This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Bleed Tube 3015385, a component manufactured by Cummins, plays a significant role in the operational efficiency of commercial trucks, particularly within their hydraulic or fuel systems. Cummins, a prominent name in the commercial truck industry, is known for its commitment to quality and innovation, ensuring that components like the Bleed Tube 3015385 meet high standards of performance and reliability 1.

Purpose and Function

The primary function of the Bleed Tube 3015385 is to facilitate the removal of air from a truck’s hydraulic or fuel system. This is essential for maintaining optimal pressure and flow within the system. By allowing air to escape, this Cummins part ensures that the system operates efficiently, preventing issues that could arise from air pockets, such as reduced performance or system failure 2.

Key Features

This part is designed with features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. The precise engineering of the Bleed Tube 3015385 allows it to fit seamlessly within the truck’s system, promoting easy installation and reliable operation. Additionally, its ability to withstand high pressures and temperatures makes it suitable for a wide range of applications 3.

Benefits

Incorporating the Bleed Tube 3015385 into a truck’s system offers several advantages. It contributes to improved system efficiency by ensuring that air is effectively removed, which can lead to better overall performance of the hydraulic or fuel system. Additionally, the Bleed Tube’s durable construction reduces the need for frequent maintenance, offering cost savings and less downtime for commercial truck operators. Its reliable operation in challenging conditions further enhances the dependability of the truck’s systems 4.

Installation and Compatibility

Proper installation of the Bleed Tube 3015385 is key to ensuring its effective operation. While specific installation procedures may vary depending on the truck model and system, general guidelines include ensuring a secure fit within the system to prevent leaks and maintain efficiency. Compatibility with various truck models and systems is a significant advantage, allowing for versatile application across different commercial truck fleets 5.

Maintenance and Troubleshooting

To maintain the Bleed Tube 3015385’s performance, routine checks for signs of wear or damage are recommended. Cleaning the Bleed Tube and ensuring it is free from obstructions can help prevent issues. Common problems may include leaks or reduced efficiency, which can often be addressed by inspecting the fit and condition of the Bleed Tube and making necessary adjustments or replacements.

Safety Considerations

When working with the Bleed Tube 3015385, it is important to follow safety guidelines to ensure personal safety and the proper functioning of the component. This includes handling the Bleed Tube with care to avoid damage, storing it in a dry, cool place to prevent corrosion, and disposing of it according to local regulations if it becomes damaged or reaches the end of its service life.

Cummins Overview

Cummins Inc. has a long-standing reputation in the commercial truck industry for manufacturing high-quality components. Founded with a commitment to innovation and excellence, Cummins offers a wide range of products designed to enhance the performance and reliability of commercial vehicles. The company’s dedication to quality is evident in every component it produces, including the Bleed Tube 3015385, ensuring that commercial truck operators can rely on their equipment for efficient and dependable operation 6.

Role of Bleed Tube 3015385 in Engine Systems

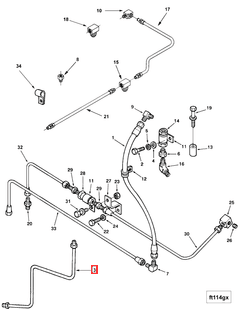

The Bleed Tube 3015385 is integral to the efficient operation of engine systems, particularly in managing the fuel bypass and fuel tubing systems.

In the fuel bypass system, 3015385 allows for the controlled release of excess fuel, ensuring that the system does not become over-pressurized. This helps maintain a stable fuel supply to the engine, enhancing performance and reliability. The Bleed Tube works in conjunction with the fuel bypass tube to redirect surplus fuel back into the fuel tank or to a designated collection point, preventing potential damage to other engine components due to overpressure.

Within the fuel tubing system, the Bleed Tube plays a role in balancing the fuel flow. It helps in equalizing the pressure across different sections of the fuel tubing, which is essential for consistent fuel delivery to the engine. This balance is vital for the engine’s smooth operation, as it ensures that the fuel is delivered at the correct pressure and flow rate, optimizing combustion efficiency and reducing the risk of fuel starvation or over-fueling.

Overall, the integration of the Bleed Tube in these systems underscores its importance in maintaining the integrity and performance of the engine’s fuel management infrastructure.

Conclusion

The Bleed Tube 3015385 by Cummins is a critical component for the efficient operation of commercial truck hydraulic and fuel systems. Its design and features ensure reliable performance, durability, and ease of maintenance. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part. Cummins’ commitment to quality and innovation is reflected in the Bleed Tube 3015385, making it a valuable component for commercial truck operators.

-

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSL9 CM2350 L118. Bulletin Number 4388674.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.