This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2886671 Variable Timing Supply Tube is a component designed to enhance the operation of heavy-duty trucks. Its purpose is to facilitate the variable timing system within the engine, allowing for optimized performance under various driving conditions. This tube plays a role in ensuring that the engine operates efficiently, contributing to overall vehicle performance and reliability 1.

Function and Operation

The Variable Timing Supply Tube operates by delivering pressurized oil to the variable timing mechanism within the engine. This mechanism adjusts the timing of the camshaft in relation to the crankshaft, allowing the engine to adapt to different loads and speeds. The tube interacts with the engine’s lubrication system, ensuring a consistent supply of oil to the variable timing actuator. This interaction is vital for the precise operation of the variable timing system, which in turn affects engine performance, fuel efficiency, and emissions 2.

Key Features

The Cummins 2886671 is characterized by several key features. It is constructed from durable materials to withstand the high pressures and temperatures within the engine compartment. The design incorporates advanced engineering to ensure a secure fit and reliable operation. Additionally, the tube may feature specific technological advancements, such as enhanced sealing mechanisms, to prevent oil leaks and maintain system integrity 3.

Benefits

The incorporation of the Variable Timing Supply Tube into the engine system offers several advantages. It contributes to improved engine performance by enabling more precise control over the variable timing mechanism. This results in better fuel efficiency, as the engine can operate more efficiently across a range of conditions. Furthermore, the optimized operation of the variable timing system can lead to a reduction in emissions, aligning with environmental regulations and promoting sustainable operation 4.

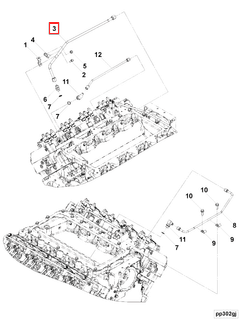

Installation Process

Installing the Cummins 2886671 requires careful attention to detail. The process begins with ensuring the engine is cool and the lubrication system is properly drained to prevent contamination. The old tube should be removed, taking care not to damage surrounding components. The new tube is then installed, ensuring all connections are secure and properly sealed. It is important to follow the manufacturer’s guidelines to avoid potential challenges such as oil leaks or improper fitting.

Maintenance and Troubleshooting

Regular maintenance of the Variable Timing Supply Tube is important to ensure optimal performance and longevity. This includes checking for signs of wear or damage, ensuring all connections are tight, and monitoring the engine’s oil pressure to detect any issues with the lubrication system. Common issues may include oil leaks or reduced engine performance, which can often be traced back to the variable timing system. Troubleshooting methods may involve inspecting the tube and its connections, as well as testing the variable timing actuator for proper operation.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the automotive industry, particularly in the heavy-duty truck sector, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes engines and components designed to meet the demanding requirements of commercial vehicles, ensuring reliable performance and efficiency.

Cummins Variable Timing Supply Tube Part 2886671 Compatibility

The Cummins Variable Timing Supply Tube, part number 2886671, is designed to integrate seamlessly with a range of engine models. This part is important for maintaining the precise timing necessary for optimal engine performance. Here’s how it fits with specific Cummins engines:

VTA903 and CM2250 Engines

The VTA903 and CM2250 engines both benefit from the Variable Timing Supply Tube. This component ensures that the oil flow to the variable timing mechanism is consistent and unhindered, which is essential for the engines’ timing systems to operate correctly. The design of the tube allows for smooth oil passage, reducing wear and enhancing longevity.

V105 Engine

The V105 engine also utilizes the Variable Timing Supply Tube. In this engine, the tube plays a role in managing the oil supply to the variable timing actuator. This ensures that the engine can adjust its timing dynamically, which is important for performance and efficiency. The tube’s precision engineering guarantees that the oil reaches the actuator without restriction, maintaining the engine’s timing accuracy.

Grouping for Clarity

When considering the VTA903 and CM2250 engines, it’s worth noting that both are part of Cummins’ lineup of high-performance engines. They share similar design philosophies and engineering principles, which is why the Variable Timing Supply Tube fits both models so well. The V105 engine, while distinct in its applications, also relies on the same fundamental design of the tube to ensure its variable timing system functions flawlessly.

Role of Part 2886671 Variable Timing Supply Tube in Engine Systems

The Variable Timing Supply Tube, identified as part 2886671, is integral to the synchronization and efficiency of various engine components. Its primary function is to regulate the timing of the engine’s valve operation, which directly influences the performance of other key components.

Interaction with Connecting Rod and Piston

The Variable Timing Supply Tube works in concert with the connecting rod and piston assembly. By ensuring precise valve timing, it optimizes the air-fuel mixture entering the combustion chamber. This optimization enhances the efficiency of the piston’s movement, allowing for smoother and more powerful strokes. The tube’s role in maintaining consistent timing reduces the likelihood of misfires and improves overall engine performance.

Coordination with Injector

In conjunction with the injector, the Variable Timing Supply Tube plays a role in fuel delivery and combustion efficiency. Proper valve timing ensures that the injector releases fuel at the optimal moment, maximizing combustion efficiency and reducing emissions. This synergy between the tube and the injector leads to better fuel economy and enhanced engine responsiveness.

Overall Engine Harmony

The Variable Timing Supply Tube’s ability to fine-tune valve timing contributes to the harmonious operation of the engine’s moving parts. It ensures that each component, from the connecting rod and piston to the injector, operates in perfect synchrony. This coordination is essential for achieving peak performance, reliability, and longevity in engine systems.

Conclusion

The Cummins 2886671 Variable Timing Supply Tube is a critical component in the operation of heavy-duty engines, ensuring efficient and reliable performance. Its role in the variable timing system allows for optimized engine operation across various conditions, contributing to improved fuel efficiency and reduced emissions. Proper installation, maintenance, and understanding of its compatibility with specific engine models are essential for maximizing the benefits of this Cummins part.

-

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.