This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

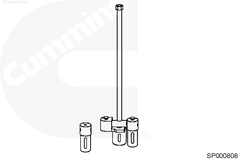

The Cummins 3375623 Check Tapping Guide Tool is a specialized instrument designed for use in the maintenance and repair of heavy-duty trucks. This tool is integral to ensuring the precision and accuracy of engine component checks and adjustments, contributing to the overall efficiency and reliability of truck maintenance procedures.

Purpose and Functionality

The Cummins 3375623 Check Tapping Guide Tool serves a specific role in the maintenance and repair processes of heavy-duty trucks. It is designed to assist mechanics in performing precise checks and adjustments on engine components. By providing a stable and accurate reference point, this tool helps in ensuring that adjustments are made with the required precision, which is vital for the optimal performance and longevity of the engine 1.

Key Features

The Cummins 3375623 Check Tapping Guide Tool is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear and tear, ensuring longevity even under demanding conditions. The tool is engineered to provide a stable platform for accurate measurements and adjustments, with features that allow for easy handling and precise positioning 2.

Benefits

Utilizing the Cummins 3375623 Check Tapping Guide Tool offers several advantages. It improves the accuracy of engine component checks, which is crucial for maintaining engine performance. Additionally, it can reduce the time required for maintenance procedures, allowing mechanics to complete tasks more efficiently. The tool also enhances safety by providing a secure and stable platform for adjustments, minimizing the risk of injury to the mechanic 3.

Application in Truck Maintenance

The Cummins 3375623 Check Tapping Guide Tool is employed in various maintenance procedures for heavy-duty trucks. It is particularly useful in valve adjustments, where precision is paramount to ensure proper engine function. The tool is also utilized in cylinder head inspections and other critical engine checks, providing a reliable reference point for accurate measurements and adjustments 4.

Troubleshooting and Maintenance

Common issues with the Cummins 3375623 Check Tapping Guide Tool may include wear on the contact surfaces or misalignment. Troubleshooting steps involve inspecting the tool for any signs of damage or wear and ensuring that it is properly aligned during use. Regular maintenance practices, such as cleaning and checking for wear, can help ensure the tool’s longevity and effectiveness 5.

Safety Considerations

When using the Cummins 3375623 Check Tapping Guide Tool, it is important to observe certain safety practices. This includes ensuring that the engine is properly secured and that all safety protocols are followed to protect both the user and the equipment. Proper handling and storage of the tool are also important to maintain its condition and ensure safe operation.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the diesel engine and power generation markets. The company’s product range includes engines, filtration, emissions solutions, and power systems, all designed to meet the demanding requirements of various industries.

Conclusion

The Cummins 3375623 Check Tapping Guide Tool is an essential component in the maintenance and repair of heavy-duty trucks. Its precise functionality, durable design, and the benefits it offers in terms of accuracy, efficiency, and safety make it a valuable tool for mechanics. Regular maintenance and proper use of this Cummins part ensure its effectiveness and longevity, contributing to the overall reliability and performance of truck engines.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B4.5 CM2350 B147B Stop-Start Applications. Bulletin Number 5411253.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.