This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Bleed Tube 3065166, manufactured by Cummins, is a critical component for commercial trucks, designed to enhance operational efficiency by facilitating the removal of air from the fuel system. This ensures consistent fuel delivery and optimal engine performance 1.

Basic Concepts of Bleed Tubes

Bleed tubes are essential in various truck systems, particularly the fuel system, to allow the escape of air that may accumulate. The presence of air can lead to inefficient fuel delivery and engine performance issues. By providing a pathway for air to exit, bleed tubes help maintain system integrity and efficiency 2.

Purpose of Bleed Tube 3065166

This Cummins part is specifically designed to remove air from the fuel system of commercial trucks. It ensures minimal air content in the system, contributing to consistent fuel delivery and optimal engine performance. The Bleed Tube 3065166 is integral to the fuel system’s operation, ensuring a steady fuel supply without interruptions caused by air pockets 3.

Key Features

The Bleed Tube 3065166 is constructed from high-quality materials that resist corrosion and wear, ensuring durability in demanding environments. Its design includes features for easy installation and maintenance, as well as efficient air removal from the fuel system.

Benefits of Using Bleed Tube 3065166

Incorporating this part into truck systems offers several advantages, including improved engine efficiency through consistent fuel supply. The design and material of the bleed tube enhance the reliability of the fuel system, reducing performance issues related to air in the fuel lines. Additionally, its ease of installation and maintenance simplifies system upkeep, contributing to overall vehicle reliability.

Installation Considerations

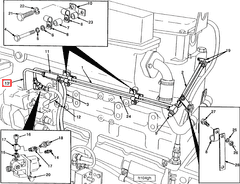

When installing the Bleed Tube 3065166, it is important to follow manufacturer guidelines for compatibility with the specific truck model and fuel system. Proper installation involves securing the bleed tube in the correct position within the fuel system to facilitate effective air removal. It is also important to verify that all connections are secure to prevent leaks and ensure system integrity.

Troubleshooting Common Issues

Common issues associated with bleed tubes include air accumulation in the fuel system, which can lead to engine performance problems. Diagnostic steps may involve inspecting the bleed tube for blockages or damage and ensuring it is correctly installed. Maintenance actions may include cleaning or replacing the bleed tube to restore efficient operation of the fuel system.

Maintenance Tips

Routine maintenance of the Bleed Tube 3065166 involves regular inspection for signs of wear or damage and ensuring that it remains free of obstructions. Cleaning the bleed tube as part of regular fuel system maintenance can help prevent issues related to air accumulation. Following manufacturer-recommended inspection intervals and maintenance procedures will help ensure the longevity and optimal performance of the bleed tube.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves commercial, industrial, and automotive markets worldwide. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of various applications. Cummins’ dedication to innovation and customer satisfaction has established it as a trusted name in the automotive and engine manufacturing industry.

Role of Part 3065166 Bleed Tube in Engine Systems

The Bleed Tube 3065166 is an integral component in the efficient operation of various engine systems, particularly in the management and regulation of fuel and bypass systems. Its application spans across several key components, ensuring optimal performance and safety.

Integration with Bypass Mounting Tube

In the context of the Bypass Mounting Tube, 3065166 plays a significant role in pressure regulation. It facilitates the controlled release of excess pressure, which is essential for maintaining the structural integrity and operational efficiency of the Bypass Mounting Tube. This is particularly important in high-stress environments where pressure fluctuations can lead to component failure.

Function in Fuel Bypass Mounting Tube

When integrated with the Fuel Bypass Mounting Tube, the Bleed Tube aids in the precise management of fuel flow. It ensures that any surplus fuel is effectively diverted, preventing potential overflow and maintaining a consistent fuel supply to the engine. This is vital for the engine’s performance, as it ensures that the fuel system operates within its designed parameters, thereby enhancing overall engine efficiency.

Role in Fuel Tubing

In the Fuel Tubing system, the Bleed Tube is employed to manage pressure within the fuel lines. It allows for the safe release of built-up pressure, which is crucial for the longevity and reliability of the Fuel Tubing. This function is especially important in systems where fuel is transported under high pressure, as it helps in preventing leaks and ensuring a steady fuel supply to the engine.

Overall Impact on Engine Systems

The incorporation of the Bleed Tube in these systems not only enhances their individual performance but also contributes to the overall reliability and safety of the engine. By effectively managing pressure and flow, it ensures that each component operates within its optimal range, leading to improved engine performance and longevity.

Conclusion

The Bleed Tube 3065166 by Cummins is a vital component for maintaining the efficiency and reliability of commercial truck fuel systems. Its role in removing air, managing pressure, and ensuring consistent fuel delivery is crucial for optimal engine performance. Proper installation, maintenance, and troubleshooting of this part are essential for the longevity and safety of engine systems.

-

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE Books, 2023.

↩ -

Michael Klyde and Kirk VanGelder, Advanced Automotive Electricity and Electronics, Jones Bartlett Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.