This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

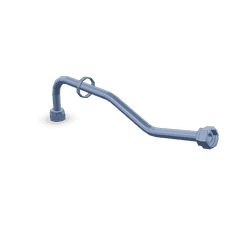

The Corrosion Resistor Tube, part number 3008792, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the industry, produces a range of parts and systems aimed at enhancing the performance and longevity of commercial vehicles. This part is specifically engineered to address the challenges posed by corrosive environments commonly encountered in trucking operations.

Basic Concepts of Corrosion Resistor Tubes

Corrosion resistor tubes are components designed to protect various parts of a truck from the damaging effects of corrosion. These tubes are typically made from materials that resist corrosion, such as stainless steel or coated metals. Their function is to provide a barrier between the corrosive elements and the truck’s components, thereby extending the lifespan of the vehicle and reducing maintenance costs 1. In the context of a truck, these tubes play a role in safeguarding critical systems and components from environmental factors that could lead to corrosion.

Purpose of the 3008792 Corrosion Resistor Tube

The 3008792 Corrosion Resistor Tube is designed to protect specific areas within a truck’s system from corrosion. Its placement is strategic, targeting components that are particularly vulnerable to corrosive damage. By doing so, it helps maintain the integrity and efficiency of the truck’s systems, ensuring that they operate as intended without the premature degradation that corrosion can cause.

Key Features

The 3008792 Corrosion Resistor Tube boasts several key features that enhance its performance. It is constructed from high-quality materials that offer superior resistance to corrosion. The design of the tube includes precise dimensions and fittings to ensure a secure and effective installation. Additionally, it may feature unique characteristics such as a protective coating or specialized threading to further enhance its durability and effectiveness in corrosive environments.

Benefits

The use of the 3008792 Corrosion Resistor Tube offers several benefits. It provides improved durability for the components it protects, enhancing the overall reliability of the truck. By offering enhanced protection against corrosion, it helps reduce the frequency of maintenance and repair needs. Over time, this can lead to potential cost savings for fleet operators, as the need for replacements and repairs decreases 2.

Installation Process

Installing the 3008792 Corrosion Resistor Tube requires careful attention to detail to ensure its effectiveness. The process begins with preparing the area where the tube will be installed, ensuring it is clean and free from any existing corrosion. The necessary tools for installation include wrenches and possibly a torque wrench to ensure proper tightening of fittings. Following the manufacturer’s guidelines for installation is crucial to achieve a secure and effective integration into the truck’s system.

Troubleshooting Common Issues

Common issues with the 3008792 Corrosion Resistor Tube may include leaks or a reduction in its effectiveness over time. Troubleshooting these problems involves inspecting the tube and its connections for signs of damage or wear. Solutions may range from tightening loose connections to replacing the tube if it has been compromised. Regular inspections can help identify potential issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 3008792 Corrosion Resistor Tube, regular maintenance is recommended. This includes periodic inspections to check for any signs of corrosion or damage. Cleaning the tube and its surroundings can also help prevent the buildup of corrosive substances. Following these maintenance practices can help maintain the tube’s effectiveness and contribute to the overall reliability of the truck.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and its focus on reliability and performance make it a preferred choice for commercial vehicle operators worldwide.

Corrosion Resistor Tube for Cummins Engines

The Corrosion Resistor Tube, part number 3008792, is a critical component in the maintenance and longevity of certain Cummins engines. This part is specifically designed to combat the effects of corrosion, which can significantly degrade engine performance and lifespan.

N14 MECHANICAL

In the N14 MECHANICAL engine, the Corrosion Resistor Tube is integral to the cooling system. It is typically used in the exhaust system to protect against the corrosive effects of exhaust gases. This tube ensures that the engine’s exhaust components remain intact and functional, thereby maintaining the overall efficiency and reliability of the engine.

NH/NT 855

Similarly, in the NH/NT 855 engines, the Corrosion Resistor Tube plays a vital role in protecting the exhaust system from corrosion. Given the high temperatures and corrosive nature of exhaust gases, this tube is essential for preventing damage to the exhaust manifold and other related components. Its placement in the exhaust system ensures that the engine operates smoothly and efficiently over an extended period.

By integrating the Corrosion Resistor Tube into the exhaust systems of these engines, Cummins ensures that the engines remain protected against the harsh conditions they are subjected to during operation. This proactive approach to maintenance helps in extending the engine’s life and reducing the need for frequent repairs.

Role of Part 3008792 Corrosion Resistor Tube in Engine Systems

The part 3008792 Corrosion Resistor Tube is integral to the efficient operation of various engine systems. It is designed to withstand harsh environments and resist corrosion, ensuring longevity and reliability in its applications.

Integration with Engine Components

-

Corrosion Resistor Mounting: The tube is often mounted using a corrosion resistor mounting system. This setup ensures that the tube remains securely in place while operating under high stress and temperature conditions. The mounting system is designed to accommodate the tube’s specific dimensions and weight, providing a stable foundation.

-

Filter Mounting: In systems where filtration is necessary, the corrosion resistor tube is frequently integrated with filter mounting components. This allows for the efficient flow of fluids or gases through the system while maintaining the integrity of the filter media. The tube’s corrosion-resistant properties help prevent contamination and ensure that the filter operates effectively over time.

-

Resistor: The tube itself acts as a resistor within the engine system, regulating the flow of substances and withstanding electrical currents where applicable. Its resistance properties help in maintaining consistent performance and protecting other sensitive components from potential damage.

-

Corrosion Protection: The primary function of the tube is to offer superior corrosion protection. In environments where exposure to corrosive agents is high, the tube helps in preserving the structural integrity of the engine components it is connected to. This protection is vital for the sustained operation of the engine system.

-

Resistor Corrosion: By resisting corrosion, the tube plays a significant role in preventing the degradation of other components. Its durable construction ensures that it can operate effectively even in the presence of corrosive substances, thereby extending the lifespan of the entire engine system.

Conclusion

In summary, the part 3008792 Corrosion Resistor Tube is a key component in enhancing the durability and efficiency of engine systems. Its integration with various mounting and filtration components ensures that it contributes significantly to the overall performance and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.