This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

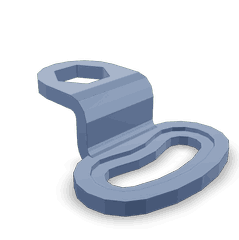

The Throttle Control Bracket, part number 4009917, manufactured by Cummins, is a critical component for commercial trucks. Cummins is renowned for producing reliable and high-performance parts, and this throttle control bracket is no exception. It is integral to the efficient management of engine throttle and overall vehicle performance.

Basic Concepts of Throttle Control Brackets

A Throttle Control Bracket is a mechanical component that secures the throttle linkage, ensuring the throttle valve opens and closes in response to driver input. This regulates the amount of air entering the engine, thereby controlling the engine’s power output. The bracket interacts with the throttle pedal, linkage, and throttle body to ensure precise and consistent throttle response 1.

Purpose of the Throttle Control Bracket

The Throttle Control Bracket, part 4009917, is designed to manage the engine throttle in trucks. It provides a stable mounting point for the throttle linkage, ensuring smooth and accurate operation of the throttle valve. This allows for precise control over engine speed and power, which is essential for efficiency and drivability 2.

Key Features

The Throttle Control Bracket 4009917 is characterized by several key features that enhance its performance and durability. It is engineered to withstand the rigors of commercial truck operation and is constructed from high-quality materials that resist wear and corrosion. The bracket may also feature precise machining for accurate fitment and robust construction to handle high stress loads 3.

Benefits

The advantages of the Throttle Control Bracket 4009917 include improved engine efficiency, enhanced reliability, and ease of maintenance. By ensuring a stable and accurate throttle linkage, the bracket contributes to consistent engine performance. Its durable construction reduces the need for frequent replacements, and its design may facilitate easier installation and maintenance, saving time and labor costs 4.

Installation Process

Proper installation of the Throttle Control Bracket 4009917 involves several steps to ensure it functions correctly. Begin by locating the throttle linkage and identifying the mounting points on the engine and bracket. Align the bracket with these points and secure it using the provided fasteners. Ensure that the throttle linkage is correctly attached to the bracket and that all connections are tight and secure. It is important to follow the manufacturer’s instructions to avoid common pitfalls such as improper alignment or insufficient tightening, which could lead to throttle issues 5.

Troubleshooting Common Issues

Frequent problems associated with the Throttle Control Bracket 4009917 may include throttle sticking, inconsistent engine performance, or linkage misalignment. To diagnose these issues, first, check the bracket and linkage for signs of wear or damage. Ensure that all fasteners are tight and that the throttle linkage moves freely without obstruction. If problems persist, it may be necessary to inspect other related components such as the throttle pedal or throttle body for issues 6.

Maintenance Tips

To ensure the longevity and optimal performance of the Throttle Control Bracket 4009917, regular maintenance practices are recommended. Inspect the bracket and linkage periodically for signs of wear, corrosion, or damage. Lubricate moving parts as necessary to ensure smooth operation. Additionally, keep the area around the bracket clean to prevent the accumulation of dirt and debris, which could interfere with its function 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance parts. Their product range includes engines, powertrains, and components designed to meet the demanding requirements of commercial and industrial applications 8.

Compatibility with Various Engines

The Throttle Control Bracket part 4009917 is designed to be compatible with a variety of engine models. This bracket plays a role in the operation of the throttle mechanism, ensuring that the throttle linkage is securely attached and functions correctly.

For the K19, K38, K50, and V28 engines, the bracket is engineered to fit seamlessly, providing the necessary support for the throttle linkage. These engines, known for their robust performance, benefit from the precision and durability of the Cummins-manufactured bracket.

In the case of the L10 MECHANICAL and NH/NT 855 engines, the throttle control bracket is tailored to ensure compatibility with the specific design and requirements of these engines. The bracket’s design allows for easy installation and reliable operation, enhancing the overall performance of these engines.

The M11 CELECT PLUS and M11 MECHANICAL engines also utilize the 4009917 throttle control bracket. This part plays a role in maintaining the integrity of the throttle linkage in these engines, ensuring smooth and efficient operation.

