This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

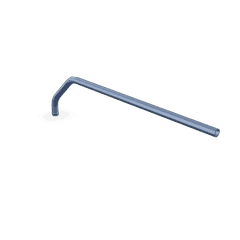

The Cummins 3038035 Breather Tube is a component designed to facilitate the proper functioning of commercial truck engines. Its role is significant in maintaining the engine’s operational efficiency and longevity. This part is integral to the ventilation system of the engine, ensuring that pressure within the engine compartment is balanced and that contaminants are effectively managed.

Basic Concepts of Breather Tubes

A breather tube is a component found in the engine systems of trucks and other vehicles. Its primary function is to allow air to enter and exit the engine compartment as needed, which helps maintain a stable pressure environment. This is crucial for the proper operation of the engine, as it prevents the buildup of excessive pressure that could lead to leaks or damage. The breather tube also plays a role in venting any gases or vapors that may accumulate within the engine compartment, thus contributing to engine health and performance 1.

Purpose of the 3038035 Breather Tube

The Cummins 3038035 Breather Tube serves a specific function within the truck’s engine system. It is designed to facilitate ventilation and pressure equalization within the engine compartment. By allowing air to flow in and out of the engine area, this breather tube helps to maintain an optimal pressure level, which is necessary for the efficient operation of the engine. Additionally, it aids in the removal of any gases or vapors that may form during engine operation, contributing to the overall health and performance of the engine 2.

Key Features

The Cummins 3038035 Breather Tube is characterized by several key features that enhance its performance. It is constructed from durable materials that can withstand the harsh conditions within an engine compartment. The design of the tube includes specific elements that ensure effective air flow and pressure regulation. Additionally, the breather tube may incorporate unique characteristics such as filters or baffles to further improve its functionality and protect the engine from contaminants.

Benefits of Using the 3038035 Breather Tube

Utilizing the Cummins 3038035 Breather Tube offers several advantages. It contributes to improved engine performance by ensuring that the engine operates within an optimal pressure environment. This can lead to enhanced efficiency and power output. Furthermore, the breather tube plays a role in extending the longevity of the engine by preventing damage that could be caused by pressure imbalances. Its reliable operation also adds to the overall reliability of the truck, making it a valuable component for commercial vehicle operators 3.

Installation Process

Installing the Cummins 3038035 Breather Tube requires following a specific procedure to ensure proper functionality. The process involves locating the correct position for the breather tube within the engine compartment, securing it in place using the appropriate fasteners, and connecting it to any necessary components or systems. Tools such as wrenches or screwdrivers may be required, depending on the specific design of the breather tube and the truck’s engine system. It is important to consult the manufacturer’s instructions for detailed guidance on the installation process.

Maintenance Tips

To ensure the optimal functioning of the Cummins 3038035 Breather Tube, regular maintenance practices should be followed. This includes periodic inspection of the breather tube for any signs of damage or wear, as well as cleaning the tube to remove any accumulated debris or contaminants. Inspection intervals may vary depending on the operating conditions and usage of the truck, but it is generally recommended to check the breather tube as part of routine engine maintenance. Following these maintenance tips can help prolong the life of the breather tube and ensure continued efficient operation of the engine.

Troubleshooting Common Issues

Breather tubes, including the Cummins 3038035 model, may encounter common problems that can affect their performance. These issues may include blockages within the tube, leaks, or damage to the tube itself. Troubleshooting these problems involves identifying the specific issue, such as checking for obstructions or inspecting the tube for cracks or holes. Once the problem is identified, appropriate steps can be taken to address it, which may include cleaning the tube, repairing or replacing damaged sections, or ensuring proper installation to prevent leaks.

Regulatory Compliance

The use of breather tubes in commercial trucks is subject to regulatory standards and compliance requirements to ensure safe and legal operation. These regulations may vary by region or country, but they generally aim to maintain the integrity of the vehicle’s engine system and protect the environment from emissions. Operators of commercial trucks should be aware of the specific regulations applicable to their jurisdiction and ensure that the breather tube, including the Cummins 3038035 model, meets these requirements. Compliance with these standards not only ensures the safe operation of the vehicle but also contributes to environmental protection efforts.

