This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3056362 Throttle Lever is a component designed for use in commercial trucks, playing a significant role in the operation and performance of these vehicles. This throttle lever is integral to the engine control system, allowing for precise modulation of engine speed and power output. Understanding its function and significance can enhance both the maintenance and operational efficiency of commercial trucks 1.

Basic Concepts of Throttle Levers

A throttle lever is a mechanical or electronic device used to control the amount of fuel entering an engine, thereby regulating its speed and power output. In an engine system, the throttle lever interfaces with various components to adjust the airflow into the engine, which directly influences performance. By moving the throttle lever, the driver can increase or decrease engine RPM, affecting the truck’s acceleration, cruising speed, and overall power delivery 2.

Purpose of the Cummins 3056362 Throttle Lever

The Cummins 3056362 Throttle Lever is specifically designed to interface with the engine control system of commercial trucks. Its role is to provide the driver with a means to modulate engine performance by adjusting the fuel and air mixture entering the engine. This modulation allows for precise control over the truck’s speed and power, enhancing both drivability and efficiency. The lever works in conjunction with the engine’s electronic control unit (ECU) to ensure smooth and responsive engine operation 3.

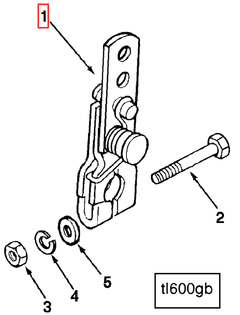

Key Features

The Cummins 3056362 Throttle Lever is characterized by its robust design and high-quality materials, ensuring durability and reliable performance. Key features include a precision-machined lever arm for accurate control, corrosion-resistant materials to withstand harsh operating environments, and a secure mounting system for stable operation. These features contribute to the lever’s functionality and longevity, making it a reliable component for commercial truck applications.

Benefits

The use of the Cummins 3056362 Throttle Lever offers several advantages. It provides improved engine control, allowing for more precise modulation of engine speed and power. This can lead to an enhanced driver experience, with smoother acceleration and deceleration. Additionally, proper throttle control can contribute to increased fuel efficiency and overall engine performance, making it a valuable component for commercial truck operators.

Installation and Integration

Installing the Cummins 3056362 Throttle Lever involves several steps to ensure proper integration with the truck’s engine control system. Compatibility with various truck models and engine types must be considered, along with the integration of the lever with the existing ECU. Careful attention to manufacturer guidelines during installation is crucial to ensure optimal performance and safety.

Troubleshooting Common Issues

Common issues with throttle levers may include unresponsiveness, sticking, or inaccurate engine speed control. These problems can often be traced to mechanical wear, contamination, or electrical faults. Troubleshooting steps may involve inspecting the lever for physical damage, cleaning or lubricating moving parts, and checking electrical connections for integrity. Addressing these issues promptly can help maintain engine performance and reliability.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3056362 Throttle Lever, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the lever and its components to remove dirt and debris, and ensuring all connections are secure and free from corrosion. Following these maintenance practices can help prevent issues and extend the service life of the throttle lever.

Safety Considerations

When working with the throttle lever, it is important to follow safety practices to prevent accidents and ensure reliable performance. This includes proper handling during installation or maintenance, adhering to manufacturer guidelines, and taking operational safety measures to avoid unintended engine acceleration. Ensuring the throttle lever is correctly installed and maintained is crucial for safe and efficient truck operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and performance is evident in its wide range of engine components, including the Cummins 3056362 Throttle Lever, which is designed to meet the demanding requirements of commercial truck applications.

Throttle Lever Part 3056362 Compatibility with Cummins Engines

The Cummins Throttle Lever part number 3056362 is designed to integrate seamlessly with a variety of Cummins engine models. This part is essential for controlling the engine’s throttle, ensuring smooth operation and efficient performance. Below is a detailed look at the compatibility of this throttle lever with specific Cummins engines.

K19, K38, and K50 Series

The Throttle Lever part 3056362 is compatible with the K19, K38, and K50 series engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The throttle lever’s design ensures precise control over the engine’s power output, making it ideal for these demanding environments.

KTA38GC CM558

The KTA38GC CM558 engine also benefits from the Throttle Lever part 3056362. This engine is part of Cummins’ lineup of advanced diesel engines, offering high performance and efficiency. The throttle lever’s integration with the KTA38GC CM558 ensures that operators can maintain optimal control over the engine’s throttle, enhancing overall performance and reliability.

Compatibility Summary

- K19 Series: The throttle lever is engineered to fit the K19 engine, providing precise control and enhancing the engine’s operational efficiency.

- K38 Series: Similarly, the K38 engine is designed to work with the 3056362 throttle lever, ensuring smooth and reliable performance.

- K50 Series: The K50 engine also integrates well with this throttle lever, offering operators the control needed for heavy-duty applications.

- KTA38GC CM558: This advanced engine model benefits from the precise control offered by the 3056362 throttle lever, ensuring optimal performance and efficiency.

Role of Part 3056362 Throttle Lever in Engine Systems

The 3056362 Throttle Lever is an integral component in the regulation and control of engine performance. It operates in conjunction with several other components to ensure smooth and efficient engine operation.

Interaction with the Throttle

The primary function of the 3056362 Throttle Lever is to modulate the position of the throttle. This lever is directly connected to the throttle, which controls the amount of air entering the engine. By adjusting the throttle position, the lever directly influences the engine’s power output and RPM.

Coordination with the Rocker

In many engine systems, the 3056362 Throttle Lever works in tandem with a rocker mechanism. The rocker amplifies the movement of the throttle lever, allowing for more precise control over the throttle’s opening and closing. This interaction ensures that even small adjustments to the lever result in significant changes to the engine’s air intake, facilitating fine-tuned performance adjustments.

Lever Mechanisms

The 3056362 Throttle Lever often interacts with other lever mechanisms within the engine system. These levers may include linkage levers that connect to the carburetor or fuel injection system. The coordination between these levers ensures that the engine receives the correct air-fuel mixture based on the driver’s input via the throttle lever.

Overall System Integration

In a comprehensive engine system, the 3056362 Throttle Lever is part of a larger network that includes sensors, actuators, and control units. These components work together to monitor and adjust engine performance in real-time. The throttle lever’s position is often monitored by sensors that send data to the engine control unit (ECU), which makes further adjustments to optimize performance and efficiency.

By understanding how the 3056362 Throttle Lever fits into these systems, engineers and mechanics can better diagnose issues, perform maintenance, and make modifications to enhance engine performance.

Conclusion

The Cummins 3056362 Throttle Lever is a critical component in the engine control system of commercial trucks. Its precise modulation of engine speed and power output enhances drivability, efficiency, and overall performance. Understanding its function, installation, maintenance, and integration with various Cummins engines is essential for optimal operation and longevity of the component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.