This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3972912 Timing Lock O-Ring is a specialized component designed for use in commercial truck engines. It ensures the precise alignment of engine components during maintenance or repair procedures. This part plays a role in maintaining the operational integrity of the engine by facilitating accurate timing adjustments.

Basic Concepts of Timing Lock O-Rings

A timing lock O-ring is a sealing component used in engine maintenance to hold specific parts in place, ensuring they do not move during the repair process. This function is vital for the accurate reassembly of the engine, as proper timing is important for the engine’s performance and reliability. The O-ring creates a seal that prevents fluid leaks and maintains the integrity of the engine’s timing system 1.

Role of the 3972912 Timing Lock O-Ring in Truck Operation

The Cummins 3972912 Timing Lock O-Ring is specifically designed to interact with various engine components, ensuring they remain in the correct position during maintenance. This part is instrumental in the timing adjustment process, which is an important aspect of engine operation. By securing components in place, the O-ring allows for precise reassembly, which in turn contributes to the engine’s overall performance and longevity.

Key Features of the 3972912 Timing Lock O-Ring

The Cummins 3972912 Timing Lock O-Ring is crafted from high-quality materials to ensure durability and reliability. Its design specifications are tailored to fit specific Cummins engine models, providing a secure and effective seal. The O-ring’s unique characteristics, such as its elasticity and resistance to wear, enhance its performance and contribute to the engine’s efficient operation.

Benefits of Using the 3972912 Timing Lock O-Ring

Utilizing the Cummins 3972912 Timing Lock O-Ring offers several advantages. It contributes to improved engine efficiency by ensuring accurate timing during maintenance. Additionally, it reduces the need for frequent maintenance by providing a reliable seal that prevents leaks. The enhanced durability of the O-ring also means it can withstand the rigors of commercial truck operation, leading to longer-lasting engine components 2.

Installation and Maintenance Guidelines

Proper installation of the Cummins 3972912 Timing Lock O-Ring is important for its effective performance. It should be carefully placed according to the manufacturer’s instructions to ensure a secure fit. Regular maintenance checks are recommended to verify the O-ring’s condition and integrity. If any signs of wear or damage are detected, the O-ring should be replaced promptly to maintain engine performance.

Troubleshooting Common Issues

Common issues with the Cummins 3972912 Timing Lock O-Ring may include leaks, wear, or failure symptoms. Identifying these problems early is important for maintaining engine efficiency. Leaks can often be traced to a compromised O-ring, while wear may indicate the need for replacement. Addressing these issues promptly can prevent more significant engine problems and ensure continued reliable operation.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its high-quality engines and components. With a rich history and a diverse product range, Cummins has established a strong reputation for reliability and performance. The company’s commitment to innovation and excellence is reflected in its products, including the Cummins 3972912 Timing Lock O-Ring 3.

Role of Part 3972912 Timing Lock O-Ring in Engine Systems

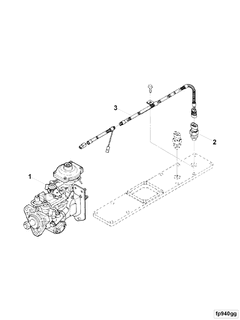

The Timing Lock O-Ring, identified by part number 3972912, is instrumental in ensuring the precise synchronization of various engine components. Its application is particularly significant in systems involving the fuel injection pump and the fuel pump.

In the context of the fuel injection pump, the Timing Lock O-Ring plays a key role in maintaining the integrity of the timing mechanism. This ensures that the fuel is injected into the combustion chamber at the exact moment required for optimal engine performance. The O-ring seals the timing components, preventing any fuel leakage that could disrupt the timing and lead to inefficient combustion.

Similarly, in the fuel pump system, the Timing Lock O-Ring is essential for maintaining the seal around timing gears or sprockets. This is vital for the consistent delivery of fuel under pressure. The O-ring’s sealing properties are fundamental in preventing fuel leaks, which could otherwise result in a loss of pressure and inefficient fuel delivery to the engine.

Furthermore, in general pump systems within the engine, the Timing Lock O-Ring ensures that the timing of the pump’s operation is maintained. This is important for the synchronized operation of the engine’s fuel system, contributing to smooth and reliable engine performance.

Overall, the Timing Lock O-Ring (part 3972912) is a component that, while small in size, plays a significant role in the efficient and reliable operation of engine systems involving fuel injection and pumping. Its proper installation and maintenance are key to ensuring the engine operates within its designed parameters.

Conclusion

The Cummins 3972912 Timing Lock O-Ring is a critical component in the maintenance and operation of commercial truck engines. Its role in ensuring precise timing and sealing of engine components contributes significantly to the engine’s performance, reliability, and longevity. Proper installation, regular maintenance, and prompt troubleshooting of issues are essential practices to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.