Lastly, the N14 MECHANICAL engine is another beneficiary of this bracket. The bracket’s design is optimized to fit the unique specifications of the N14 MECHANICAL engine, providing the necessary support and stability for the throttle mechanism.

The V903 engine also incorporates the 4009917 throttle control bracket. This part is essential for the proper functioning of the throttle linkage in the V903 engine, ensuring that the engine operates smoothly and efficiently.

Role of Part 4009917 Throttle Control Bracket in Engine Systems

The Throttle Control Bracket, identified by part number 4009917, is an integral component in the orchestration of various engine systems, ensuring seamless operation and optimal performance. This bracket serves as a pivotal mounting point for the throttle linkage, directly influencing the modulation of fuel delivery and engine speed.

Integration with Fuel Systems

-

Fuel Pump and Calibration: The bracket interacts with the fuel pump and calibration components, allowing precise control over fuel delivery. This ensures that the engine receives the correct amount of fuel at any given throttle position, which is essential for maintaining engine efficiency and performance 9.

-

Fuel Filter Head and Damper: By securing the throttle linkage, the bracket indirectly affects the operation of the fuel filter head and damper. Stable throttle control leads to consistent fuel flow, which is vital for the damper’s role in smoothing out fuel delivery variations 10.

-

Governor Spring Pack and Max Spring: The bracket’s role in maintaining throttle position stability is crucial for the governor spring pack and max spring functions. These springs rely on consistent throttle input to regulate engine speed and load, ensuring the engine operates within specified parameters 11.

Coordination with Pump Systems

-

Fuel and W-W Governor Pump: The throttle control bracket ensures that the fuel and W-W governor pump operates efficiently. Proper throttle modulation allows the pump to adjust fuel delivery in response to changing engine demands, enhancing overall engine responsiveness 12.

-

Fuel Pump Mounting and KV12 Uncalibrated VS: Secure throttle control provided by the bracket is essential for the stable operation of the fuel pump mounting and KV12 uncalibrated VS. This stability ensures that the pump can deliver fuel consistently, even under varying engine loads and speeds 13.

Interaction with Governor and Spring Components

-

Governor Spring Pack: The bracket’s precise control over throttle position is vital for the governor spring pack’s function. This pack relies on accurate throttle input to maintain engine speed, especially under varying load conditions 14.

-

Spring Tractor Pack: Similarly, the spring tractor pack benefits from the stable throttle control offered by the bracket. This stability ensures that the pack can effectively manage engine speed and load, contributing to smooth engine operation 15.

Role in Variable Speed Systems

-

Non-Aftercooler - Variable Speed: In variable speed engine systems, the throttle control bracket plays a significant role in modulating engine speed. By providing a stable mounting point for the throttle linkage, it ensures that the engine can respond quickly and accurately to changes in throttle position, which is essential for variable speed operation 16.

-

Pump Fuel Variable Speed: The bracket’s influence extends to the pump fuel variable speed system, where stable throttle control is necessary for the pump to adjust fuel delivery in real-time, ensuring the engine maintains optimal performance across a range of speeds 17.

Supporting On-Board Spares and Parts Base

-

Kit On Board Spares: The throttle control bracket is often included in on-board spares kits due to its essential role in engine operation. Having a spare ensures that any issues with the bracket can be quickly addressed, minimizing downtime 18.

-

Parts Base: In a parts base, the bracket is a commonly stocked item due to its importance in maintaining engine functionality. Its role in ensuring stable throttle control makes it a critical component for any engine maintenance or repair operation 19.

Conclusion

The Throttle Control Bracket part 4009917 by Cummins is a vital component in the operation of commercial truck engines. Its role in securing the throttle linkage and ensuring precise control over engine speed and power output is essential for both efficiency and drivability. With its durable construction and compatibility with various engine models, this part contributes significantly to the overall performance and reliability of commercial trucks.

References

-

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.7 CM2880 B191G, Bulletin Number 6312649.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.7 CM2880 B191G, Bulletin Number 6312649.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.7 CM2880 B191G, Bulletin Number 6312649.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.7 CM2880 B191G, Bulletin Number 6312649.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.7 CM2880 B191G, Bulletin Number 6312649.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.7 CM2880 B191G, Bulletin Number 6312649.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.