This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

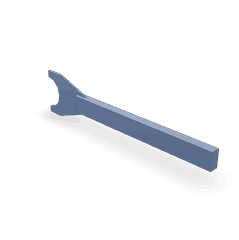

The Cummins Tool, Manufacturer Jump Tube Removal (Part #3823819), is a specialized instrument designed for the maintenance and repair of heavy-duty trucks. This Cummins part is specifically engineered to assist in the removal and installation of jump tubes in diesel engines, with a particular focus on those manufactured by Cummins. Its role in streamlining maintenance procedures makes it a valuable asset for fleet operators and maintenance professionals.

Purpose and Functionality

The Tool, Manf Jump Tube Rem serves a pivotal role in the maintenance of diesel engines by facilitating the removal and installation of jump tubes. These components are integral to the engine’s operation, and their proper maintenance is essential for ensuring optimal engine performance. The tool is designed to make these procedures more efficient and less labor-intensive, thereby reducing the time and effort required for maintenance tasks 1.

Key Features

The Tool, Manf Jump Tube Rem is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that ensure resilience under the demanding conditions of heavy-duty truck maintenance. Unique attributes of the tool, such as its ergonomic handle and precision-machined components, contribute to its effectiveness in performing its intended function. These features not only improve the tool’s performance but also extend its lifespan, making it a reliable choice for maintenance professionals 2.

Benefits

Utilizing the Tool, Manf Jump Tube Rem offers several advantages. It significantly improves the efficiency of maintenance procedures by simplifying the removal and installation of jump tubes. This efficiency translates into reduced maintenance time, allowing fleet operators to minimize downtime and maximize operational uptime. Additionally, the tool enhances safety during repair procedures by providing a secure and controlled method for handling jump tubes, thereby reducing the risk of injury to maintenance personnel. The long-term benefits for fleet operators include increased productivity, lower maintenance costs, and improved engine reliability 3.

Troubleshooting and Maintenance

To ensure the optimal performance and longevity of the Tool, Manf Jump Tube Rem, it is important to address common issues that may arise during its use. Regular maintenance, including cleaning and periodic inspections, is recommended to prevent malfunctions and extend the tool’s lifespan. Proper storage in a dry, secure location protects the tool from damage and corrosion. Following these maintenance practices ensures that the tool remains in excellent working condition, ready for use when needed.

Application in Truck Maintenance

The Tool, Manf Jump Tube Rem is an integral component of comprehensive truck maintenance routines. Its compatibility with various Cummins engine models makes it a versatile tool for fleet operators. Incorporating this tool into regular maintenance schedules allows for more efficient and effective engine maintenance, contributing to the overall reliability and performance of heavy-duty trucks. Best practices for using the tool include following manufacturer guidelines for its application and ensuring that maintenance personnel are trained in its proper use.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its diesel engines and related components. With a rich history of innovation and a commitment to quality and customer satisfaction, Cummins has established itself as a leader in the field. The company’s product offerings include a wide range of engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ dedication to excellence is reflected in its reputation for producing reliable, high-performance products that are trusted by fleet operators worldwide.

Conclusion

The Tool, Manf Jump Tube Rem (Part #3823819) is a critical tool for the maintenance and repair of Cummins diesel engines in heavy-duty trucks. Its design, functionality, and benefits make it an indispensable asset for fleet operators and maintenance professionals. By incorporating this tool into regular maintenance routines and adhering to best practices for its use and maintenance, operators can ensure the optimal performance and reliability of their vehicles.

-

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.