Ensure that the throttle linkage is properly aligned. Misalignment can lead to poor throttle response and engine performance issues.

- Replacement: If the bracket shows signs of significant wear or damage, replace it promptly to avoid potential engine problems.

Cummins: A Leader in Engine Manufacturing

Cummins is a global power leader and a Fortune 500 company, known for its high-quality, reliable, and efficient engines. Cummins engines are widely used in commercial trucks, construction equipment, and agricultural machinery. Their commitment to innovation and quality ensures that their parts, including the throttle control bracket, meet the highest standards of performance and durability.

Compatibility with Cummins Engines

The Throttle Control Bracket 4003606 is compatible with a range of Cummins engines, including but not limited to:

- 6C8.3: This engine model benefits from the precise fit and robust construction of the 4003606 bracket, ensuring smooth and reliable throttle operation.

The bracket’s design is tailored to fit seamlessly with the engine’s architecture, providing a secure mounting point for the throttle linkage. This compatibility is crucial for maintaining the engine’s operational integrity and preventing any potential issues related to throttle control.

Importance in Engine Performance

The proper installation of the Throttle Control Bracket 4003606 is vital for the overall performance of the engine. It ensures that the throttle linkage operates smoothly, which is essential for maintaining consistent engine speed and power output. This component also helps in reducing wear and tear on other parts of the throttle system, thereby extending the engine’s lifespan.

Installation and Maintenance

When installing the Throttle Control Bracket 4003606, it is important to follow the manufacturer’s guidelines to ensure a secure fit. Regular maintenance checks should be performed to verify that the bracket remains in good condition and is not showing signs of wear or damage. Any issues with the bracket should be addressed promptly to prevent potential engine performance problems.

Role of Part 4003606 Throttle Control Bracket in Engine Systems

The 4003606 Throttle Control Bracket is an integral component in the orchestration of engine performance, specifically within the throttle control system. Its primary function is to provide a stable mounting point for the manual throttle lever, ensuring precise and reliable throttle operation.

When the manual throttle lever is actuated by the operator, the 4003606 Throttle Control Bracket transmits this motion to the throttle linkage or cable. This transmission is vital for modulating the engine’s power output in response to the operator’s commands. The bracket’s design allows for smooth and consistent movement, minimizing any potential play or misalignment that could otherwise lead to inconsistent throttle response.

In addition to its role in the mechanical linkage, the 4003606 Throttle Control Bracket often interfaces with other components such as the throttle position sensor (TPS). The TPS monitors the position of the throttle lever and sends this data to the engine control unit (ECU), allowing for fine-tuned adjustments to fuel delivery and ignition timing. The bracket ensures that the TPS remains in the correct position relative to the throttle lever, enhancing the accuracy of the sensor’s readings.

Furthermore, the 4003606 Throttle Control Bracket contributes to the overall durability and longevity of the throttle system. By providing a robust mounting solution, it helps to mitigate the effects of vibration and stress that are inherent in engine operation. This reliability is essential for maintaining consistent engine performance over time.

Conclusion

Understanding the role and importance of the Cummins throttle control bracket, part #4003606, is crucial for engineers, mechanics, truck drivers, and fleet operators. Proper maintenance and troubleshooting of this component can significantly impact the performance and longevity of the truck’s engine, ensuring smooth and efficient operation on the road.

-

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.