About Cummins

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and strong reputation. The company has a history of innovation and quality, offering a variety of engine and component solutions designed to meet the demanding requirements of commercial vehicle operators. Cummins’ product range includes engines, filtration systems, emissions solutions, and aftermarket parts, all aimed at enhancing the performance, efficiency, and reliability of commercial trucks. The company’s commitment to quality and customer satisfaction has earned it a respected position in the industry.

Breather Tube (Part 3038035) in Cummins Engines

The Breather Tube, part number 3038035, is a critical component in Cummins engines, ensuring proper ventilation and pressure management within the engine’s crankcase. This part is designed to facilitate the release of gases and vapors that accumulate during the engine’s operation, thereby preventing pressure build-up that could lead to leaks or damage.

N14 CELECT and N14 CELECT PLUS Engines

In the N14 CELECT and N14 CELECT PLUS engines, the Breather Tube is integral to maintaining the efficiency and longevity of the engine. These engines are known for their robust design and high performance, often used in heavy-duty applications. The Breather Tube in these engines connects the crankcase to the intake manifold, allowing for the safe expulsion of gases and vapors. This connection is crucial for maintaining optimal engine pressure and preventing oil contamination.

N14 MECHANICAL Engine

The N14 MECHANICAL engine, while similar in many aspects to its CELECT counterparts, relies on the Breather Tube to manage crankcase pressure in a slightly different manner. This engine variant is typically found in applications where electronic controls are not as prevalent. The Breather Tube in the N14 MECHANICAL engine also connects the crankcase to the intake manifold, ensuring that any gases or vapors are expelled efficiently. This helps in maintaining the engine’s overall health and performance.

NH/NT 855 Engine

The NH/NT 855 engine, another robust Cummins engine, utilizes the Breather Tube to manage crankcase pressure effectively. This engine is known for its durability and is often used in various industrial applications. The Breather Tube in the NH/NT 855 engine is designed to connect the crankcase to the intake manifold, ensuring that any gases or vapors are expelled safely. This connection is vital for maintaining the engine’s efficiency and preventing potential damage from pressure build-up.

In all these engines, the Breather Tube plays a pivotal role in maintaining the engine’s health and performance by ensuring that the crankcase pressure is managed effectively. This component is essential for the longevity and reliability of the engine, making it a critical part in Cummins’ lineup of heavy-duty engines.

Role of Part 3038035 Breather Tube in Engine Systems

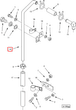

The part 3038035 Breather Tube is an essential component in the breather arrangement of various engine systems. It is specifically designed to facilitate the efficient management of gases within the crankcase.

In the crankcase breather system, the Breather Tube allows for the release of gases that accumulate within the crankcase. This is important for maintaining the proper pressure levels and ensuring that the engine operates smoothly. The tube is connected to the breather and valve cover, which are responsible for capturing and directing these gases away from the engine.

The breather arrangement, which includes the EBM (Engine Breather Module) and the vent mounting tube, relies on the Breather Tube to provide a clear path for the expelled gases. This setup helps in preventing the buildup of pressure that could lead to oil leaks or other mechanical issues.

Additionally, the mounting and breather tube configuration ensures that the Breather Tube is securely attached to the engine, allowing for stable and reliable performance. The vent tube, which is often part of this arrangement, works in conjunction with the Breather Tube to ensure that all excess gases are properly vented from the system.

Overall, the integration of the part 3038035 Breather Tube within these components plays a significant role in the overall efficiency and longevity of the engine system.

Conclusion

The Cummins 3038035 Breather Tube is a vital component in the maintenance and operation of commercial truck engines. By facilitating proper ventilation and pressure management within the engine compartment, this part contributes to the engine’s efficiency, performance, and longevity. Regular maintenance, proper installation, and adherence to regulatory standards are essential for ensuring the optimal functioning of the breather tube and the overall reliability of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.