This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3048336 Bleed Tube is a component designed for use in commercial trucks, specifically within the fuel system. Its purpose is to facilitate the removal of air from the fuel lines, ensuring a consistent and efficient fuel supply to the engine. This component is significant in maintaining the operational integrity of the truck’s fuel system, contributing to overall engine performance and reliability 1.

Basic Concepts and Functionality

A bleed tube, in general, is a component used in various systems to allow the escape of air or gases. Within a truck’s fuel system, the bleed tube operates by providing a pathway for air to be expelled from the fuel lines during the priming process. This ensures that the fuel system is free of air pockets, which can impede fuel flow and affect engine performance. The efficient operation of the bleed tube is integral to maintaining system efficiency and ensuring that the engine receives a steady supply of fuel 2.

Purpose of the Cummins 3048336 Bleed Tube

The Cummins 3048336 Bleed Tube plays a specific role in the operation of a truck by aiding in the removal of air from the fuel system. This is particularly important during the initial setup or after maintenance when air may have entered the fuel lines. By allowing air to escape, the bleed tube helps to establish a continuous fuel path, which is vital for the engine’s consistent operation. Its function within the overall system is to enhance fuel delivery efficiency and support the engine’s performance under various operating conditions 3.

Key Features

The Cummins 3048336 Bleed Tube is characterized by several design elements and materials that contribute to its performance. It is constructed from durable materials to withstand the pressures and conditions within the fuel system. The design includes specific fittings and connections that ensure a secure and leak-free installation. Additionally, the bleed tube may feature unique characteristics such as a built-in filter to prevent contaminants from entering the fuel system, enhancing the overall reliability of the component.

Benefits

The advantages provided by the Cummins 3048336 Bleed Tube include improved system performance, reliability, and efficiency. By ensuring that the fuel system is free of air, the bleed tube contributes to a more consistent fuel supply to the engine. This can lead to better engine performance, reduced risk of fuel-related issues, and overall system reliability. The component’s design and materials also contribute to its durability and longevity, offering value to truck operators through reduced maintenance needs and enhanced operational efficiency.

Installation Considerations

When installing the Cummins 3048336 Bleed Tube, it is important to follow guidelines and best practices to ensure proper function and integration within the fuel system. Preparatory steps may include cleaning the installation area and ensuring that all connections are secure and free from debris. The use of appropriate tools and following the manufacturer’s instructions can help achieve a successful installation, contributing to the component’s effectiveness and the system’s overall performance.

Troubleshooting Common Issues

Typical problems that may arise with the Cummins 3048336 Bleed Tube include air leaks, blockages, or damage to the component. Diagnostic steps may involve checking for visible signs of damage, ensuring all connections are secure, and verifying that the bleed tube is functioning as intended. Solutions may range from tightening connections to replacing the component if it is found to be damaged or malfunctioning. Regular inspection and maintenance can help identify and address issues before they lead to significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3048336 Bleed Tube, routine maintenance is recommended. This may include periodic inspection for signs of wear or damage, ensuring that all connections remain secure, and cleaning the component as necessary to prevent the buildup of contaminants. Following the manufacturer’s maintenance guidelines can help maintain the bleed tube’s efficiency and contribute to the overall reliability of the truck’s fuel system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and commitment to quality, Cummins has established itself as a key player in the commercial truck industry. The company’s focus on developing reliable and efficient components, such as the Cummins 3048336 Bleed Tube, underscores its dedication to supporting the performance and longevity of commercial vehicles.

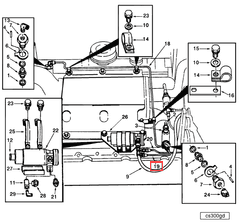

Cummins Bleed Tube Part 3048336 in Engine Models

The Bleed Tube part 3048336, manufactured by Cummins, is a critical component in several engine models. This part is integral to the engine’s operation, ensuring efficient and reliable performance.

V903 Engine Series

In the V903 engine series, the Bleed Tube part 3048336 is designed to manage the pressure and flow of fluids within the engine. Its precise fit and function are crucial for maintaining the engine’s overall performance and longevity.

Application in Engine Models

- V903 Engine: The Bleed Tube part 3048336 is specifically engineered to fit seamlessly within the V903 engine. Its role is to regulate the fluid dynamics, ensuring that the engine operates smoothly and efficiently.

- Other Cummins Engines: While the V903 is highlighted here, the Bleed Tube part 3048336 is also compatible with other Cummins engine models. Its design allows for a universal fit, ensuring that it can be used across various engine types without compromising performance.

Importance of the Bleed Tube

The Bleed Tube part 3048336 is essential for the following reasons:

- Pressure Regulation: It helps in maintaining the correct pressure levels within the engine, preventing potential damage from overpressure.

- Fluid Flow: Ensures that fluids are directed correctly, enhancing the engine’s efficiency and reducing wear and tear.

- Durability: Made from high-quality materials, this part is built to withstand the harsh conditions within the engine, ensuring a long service life.

Installation and Maintenance

Proper installation of the Bleed Tube part 3048336 is critical. Technicians should follow the manufacturer’s guidelines to ensure that the part is fitted correctly. Regular maintenance checks are also recommended to ensure that the Bleed Tube remains in optimal condition, contributing to the engine’s overall reliability.

Role of Part 3048336 Bleed Tube in Engine Systems

The part 3048336 Bleed Tube is an integral component in various engine systems, facilitating efficient operation and performance. Its role can be observed in the following systems:

Air Intake System

In the Air Intake system, the Bleed Tube aids in managing airflow dynamics. It helps in maintaining optimal air pressure levels, which is essential for the efficient combustion process. By regulating the air bleed, it ensures that the correct air-fuel mixture reaches the combustion chamber, contributing to smooth engine operation.

Fuel Injection System

Within the Fuel Injection system, the Bleed Tube plays a significant role in ensuring consistent fuel delivery. It helps in bleeding off excess fuel pressure, which is vital for maintaining the precision of fuel injection. This ensures that the fuel injectors operate within their specified parameters, leading to improved fuel efficiency and reduced emissions.

Starting System

In the Starting system, particularly with the Injection Starting mechanism, the Bleed Tube assists in priming the fuel system. It helps in removing air pockets that may form in the fuel lines, ensuring a consistent fuel supply to the injectors during engine start-up. This is particularly important in cold start conditions where fuel viscosity is higher.

Cold Start System

For the Cold Start system, the Bleed Tube is essential in facilitating quick and reliable engine starts in low-temperature environments. It helps in managing the fuel pressure and ensuring that the fuel system is adequately primed. This is crucial for the Cold Start Mounting Pump to function effectively, delivering the necessary fuel volume to overcome the increased viscosity and ensure smooth engine ignition.

Mounting Pump System

In systems utilizing a Mounting Pump, the Bleed Tube ensures that the pump operates under optimal conditions. By managing the pressure within the fuel lines, it prevents cavitation and ensures consistent fuel delivery. This is particularly important for high-performance engines where precise fuel metering is required for optimal power output and efficiency.

Conclusion

The Cummins 3048336 Bleed Tube is a vital component in the fuel systems of commercial trucks, ensuring efficient and reliable engine performance. Its role in removing air from the fuel lines, regulating pressure, and facilitating consistent fuel delivery is crucial for the overall operation of the engine. Proper installation, maintenance, and understanding of its function within various engine systems are essential for maximizing the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.