This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

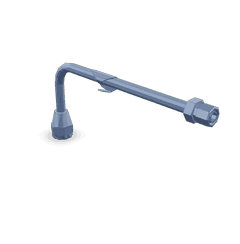

The Cummins Bleed Tube (Part #3025632) is a component designed to facilitate the removal of air from the fuel system of commercial trucks. Its purpose is to ensure that the fuel system operates efficiently by maintaining a consistent flow of fuel to the engine. This component is significant in the operation of commercial trucks as it contributes to the overall performance and reliability of the vehicle.

Basic Concepts and Functionality

Bleed tubes are integral to the fuel systems of many vehicles, including commercial trucks. They operate by allowing air trapped within the fuel lines to escape, which is crucial for maintaining the integrity of the fuel supply 1. When air is present in the fuel lines, it can lead to inefficiencies in the fuel delivery system, potentially causing issues such as engine misfires or reduced power output. The Cummins Bleed Tube plays a role in this system by providing a pathway for air to be expelled, thereby ensuring that the fuel system remains free of air pockets.

Purpose of the Bleed Tube

The Cummins Bleed Tube serves a specific function within the fuel system of a truck. It is designed to remove air that may accumulate in the fuel lines during operation or after maintenance procedures such as fuel filter replacement. By facilitating the escape of air, the bleed tube helps to ensure that the fuel system operates at optimal efficiency. This, in turn, supports the overall performance of the truck by allowing the engine to receive a consistent and uninterrupted supply of fuel.

Key Features

The Cummins Bleed Tube is characterized by several design elements that contribute to its effectiveness and reliability. These include a durable construction that can withstand the pressures and temperatures within the fuel system, as well as a design that allows for easy integration into existing fuel lines. The tube is also engineered to provide a clear pathway for air to escape, which is essential for maintaining the efficiency of the fuel system.

Benefits

Utilizing the Cummins Bleed Tube offers several advantages for commercial truck operators. These include improved fuel system performance, as the consistent flow of fuel to the engine can enhance the truck’s overall efficiency. Additionally, the bleed tube contributes to the reliability of the fuel system by preventing issues related to air in the fuel lines. This can lead to potential cost savings for fleet operators by reducing the likelihood of fuel system-related downtime and the need for repairs 2.

Installation and Integration

Proper installation of the Cummins Bleed Tube is crucial for ensuring its effectiveness within the truck’s fuel system. This process involves preparing the fuel lines for the integration of the bleed tube, which may include cleaning the lines and ensuring that they are free of debris. The installation itself requires careful attention to detail to ensure that the bleed tube is securely connected and that there are no leaks in the system. Tools such as wrenches and sealant may be necessary to complete the installation process.

Troubleshooting and Maintenance

Identifying common issues related to bleed tubes can help in maintaining the efficiency of the fuel system. Diagnostic procedures may involve checking for leaks in the fuel lines or assessing the flow of fuel to the engine. Maintenance practices for the Cummins Bleed Tube include regular inspections to ensure that it remains free of obstructions and that it is functioning as intended. These practices can prolong the lifespan and effectiveness of the bleed tube, contributing to the overall reliability of the truck’s fuel system.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its commitment to innovation and quality in the production of automotive components. With a history of developing reliable and efficient engine components, Cummins has built a reputation for excellence. The company’s dedication to advancing technology and improving the performance of commercial vehicles is evident in its wide range of products, including the Cummins Bleed Tube 3.

Role of Part 3025632 Bleed Tube in Engine Systems

The Bleed Tube part 3025632, manufactured by Cummins, is an integral component in the NH/NT 855 engine series. This part plays a role in the engine’s operation by facilitating the controlled release of air or fuel mixture from the combustion chamber to the exhaust system. Its design ensures that the engine maintains optimal performance and efficiency by managing the pressure within the system.

In the NH/NT 855 engines, the Bleed Tube part 3025632 is specifically engineered to fit seamlessly within the engine’s architecture. It is positioned in such a way that it allows for the precise regulation of the bleed process, which is essential for maintaining the engine’s balance and preventing potential damage from excessive pressure build-up.

The Bleed Tube part 3025632 is also compatible with other Cummins engines within the same series, ensuring a standardized fit and function across the range. This standardization not only simplifies maintenance and repair processes but also enhances the reliability and longevity of the engine components.

Fuel Bypass System Integration

In the fuel bypass system, the Bleed Tube works in conjunction with the Fuel Bypass Mounting Tube and the Fuel Bypass Tube. Its role is to provide a controlled path for excess fuel to be redirected, preventing system overpressure and ensuring consistent fuel delivery to the engine. This is particularly important in high-performance engines where fuel demand fluctuates rapidly.

Fuel Plumbing and Supply

Within the fuel plumbing network, the Bleed Tube is positioned to interact with the Fuel Supply Tubing and the Fuel Pump. It aids in maintaining a stable fuel pressure by allowing a measured amount of fuel to escape, thus balancing the system’s pressure dynamics. This is essential for the Fuel Pump’s efficiency, as it ensures the pump operates within its designed parameters, leading to reliable fuel delivery.

Mounting and Structural Role

The Bleed Tube is also a key element in the Mounting and Fuel Bypass Tube assembly. It is securely mounted to ensure it remains in place under the dynamic conditions of engine operation. This structural integrity is vital for the consistent performance of the fuel bypass system, as any displacement could lead to inefficient fuel management.

Overall System Contribution

In summary, the Part 3025632 Bleed Tube is a fundamental component in the fuel management system of an engine. It ensures that the fuel bypass, plumbing, and supply systems operate harmoniously, contributing to the engine’s overall efficiency, performance, and reliability. Its precise role in pressure regulation and fuel flow management underscores its importance in the complex interplay of engine components.

Conclusion

The Cummins Bleed Tube (Part #3025632) is a critical component in the fuel system of commercial trucks, ensuring efficient operation and reliability. Its role in managing air within the fuel lines and contributing to the overall performance of the vehicle underscores its importance in the automotive industry. Proper installation, maintenance, and understanding of its functionality are essential for maximizing the benefits of this Cummins part.

-

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.