This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4364450 Throttle Valve is a component designed for use in commercial trucks. It serves a significant role in the operation of these vehicles by regulating the air and fuel mixture that enters the engine. This regulation is vital for maintaining optimal engine performance, ensuring efficient operation, and contributing to the overall reliability of the truck 1.

Basic Concepts of Throttle Valves

A throttle valve, also known as a throttle body, is a device found in an engine’s air intake system. Its primary function is to regulate the amount of air entering the engine, which in turn controls the fuel mixture. By adjusting the airflow, the throttle valve helps manage engine speed and power output. This control is crucial for the engine to operate efficiently under varying conditions and loads 2.

Purpose of the 4364450 Throttle Valve

This Cummins part plays a role in the operation of a truck by regulating engine speed and power output. It does this by controlling the airflow into the engine, which directly affects the air-fuel ratio. Proper regulation ensures that the engine runs smoothly, delivers the required power, and maintains fuel efficiency. This component is integral to the engine management system, contributing to the truck’s performance and drivability 3.

Key Features

The 4364450 Throttle Valve is designed with several features that enhance its performance. It is constructed from durable materials to withstand the harsh conditions of commercial truck operation. The valve’s design allows for precise control of airflow, ensuring accurate regulation of the air-fuel mixture. Additionally, it is engineered to integrate seamlessly with the engine’s electronic control system, providing reliable and consistent performance.

Benefits of Using the 4364450 Throttle Valve

Utilizing this part in a truck’s engine system offers several advantages. It contributes to improved engine efficiency by ensuring the optimal air-fuel ratio is maintained. This can lead to enhanced drivability, as the engine responds more effectively to changes in load and speed. Furthermore, proper regulation of the air-fuel mixture can result in potential fuel savings, making the valve a valuable component for fleet operators looking to optimize their vehicle’s performance.

Installation and Integration

Proper installation and integration of the 4364450 Throttle Valve within a truck’s engine system are important for ensuring its effective operation. The installation process should follow manufacturer guidelines to ensure compatibility with the engine’s electronic control system. Careful attention to the alignment and secure fitting of the valve is necessary to prevent air leaks and ensure accurate airflow regulation.

Troubleshooting Common Issues

Common problems associated with throttle valves can include issues with airflow regulation, leading to engine performance problems. Potential causes may range from mechanical wear to electronic control system malfunctions. Troubleshooting steps may involve inspecting the valve for physical damage, checking the electronic connections, and ensuring the valve operates within the specified parameters. Addressing these issues promptly can help maintain engine performance and reliability.

Maintenance Tips

To ensure the longevity and optimal performance of the 4364450 Throttle Valve, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the valve to remove any deposits that may affect its operation, and following the manufacturer’s guidelines for replacement schedules. Proper maintenance can help prevent issues and ensure the valve continues to function effectively.

Cummins Corporation

Cummins Corporation is a well-established manufacturer in the automotive and heavy-duty truck parts industry. With a history of producing high-quality components, Cummins has built a reputation for reliability and performance. The company’s commitment to innovation and quality is evident in its wide range of products, including the 4364450 Throttle Valve, which is designed to meet the demanding requirements of commercial truck applications.

Throttle Valve Compatibility with Cummins Engines

The Cummins Throttle Valve part number 4364450 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is engineered to work with the following engines:

GTA38 G CMEICS G116C

The GTA38 G CMEICS G116C engine benefits from the precise control provided by the Throttle Valve part 4364450. This valve ensures that the engine operates within its designed parameters, maintaining efficiency and responsiveness.

KTA19GC CM558

Similarly, the KTA19GC CM558 engine is compatible with the Throttle Valve part 4364450. This compatibility ensures that the engine’s throttle response is smooth and reliable, contributing to the overall performance and longevity of the engine.

By integrating the Throttle Valve part 4364450 into these engines, users can expect enhanced operational efficiency and a reduction in potential mechanical issues. This compatibility underscores Cummins’ commitment to providing high-quality components that meet the rigorous demands of their engine lineup.

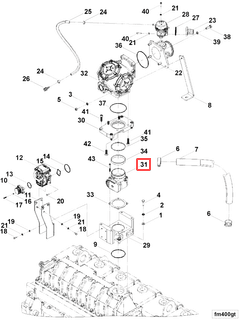

Role of Part 4364450 Throttle Valve in Engine Systems

The Throttle Valve, identified by part number 4364450, is integral to the operation of various engine systems, ensuring precise control and efficient performance. Its role is multifaceted, interacting with several key components to maintain optimal engine function.

Interaction with the Fuel Governor

The Throttle Valve works in conjunction with the Fuel Governor to regulate the fuel supply to the engine. As the throttle position changes, the valve modulates the airflow into the engine, which in turn affects the fuel demand. The Fuel Governor responds to these changes by adjusting the fuel flow, ensuring that the air-fuel mixture remains within the desired parameters for efficient combustion.

Coordination with the Fuel Control Module

In modern engine systems, the Throttle Valve is often linked to the Fuel Control Module. This module uses electronic sensors to monitor engine conditions and adjust the throttle position accordingly. The valve’s precise movement is critical for the module to maintain the correct air-fuel ratio, especially under varying load conditions.

Integration with the Governor Control Module

The Governor Control Module relies on the Throttle Valve to manage the engine’s power output. By controlling the airflow, the valve influences the engine’s RPM and torque. The module uses this information to make real-time adjustments, ensuring that the engine operates smoothly and efficiently across different operating conditions.

Role in the Overall Arrangement

Within the engine’s arrangement, the Throttle Valve is a key component that connects the air intake system to the combustion chamber. Its position directly affects the engine’s performance, making it a vital part of the overall system. The valve’s ability to quickly and accurately respond to changes in throttle position is essential for maintaining engine stability and performance.

Synergy with the Module

The Throttle Valve’s interaction with the Module is particularly important in engines that use electronic control systems. The module uses data from various sensors to determine the optimal throttle position for any given situation. The valve’s precise control is essential for the module to execute these adjustments effectively, ensuring that the engine operates at peak efficiency.

Conclusion

In summary, the Throttle Valve (part 4364450) is a pivotal component in the engine’s fuel and air management system. Its precise control and interaction with other modules and governors are essential for maintaining efficient and stable engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.