3048296

Throttle Lever

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3048296 Throttle Lever is a component designed for use in commercial trucks. It plays a role in the operation of these vehicles by allowing precise control over engine speed and power output. Understanding its function and importance can enhance both the performance and efficiency of truck operations.

Basic Concepts of Throttle Levers

A throttle lever is a mechanical or electronic device used to regulate the amount of fuel entering an engine. By adjusting the position of the throttle lever, operators can control the engine’s speed and power. This control is vital for various driving conditions, ensuring that the engine operates efficiently and effectively under different loads and speeds 1.

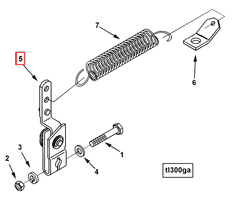

Purpose of the 3048296 Throttle Lever

The Cummins 3048296 Throttle Lever is specifically engineered to interface with the engine control system of commercial trucks. Its role is to modulate engine performance by adjusting the throttle setting. This allows for fine-tuned control over the engine’s operation, enabling drivers to match engine output to the demands of the task at hand, whether it be hauling heavy loads or navigating through varying terrain.

Key Features

The 3048296 Throttle Lever is characterized by several key features that enhance its functionality and durability. Its design incorporates high-quality materials that are resistant to wear and tear, ensuring longevity even under demanding conditions. Additionally, the lever may include ergonomic considerations for ease of use, as well as precise calibration for accurate throttle control.

Benefits

Utilizing the Cummins 3048296 Throttle Lever offers several advantages. It provides improved engine control, allowing for more efficient operation and potentially enhancing fuel efficiency. Drivers may experience a more responsive and smoother operation, contributing to a better overall driving experience. Furthermore, the precise control afforded by this throttle lever can lead to optimized performance, making it a valuable component for commercial truck applications.

Installation and Compatibility

Proper installation of the 3048296 Throttle Lever is crucial for ensuring its effective operation. Guidelines for installation should be followed carefully, including the use of any necessary tools or procedures. Compatibility with specific engine models and systems should be verified to ensure seamless integration and operation 2.

Troubleshooting and Maintenance

Common issues with the 3048296 Throttle Lever may include wear, misalignment, or electronic malfunctions. Troubleshooting steps can involve checking for physical damage, ensuring proper alignment, and verifying electronic connections. Routine maintenance practices, such as cleaning and lubrication, can help prevent issues and ensure the longevity and optimal performance of the throttle lever.

Safety Considerations

When installing, maintaining, or troubleshooting the 3048296 Throttle Lever, it is important to observe safety guidelines. This includes ensuring the engine is off and cooled down before beginning any work, using appropriate personal protective equipment, and following all manufacturer recommendations to avoid injury or damage to the component.

Compatibility with Cummins Engines

The 3048296 Throttle Lever is designed to be compatible with a range of Cummins engines, ensuring smooth and reliable operation across various applications. This throttle lever is engineered to fit seamlessly with the K19, K38, and K50 engines, providing precise control over engine speed and performance.

For the L10 MECHANICAL engine, the 3048296 throttle lever is specifically tailored to integrate with the mechanical linkage system, ensuring consistent and responsive throttle management.

The M11 CELECT PLUS and M11 MECHANICAL engines also benefit from this throttle lever, which is crafted to interface with their respective electronic and mechanical systems. This compatibility ensures that operators can maintain optimal control over engine functions, whether in demanding industrial or commercial settings.

When it comes to the N14 MECHANICAL engine, the 3048296 throttle lever is designed to work in harmony with its mechanical linkage system, providing reliable and efficient throttle operation.

Similarly, for the NH/NT 855 engine, this throttle lever is engineered to fit perfectly with the engine’s mechanical linkage, ensuring smooth and precise control over engine speed and performance.

The V28 and V903 engines also utilize the 3048296 throttle lever, which is designed to integrate with their mechanical systems, providing reliable and efficient throttle management.

Overall, the Cummins Throttle Lever part number 3048296 is a versatile and reliable component that is engineered to fit seamlessly with a range of Cummins engines, ensuring smooth and efficient operation across various applications.

Role of Part 3048296 Throttle Lever in Engine Systems

The Throttle Lever, identified by part number 3048296, is an integral component in the orchestration of various engine systems. Its primary function is to regulate the flow of fuel and air into the engine, thereby controlling the engine’s speed and power output. Here’s how it interfaces with the provided components:

-

Lever and Throttle Mechanism: The Throttle Lever is directly connected to the throttle mechanism. As the lever is moved, it adjusts the throttle plate’s position within the carburetor or fuel injection system, modulating the air-fuel mixture entering the engine.

-

Engine Mounting Parts Kit: Secure mounting of the throttle lever is essential for precise control. The engine mounting parts kit ensures that the throttle lever is correctly positioned and aligned with other components, allowing for smooth and accurate adjustments.

-

Fuel Pump and Fuel Sub 24V Pump: By controlling the throttle, the lever indirectly influences the demand on the fuel pump and the fuel sub 24V pump. As the throttle opens, more fuel is required to match the increased air intake, ensuring the engine operates efficiently across various loads.

-

Governor Kit: The governor kit works in tandem with the throttle lever to maintain a consistent engine speed under varying loads. The throttle lever’s position can be adjusted to set the desired engine speed, while the governor kit makes fine adjustments to keep the speed stable.

-

Solenoid and Mounting Valve: In systems where electronic control is employed, the throttle lever may interact with a solenoid and mounting valve. This setup allows for automated adjustments to the throttle position based on engine requirements or external inputs.

-

Vernier Throttle Control: For engines requiring fine-tuned throttle adjustments, the vernier throttle control provides micro-adjustments. The main throttle lever sets the broad range, while the vernier control allows for precise tuning within that range.

-

VT903 Short Block Kit: The throttle lever’s role becomes particularly significant in the context of the VT903 short block kit. As the core of the engine, the short block’s performance is directly influenced by the air-fuel mixture controlled by the throttle lever. Proper throttle management ensures optimal combustion, maximizing the engine’s efficiency and power output 3.

Conclusion

The Cummins 3048296 Throttle Lever is a critical component in the efficient operation of commercial trucks. Its precise control over engine speed and power output, coupled with its compatibility with a range of Cummins engines, makes it an essential part for maintaining optimal performance and efficiency in truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.