This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

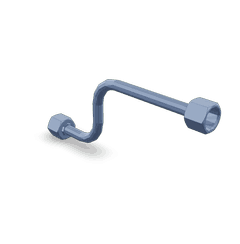

The Variable Timing Supply Tube (Part #3090383) manufactured by Cummins is a component designed to facilitate the operation of variable valve timing systems in heavy-duty trucks. This part is integral to the efficient functioning of the engine, contributing to performance, fuel efficiency, and emissions control 3.

Basic Concepts of Variable Timing Supply Tube

Variable valve timing systems adjust the timing of the valve operation to optimize engine performance across a range of operating conditions. The Variable Timing Supply Tube is a key component in these systems, responsible for delivering pressurized oil to the variable valve timing actuator. This pressurized oil enables the actuator to change the position of the camshaft, thereby altering valve timing 1.

Function and Operation

The Variable Timing Supply Tube operates by channeling pressurized oil from the engine’s lubrication system to the variable valve timing actuator. This process allows the actuator to adjust the camshaft’s position, which in turn modifies the timing of the valve events. The tube interacts with other components such as the oil pump, filter, and various sensors to ensure precise oil delivery and system operation 2.

Purpose of the Variable Timing Supply Tube

The Variable Timing Supply Tube plays a role in enhancing engine performance by enabling the variable valve timing system to adjust valve timing for optimal power and efficiency. It contributes to improved fuel efficiency by allowing the engine to operate more efficiently under varying conditions. Additionally, it aids in emissions control by ensuring that the engine runs cleaner through precise valve timing 3.

Key Features

The design and construction of the Variable Timing Supply Tube include features that enhance its functionality and durability. These features may include high-quality materials resistant to wear and corrosion, precise engineering to ensure accurate oil flow, and robust connections to withstand the pressures and temperatures within the engine compartment 1.

Benefits

The Variable Timing Supply Tube offers several advantages. It contributes to improved engine efficiency by enabling the variable valve timing system to operate effectively. This results in better fuel economy and reduced emissions. Additionally, it enhances drivability by allowing the engine to respond more smoothly to changes in operating conditions 3.

Installation and Compatibility

Proper installation of the Variable Timing Supply Tube involves following manufacturer guidelines to ensure it is correctly positioned and connected within the engine’s lubrication system. Compatibility with various Cummins engine models should be verified to ensure optimal performance and integration with the variable valve timing system 2.

Maintenance and Troubleshooting

Routine maintenance practices for the Variable Timing Supply Tube include regular inspections for signs of wear, leaks, or damage. Troubleshooting may involve checking for proper oil pressure and flow, ensuring connections are secure, and verifying the functionality of the variable valve timing system. These practices help maintain the tube’s performance and longevity 1.

Common Issues and Solutions

Frequent problems associated with the Variable Timing Supply Tube may include oil leaks, blockages, or damage to the tube itself. Suggested solutions or replacement procedures should follow manufacturer recommendations to address these issues effectively and restore the variable valve timing system’s functionality 2.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and technological advancements contribute to its leadership in the power generation and transportation sectors 3.

Cummins Engine Compatibility with Variable Timing Supply Tube Part 3090383

The Variable Timing Supply Tube part number 3090383, manufactured by Cummins, is a critical component in the engine’s timing system. This part is designed to ensure the proper flow of oil to the variable timing mechanism, which is essential for the engine’s performance and efficiency 3.

QSK19 CM500 Engines

The QSK19 CM500 engine series is a high-performance, heavy-duty diesel engine known for its reliability and power. The Variable Timing Supply Tube part 3090383 fits seamlessly into this engine series by providing a precise and uninterrupted oil supply to the variable timing actuator. This ensures that the engine can adjust its timing dynamically, optimizing performance and fuel efficiency across a wide range of operating conditions 1.

Grouping of Engines

The Variable Timing Supply Tube part 3090383 is compatible with various Cummins engines that utilize similar variable timing systems. These engines often share common design principles and components, making the part interchangeable across different models. By ensuring compatibility with a range of engines, Cummins maintains a streamlined supply chain and simplifies maintenance and repair processes for technicians and operators 2.

Role of Part 3090383 Variable Timing Supply Tube in Engine Systems

The Variable Timing Supply Tube, identified by part number 3090383, is integral to the operation of several key components within modern engine systems. Its primary function is to deliver pressurized fluid, typically oil, to the Variable Valve Timing (VVT) system. This ensures that the VVT mechanism operates smoothly and efficiently, allowing for optimal valve timing adjustments based on engine load and speed 3.

Integration with Engine Components

-

Variable Valve Timing (VVT) System: The Variable Timing Supply Tube is directly connected to the VVT system. It supplies the necessary hydraulic pressure to the VVT actuators, enabling precise control over valve timing. This enhances engine performance by improving fuel efficiency and reducing emissions 1.

-

Engine Performance: By ensuring consistent and reliable hydraulic pressure to the VVT system, the Variable Timing Supply Tube plays a significant role in maintaining engine performance. It allows the engine to adapt to varying driving conditions, resulting in smoother acceleration and better overall drivability 3.

-

Plumbing Network: The Variable Timing Supply Tube is part of the engine’s plumbing network, which includes various hoses, pipes, and connectors. It interfaces with the oil pump and other hydraulic components, ensuring a seamless flow of pressurized oil throughout the system. Proper maintenance of this network is essential for the longevity and efficiency of the engine 2.

-

Fuel Injectors: Although the Variable Timing Supply Tube does not directly interact with fuel injectors, its role in maintaining optimal engine performance indirectly supports the efficient operation of these components. Proper valve timing, facilitated by the VVT system, ensures that fuel is injected at the most effective moments, enhancing combustion efficiency and overall engine output 3.

Conclusion

In summary, the Variable Timing Supply Tube (part 3090383) is a vital component that supports the VVT system, enhances engine performance, and integrates seamlessly within the engine’s plumbing network. Its reliable operation is essential for the efficient functioning of various engine components, including fuel injectors 3.

-

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ ↩ ↩ ↩ ↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ ↩ ↩ ↩ ↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.