3067570

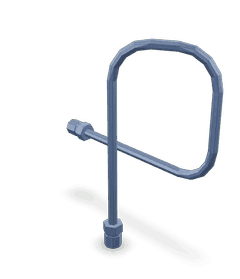

Pressure Sensing Tube

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3067570 Pressure Sensing Tube is a vital component in commercial trucks, integral to the engine management system. Understanding its function and role is essential for maintaining and optimizing truck performance.

Basic Concepts of Pressure Sensing Tubes

Pressure Sensing Tubes facilitate the measurement and regulation of pressure within engine systems. They convey pressure readings from various engine points to the management system, enabling adjustments for optimal performance. These tubes provide real-time data crucial for engine management and efficiency 1.

Purpose of the 3067570 Pressure Sensing Tube

The Cummins 3067570 Pressure Sensing Tube monitors and regulates engine pressure, ensuring operation within specified parameters. This is vital for maintaining engine efficiency, performance, and longevity. Accurate pressure readings allow the engine management system to make necessary adjustments for smooth and reliable operation 2.

Key Features

This Cummins part is characterized by its robust design and quality materials, enhancing durability and performance. It is engineered to withstand harsh conditions within a commercial truck engine, ensuring reliable operation over time. Its design facilitates easy integration into the engine system, minimizing installation and maintenance complexity 3.

Benefits

The advantages of the 3067570 Pressure Sensing Tube include improved engine efficiency, enhanced performance, and increased reliability. It contributes to better fuel efficiency and reduced emissions by ensuring the engine operates within optimal pressure parameters. Its reliable operation maintains consistent engine performance, reducing the likelihood of unexpected failures 4.

Installation and Integration

Installing the 3067570 Pressure Sensing Tube requires following manufacturer guidelines for compatibility and optimal performance. Adjustments may be necessary for seamless integration into the existing engine management system.

Troubleshooting and Maintenance

Common issues with the 3067570 Pressure Sensing Tube include blockages, leaks, or inaccurate readings. Diagnostic procedures involve checking for these issues and making necessary repairs or replacements. Regular maintenance, such as cleaning and inspecting the tube, ensures optimal performance and longevity. Following manufacturer recommendations for maintenance can prevent many issues.

Performance Impact

The 3067570 Pressure Sensing Tube affects the overall performance of the truck by contributing to fuel efficiency, power output, and emission levels. Accurate pressure readings allow the engine management system to make adjustments that optimize these aspects of performance. Its role in maintaining engine pressure within specified parameters is key to achieving efficient and reliable operation.

Safety Considerations

When working with the 3067570 Pressure Sensing Tube, it is important to observe safety guidelines and precautions to prevent accidents and ensure safe operation. This includes following proper installation and maintenance procedures, using appropriate tools and equipment, and being aware of the potential hazards associated with engine systems.

Cummins Overview

Cummins is a well-established company in the commercial truck industry, known for its commitment to quality and innovation. Its products, including the 3067570 Pressure Sensing Tube, are designed with a focus on durability, performance, and compatibility with a wide range of commercial truck applications.

Role of Part 3067570 Pressure Sensing Tube in Engine Systems

The 3067570 Pressure Sensing Tube is integral to monitoring and maintaining the operational efficiency of various engine systems. Its primary function is to accurately measure and relay pressure data from specific points within the engine to the control systems.

Integration with the Pump System

In pump systems, the Pressure Sensing Tube monitors pressure levels within the pump housing. This data is essential for ensuring the pump operates within its designed parameters. By providing real-time pressure readings, the tube allows for the early detection of anomalies such as cavitation or blockages, enabling timely maintenance and preventing potential pump failure.

Application in Lubricating Oil Systems

Within lubricating oil systems, the Pressure Sensing Tube maintains optimal lubrication conditions. It is typically installed in the oil galleries or at the oil filter to monitor pressure levels. Consistent pressure readings are vital for ensuring that the oil is adequately circulating through the engine, providing necessary lubrication to moving parts and reducing wear and tear.

The data from the Pressure Sensing Tube helps in detecting issues such as oil starvation or filter clogging, allowing for prompt corrective actions to be taken. This ensures that the engine components remain well-lubricated, enhancing overall engine performance and longevity.

Conclusion

The Cummins 3067570 Pressure Sensing Tube is a critical component in commercial truck engine systems, contributing to engine efficiency, performance, and reliability. Its accurate pressure monitoring and robust design make it essential for maintaining optimal engine operation and longevity.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

The Evolution of Automotive Engineering: A Handbook, Gijs Mom, SAE International, 2023.

↩ -

A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition, Allan Bonnick and Derek Newbold, Elsevier Ltd, 2011.

↩ -

Chassis and Axles, Michael Hilgers, Springer Vieweg, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.