This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

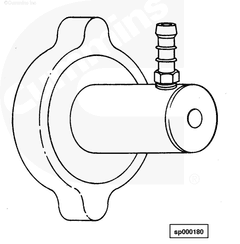

The Tool, Blow-by Checking (Part #3376949) is a specialized instrument manufactured by Cummins to facilitate the measurement of blow-by in heavy-duty truck engines. This Cummins part is designed to assist technicians in diagnosing and assessing the condition of engine components, ensuring optimal performance and longevity of the engine.

Basic Concepts of Blow-by and Its Measurement

Blow-by refers to the leakage of combustion gases past the piston rings into the crankcase of an internal combustion engine. This phenomenon occurs due to the pressure differential between the combustion chamber and the crankcase. Blow-by can have several implications for engine performance, including reduced efficiency, increased oil contamination, and higher emissions 1. Measuring blow-by is a process in maintaining engine health, as it provides insights into the condition of piston rings, cylinder walls, and overall engine seal integrity.

Purpose and Functionality of the Tool, Blow-by Checking

The Tool, Blow-by Checking is specifically designed to diagnose and measure blow-by in Cummins engines. By quantifying the amount of blow-by, technicians can assess the effectiveness of piston rings, the condition of cylinder walls, and the overall seal integrity of the engine. This tool aids in identifying potential issues early, allowing for timely maintenance and repairs to prevent more significant engine damage.

Key Features of the Tool, Blow-by Checking

The Tool, Blow-by Checking is engineered with several key features to ensure accurate and reliable measurements. Its design incorporates high-quality materials that withstand the rigors of engine environments. Ergonomic considerations are integrated into the tool’s construction to enhance ease of use, allowing technicians to perform measurements efficiently. Additionally, the tool may include technological advancements such as precise measurement sensors and user-friendly interfaces to streamline the diagnostic process.

Benefits of Using the Tool, Blow-by Checking

Utilizing the Tool, Blow-by Checking in routine engine maintenance and diagnostics offers several advantages. It contributes to prolonging engine life by enabling early detection of wear and tear on critical components. Improved fuel efficiency can be achieved through the identification and rectification of blow-by issues, leading to cost savings over time 2. Furthermore, reducing blow-by helps lower emissions, aligning with environmental regulations and promoting sustainable engine operation.

Troubleshooting and Maintenance Suggestions

When using the Tool, Blow-by Checking, technicians may encounter common issues such as inaccurate readings or tool malfunctions. Addressing these issues promptly is vital to ensure the tool’s effectiveness. Regular maintenance of the tool, including cleaning and calibration checks, is recommended to maintain its accuracy and reliability over time. Following manufacturer guidelines for use and care will help maximize the tool’s performance and longevity.

Cummins: A Brief Overview

Cummins Inc. is a global leader in the diesel engine industry, known for its innovative solutions and commitment to quality. With a rich history of providing reliable and efficient engines, Cummins serves a wide range of industries, including heavy-duty trucking. Diagnostic tools like the Tool, Blow-by Checking play a significant role in Cummins’ product ecosystem, supporting technicians in maintaining and optimizing engine performance. Cummins’ dedication to innovation and customer satisfaction underscores the importance of such tools in ensuring the reliability and efficiency of their engines.

Conclusion

The Tool, Blow-by Checking (Part #3376949) is an essential diagnostic tool for maintaining Cummins engines. By accurately measuring blow-by, technicians can ensure the optimal performance and longevity of heavy-duty truck engines. Regular use of this part in maintenance routines can lead to improved fuel efficiency, reduced emissions, and early detection of engine issues, ultimately contributing to the overall reliability and efficiency of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.